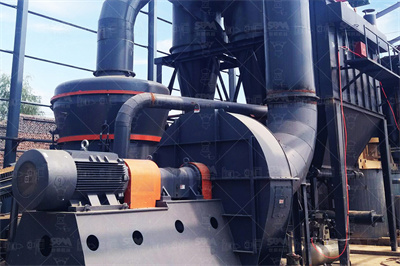

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2021年12月9日 · 2023清明节即将道路,正是踏青好时节。那么清明假期去哪里踏青呢?上海及周边古镇是不错的选择,一起来看,你想去哪?2024朱家角古镇游玩攻略(门票+游玩指南) 来上海想要感受江南水乡,就去朱家角古镇,上海朱家角古镇有哪些景点?门票多少钱?

朱家井村地处北纬36°49′,东经119°56′,位于平度城北牛山东侧,距平度市人民会堂6公里。 村东与双庙村接壤,西邻夼村、南与毛家疃、西七里河子村相望,北倚花窝洛村,全村总面积平方公里。

2023年9月22日 · 井亭位于朱家角镇西井街56号,井亭民宿改造前是杨氏古宅,始建于清代(十九世纪末),有100 多年历史,因其重要的历史价值、艺术价值被上海市政府公布为优秀历史建筑。这座占地760多平方米的古宅是一座典型的三进式中式庭院建筑,一重 ...

襄阳诸葛草庐位于襄阳市古隆中景区,隆中山畔三顾堂后坡上,始建于清朝康熙五十九年(公元1720年),初建时是草亭,民国年间改为瓦亭。襄阳诸葛草庐是诸葛亮当年在隆中卧读躬耕、生活起居之处,呈六角形,双层飞檐,碧柱红瓦,亭中一块大石碑上刻有"草芦"两个大字,字体苍劲端 .

2018年1月25日 · 坐到景区的南门或北门下来,走几步就是热闹的朱家角核心区了。如果你还是小时候去的朱家角,那么现在 ... 我们的吃吃吃之旅,就从西井街、东井街和北大街开始。朱家 角让我知道:景区里的饭,真的不难吃啊。放生桥南北两侧的土菜馆加 ...

2021年12月9日 · 2023清明节即将道路,正是踏青好时节。那么清明假期去哪里踏青呢?上海及周边古镇是不错的选择,一起来看,你想去哪?2024朱家角古镇游玩攻略(门票+游玩指南) 来上海想要感受江南水乡,就去朱家角古镇,上海朱家角古镇有哪些景点?门票多少钱?

2025年4月23日 · 朱家村改名为珠街阁,又名珠里、珠溪,俗称角里。1949年建国后,成立苏南行政公署松江专区青浦县朱家角市,下辖沈港、万龙、葑沃、薛间四乡及朱家角镇。原属昆山县的东井亭、中井亭、西井亭三条街划归朱家角镇。

2021年9月6日 · 朱家角地处江、浙、沪二省一市的交通枢纽,北连昆山,南接嘉善,西通平望。朱家角之地,大约成陆于7000年前,淀山湖底发现有新石器时代至春秋战国时代的遗物。唐朝以 .

2025年2月2日 · 上海几大古镇中,位于青浦淀山湖畔的朱家角是最大的,平日里就游客摩肩接踵、不亦乐乎。 但是在游客稀少之际,古镇逐步恢复了本来的面貌,居民替代了游客,成为古镇的 .

2023年5月3日 · 朱家角古镇 朱家角古镇位于上海市 青浦区,是上海四大历史文化名镇之一,素有" 江南明珠 "之称。 朱家角总面积平方公里(含水域),拥有较具古镇特色的人文景观,即一桥、一街、一寺、一庙、一厅、一馆、二园、三湾、二十六弄,呈现出"小桥、流水、人家"的江南水乡古朴风貌。

百草园(Baicao Garden)是浙江绍兴新台门周家的一个菜园,位于浙江绍兴的鲁迅故居后面,北临东咸欢河,东邻沈姓房屋,西接梁家后园,南宽北狭,占地近2000平方米。百草园原来是新台门周家的智、仁两大房族所共有。这个荒芜的园子,不仅瓦砾成堆,杂草丛生,而且有树木、蔓藤和飞鸟虫兽,是 ...

上饶_朱家井地址_朱家井位置地图"这里早以前不叫'朱家井',我听家里的老人说,是因为几百年前有户朱姓人家在村里打了一口井,井水和现在这口井一样,也是向上涌的,水源源源不断,解决了很多老百姓的。友。

2016年10月28日 · 1912年,时年52岁的马文卿来到朱家角井亭港,择地百亩,开始兴建当地人称"马家花园"的"课植园"。 这位原籍江西的成功商人,在人生过半的时候,捐官道台,并在这非故非亲的朱家角定居,以兴建这座规模恣肆的园林消磨人生,以"课植"为名。

泗水亭是位于江苏省徐州市沛县的景点,汉代开国皇帝刘邦就曾做过"泗水亭长"。汉代开国皇帝刘邦就曾做过"泗水亭长"。泗水亭公园大门内侧飞檐下题写着"千古龙飞地",这正是古沛的别称。除了汉高祖刘邦外,沛县人还会提到另一位开国皇帝,即明朝的朱元璋,朱元璋的祖籍也是沛县 ...

2024年2月16日 · 朱家峪旅游区,位于济南市章丘区经十路东路南侧,是中国北方地区典型的山村型古村落。景区共有大小古建筑近200处,大小石桥30余座,井泉20余处,庙宇10余处,主要景点包括康熙双桥、文昌阁、魁星楼、关帝庙、朱氏家祠等,区内四面青峰隐隐,溪中碧水悠悠,悠久的历史文化,多姿多彩的风景 ...

2023年2月3日 · 如果坐公共交通,推荐的方式坐地铁17号线,东方绿舟方向,到朱家角站下车。 2号线和17号线共用了一个入口,往浦东方向的是2号线,一侧向朱家角东方绿舟方向的,即17 .

吉安府是明清时期设置的一个府,位于江西省中部。隋开皇十年(公元590年),庐陵郡改为吉州,后来多次在庐陵、吉州两名间反复改称。元朝元贞元年(1295年),改吉州路为吉安路,"吉安"之名自此始。吉安府:明太祖壬寅年(公元1362年),废路为府,治庐陵县(今江西吉安市)。

2017年9月4日 · 王家井 :王家井村、火烧王、大砚石、宣顶、霞中、箬山下、西沙、文周、风仪楼、寺前、下坟、稻蓬山、塘口。 牌头 :小砚石、长潭、楼瑶驾、宝稼塘、长潭街、上楼宅、坑西。 安华 :涨墟。 街亭 :街亭、朱曹坞、老龙、黎明。

2023年9月11日 · 17号线朱家 角站——珠溪路——祥凝浜路——新风路——朱家角古镇游客中心(慈门街)——放生桥(★)——东井街(阿婆肉粽、橘子饼、中草药香囊、酱园、拇指生煎、朱市大集(★))——西井街(花酿、雪梨汤、永 ...

凤阳府,明洪武七年明太祖朱元璋改中立府为凤阳府,同年府治由古濠州城前往新建的明中都城,凤阳是朱元璋出生并生长的地方,凤阳府治今凤阳县城。凤阳府下辖五州十三县,亳州、宿州、颍州、泗州和寿州五州,明代隶属于南直隶,清代隶属于江南省和安徽省,1913年废府留县,置凤 .

2023年4月12日 · 中国石化新闻网讯 3月29日,江苏油田朱家 墩储气库首口储气井——朱储11 井顺利完井,完钻垂深达3835米,创 长三角地区储气井最深纪录。 作为保障长三角地区供气需求 的重点建设工程,朱家墩储气库设计 库容亿立方米,工作气量亿 立方米,建成后将提升长三角地区天 然气季节调峰和应急 ...

2023年9月24日 · 井亭位于朱家角镇西井街56号,井亭民宿改造前是杨氏古宅,始建于清代(十九世纪末),有100 多年历史,因其重要的历史价值、艺术价值被上海市政府公布为优秀历史建筑。这座占地760多平方米的古宅是一座典型的三进式中式庭院建筑,一重 ...