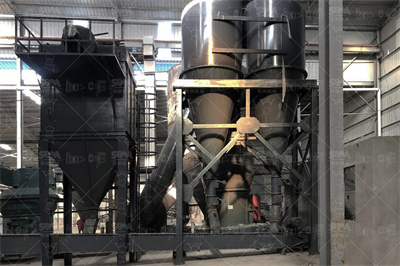

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2014年5月22日 · 广东奶豆茶糖加盟鼎好食品招商网汇集各种广东奶豆茶糖招商、加盟、代理、采购、批发新品货源信息,更多广东奶豆茶糖招商代理尽在鼎好食品招商网,最新的广东奶豆茶糖招商信息:新南牌出口装单晶冰糖400g,供应优质黄冰糖碎,手撕牛排,一元装休闲零食找经销代理商。

我的钢铁网为您提供4月2日Mysteel昆明建筑钢材价格指数,包含昆明高线,盘螺,螺纹钢市场价格,让您轻松了解昆明建筑钢材市场行情,助您快人一步,掌握商机。

2025年4月10日 · 【备注】 1、如无特殊说明,以上表列钢厂资源为过磅; 2、以上基准采集价格为现款、含税、仓库自提价格,不含出库费; 3、表列涨跌幅为与前一交易日收盘价相比价差,当日价差以累计计算。

2025年4月20日 · 广东 广州 韶关 深圳 珠海 汕头 佛山 江门 湛江 茂名 肇庆 惠州 梅州 汕尾 河源 阳江 清远 东莞 中山 潮州 揭阳 云浮 成色: 不限 9成新以上 8~9成新 7~8成新 7成新以下 全新 供求: 不限 转让 求购 回收 已选择: 二手烘干机 广东 转让

2025年4月7日 · 品种:矿渣硅酸盐水泥;强度等级:;包装形式:散装 t 查看价格 查看价格 华星 廊坊 廊坊三河华星水泥有限公司 水泥 普通硅酸盐水泥散装(都安基地) t .

食品商务网提供广东价格、广东品牌、广东厂家等优质信息,可按产地货源、公司规模筛选。最新相关广东发布信息:安琪广式月饼、广州各大食堂冬季蔬菜基地直采,货源充足,送货上门、椰椰拿铁冻冻冻干麦片盒马同款多种口味可定制等

菱镁矿粉 产品信息 搜索 武汉拉那白医药化工有限公司 第 9 年 湖北 武汉市 主营产品: 全氟三丁胺 轻氟油F113 丙酸氯倍他索 醋酸氯己定 葡萄糖酸氯己定 1,3二羟基丙酮 ...

2025年4月17日 · 免责声明:Mysteel力求使用的信息准确、信息所述内容及观点的客观公正,但并不保证其是否需要进行必要变更。Mysteel提供的信息仅供客户决策参考,并不构成对客户决策的直接建议,客户不应以此取代自己的独立判断,客户做出的任何决策与 ...

我的钢铁网提供2025年03月19日上海冷轧基料价格行情,包含上海冷轧基料市场价格、上海冷轧基料最新报价,让您轻松了解上海冷轧基料市场行情,助您快人一步,掌握商机。

广东速冻面点、西点加盟鼎好食品招商网汇集各种广东速冻面点、西点招商、加盟、代理、采购、批发新品货源信息,更多广东速冻面点、西点招商代理尽在鼎好食品招商网,最新的广东速冻面点、西点招商信息:鱼旦,点心加盟免费培训,广州点心加盟免加盟费。

6 天之前 · 水泥网为您提供今日广东惠州水泥价格表,还有水泥散装、袋装、参考价格以及广东惠州水泥供求信息供您参考。 更多广东惠州水泥最新及历史价格欢迎您到行情通查看。

4 天之前 · 其中碎石销量万吨,占总销量的48%;机制砂销量万吨,占总销量的43%;石粉销量万吨,占总销量的9%本周广东砂石出货量略有回暖,重点会议结束后,部分城市项 .

2025年4月23日 · 以前只做电厂,现在下游布局了十几个码头,是汕尾电厂粉煤灰的一级经销商,今年粉煤灰源头批发价格比去年整体下降了30几块钱 后市看法:目前市场行情整体不温不 .

2024年1月21日 · 东莞华润水泥厂有限公司的地址为东莞市沙田镇福禄沙村,位于广东东莞东莞市辖区,广东省东莞东莞市辖区胜利社区,注册于1994年5月23日,法人是程实,公司社保参保人数153人,主要业务范围为生产和销售高标号优质水泥、超细矿渣微粉(涉及许可证的项目,须领证后才能经营)。

2 天之前 · 【木联日报:原木期货行情及成交持仓排名()】据大连商品交易所(DCE)公布的数据显示,以下为2025年4月30日原木主力合约(lg2507)行情及成交持仓情 .

本页面提供2011年04月25日用户发布B2B信息, 包括工程机械二手、工程机械配件、工程机械租赁、工程机械维修等信息,买卖设备上中国路面机械网。

食品商务网企业栏目提供广东 黄黄厂家,黄黄品牌,黄黄公司信息可按地区、注册资金、成立时间、厂家筛选优质供货商。 找黄黄上食品商务网。 欢迎来到食品商务网, 登录 免费注册

2014年10月29日 · Title 附件1: 广东省化妆品监督抽验信息(2019年第6期,不合格产品68批) Author gdfda Last modified by chenning Created Date 10/29/2014 12:08:00 PM

2025年3月21日 · 今日广州市场镀锌管价格信息采集点数量41个,有效采集样本量12个,市场主流品牌价格范围4730~4900元/吨(以Q215235 4寸* 的含税库提价格为基准),成交数 .

2025年3月25日 · 免责声明:Mysteel力求使用的信息准确、信息所述内容及观点的客观公正,但并不保证其是否需要进行必要变更。Mysteel提供的信息仅供客户决策参考,并不构成对客户决策的直接建议,客户不应以此取代自己的独立判断,客户做出的任何决策与 ...

2025年2月12日 · 备注:1、以上基准采集价格均为预应力钢丝过磅价格; 2、以上基准采集价格为现款含税、不含吊装费、当地市场自提价格; 3、如未特别注明,以上预应力钢丝基准采集价格为螺旋肋钢丝价格; 4、以上涨跌幅为与前一交易日收盘价相比价差;

我的钢铁网提供2025年04月03日郑州镀锌管价格行情,包含郑州镀锌管市场价格、郑州镀锌管最新报价,让您轻松了解郑州镀锌管市场行情,助您快人一步,掌握商机。

3 天之前 · 04月29日广东汕尾混凝土市场价格行情,中南混凝土价格指数为,下跌:0。最新汕尾混凝土价格欢迎查看! 行情通首页 项目 水泥价格 混凝土价格 矿渣微粉 ...

2024年8月14日 · 免费查询更多河南矿渣粉经销商详细参数、实时报价、行情走势、优质商品批发/ 供应信息等,您还可以发布询价信息。 欢迎来到爱采购,百度旗下B2B平台!登录/注册 百度爱采购首页 购物车 ...