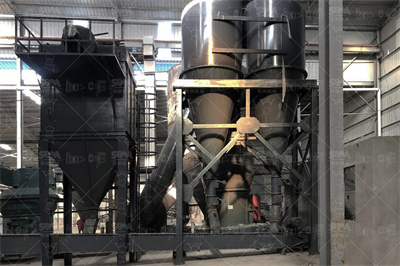

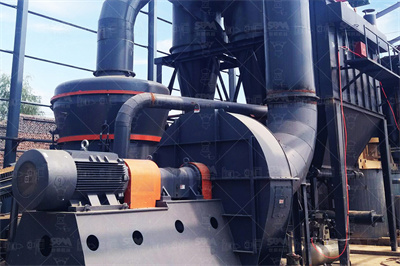

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2025年3月1日 · 您在查找德西米兰凯斯特石英石吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

2021年8月17日 · 德希米尔石英石是中国石英石行业品牌,是一家新型建筑及装饰材料研发、生产、销售、服务为一体的专业企业。 公司设有华北华南两个生产基地,一期占地面积24000平方 .

成功研制650 x 650mm渗花瓷质砖,渗花石英 抛光砖荣获"国家级新产品"、"市科技进步奖二等奖"。 1988 立体印花彩釉砖 ... 鹰牌陶瓷 / 超现石S 米兰灰 Y1GL27WE 产品创意: 米兰灰源于意 .

2020年5月15日 · 石英石高新技术自05年最早开始引进中国,德希米尔公司已引领创办中国行业内最早和为数不多的专业大型石英石品牌企业之一。德希米尔石英石 品牌自创立以来,以高端品 .

2011年7月1日 · 德西米兰石英石 质量怎么样我知道,那个很不错的。 百度首页 商城 注册 登录 网页 资讯 视频 图片 知道 文库 贴吧 采购 地图 更多 搜索答案 我要提问 德西米兰石英石质量怎么 .

阿里巴巴为您找到589条石英石米兰产品的详细参数,实时报价,价格行情,优质批发/ 供应等信息。 共 589件 石英石米兰 相关产品 所有类目 实力商家 买家保障 进口货源 支持支付宝 材质保 .

2022年8月10日 · 德希米尔(大中华区)官网河南石英石生产厂家批发——德希米尔石英石是中国河南郑州石英石丨河南郑州石英石厂家、批发、代理丨郑州哪里有卖石英石的河南郑州石英石丨河 .

2025年1月30日 · 石材助手 · 中国石材网APP平台 —— 提供大理石、花岗岩、人造石、奢石、岗石、微晶石、岩板、石英石等石材厂家、石材加工厂、石材矿山、石材图片、石材机械、石材工 .

2025年1月9日 · 免费查询更多德西米澜石英石厂家详细参数、实时报价、行情走势、优质商品批发/ 供应信息等,您还可以发布询价信息。 欢迎来到爱采购,百度旗下B2B平台!登录/注册 百度 .

2020年2月6日 · 狭义上的大理石现在只在瑞士的一个地方开采:在提契诺的Maggia山谷中,来自Peccia的浅色Cristallina大理石。相比之下,古代意义上的彩色大理石,即可打磨的彩色硬 .

2024年9月20日 · 您在查找德西米兰石英石图片吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

广东中旗新材料股份有限公司:绿色环保的新型装饰材料提供者,集绿色环保人造石材研发、制造、综合服务为一体的高新技术企业,中国首家A股主板上市的人造石材企业,中国人造石(石 .

2020年1月6日 · 德西米兰石英石质量怎么样我知道,那个很不错的。英石主产于英德市望埠镇同心村的英山。英石是经大自然的千百年骤冷曝晒、箭雨风刀、神工鬼斧雕塑而成的玲珑剔透的石灰 .

2019年3月4日 · 狭义上的大理石现在只在瑞士的一个地方开采:在提契诺的Maggia山谷中,来自Peccia的浅色Cristallina大理石。相比之下,古代意义上的彩色大理石,即可打磨的彩色硬 .

2025年4月9日 · 意甲联赛历届金靴,劳塔罗加冕本赛季金靴。 2023/24赛季意大利足球甲级联赛38轮比赛战罢,国际米兰加冕联赛冠军,AC米兰、尤文图斯、亚特兰大、博洛尼亚分列二到 .

2016年3月14日 · 1、过程 最近准备装修房子,房子里面有一个中厨和一个西厨,看了很多装修帖子都说石英石的水槽的不错,准备在西厨中使用石英石的水槽。很多人说德国铂浪高Blanco的水 .

2025年3月9日 · 德希米尔石英石的质量还是不错的,这个品牌所出售的石英石防潮防裂效果较好,而且使用寿命较长久,很多家庭在装修的时候可能会选择它,毕竟用石英石来做厨房的台面 .

2009年3月13日 · 德玛拉金缎 Giallo Damara 德州粉红 Texas Pink 德州粉红(金杜鹃) Texas Red 德州红 Dallas Pink ... 罗马隆石 Sakhreh 沙利红 Sally Rosa 西摩金 Samoa 鲁班米黄 Sanam 圣 .

2025年3月22日 · 您在查找德西米兰石英石怎么样吗? 抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。 更有海量高清视频、相关直播、用户,满足您的在线观看需求。

德希米尔石英石是中国石英石行业品牌,是一家新型建筑及装饰材料研发、生产、销售、服务为一体的企业。 公司设有华北华南两个生产基地,一期占地面积24000平方米,公司重金引进六条 .

2024年5月31日 · 他们在充分继承传统赏石文化的基础上,著书立说、吹响英石前进的号角,特别是英德市英石非遗研学实践教育基地的落地,为英石文化的传承注入了新的时代活力。 英德市 .

德西米兰石英石 德西米兰石英石在线双色石英石新款_图片_价格_石英石双色板哪个牌子双色石英石网店推荐 石英石价格促销更多双色石英石欢迎广大网友为我们提供双色石英石的有关优 .

2020年8月20日 · 德西米尔石英石 还真的是挺不错的呢,这种石英石在很多厂家都有生产,并且在生产的时候会比较注重产品表面的施工和技术上的注重因此生产出来的石英石产品,符合当下 .

2006年4月27日 · 英石,广东省英德市特产,中国国家地理标志产品。英石产于英德,故又称英德石,是一种经远古地壳运动、裸露地面,经常年日晒雨淋、长期风化、自然剥落破裂而成的石 .

2010年12月6日 · 拥有杜邦人造石、杜邦蒙特利米兰石、生美人造石、奥维人造石、LG人造石、广州色丽石、天沃石英石、生美石英石、戴尔蒙德石英石、奥维石英石、华迅人造石等各种品牌 .

德西米澜石英石怎么样 展开 我来答 推荐律师服务: 若未解决您的问题,请您详细描述您的问题,通过百度律临进行免费专业咨询 为你推荐: 特别推荐 "网络厕所"会造成什么影响 ...

特性参数 非凡特性 Caesarstone 恺萨金石是自然与科技的结合。其高硬度、耐刮划、耐污渍、 设计灵感 设计灵感 Caesarstone 恺萨金石每年都会根据国际流行的色彩图案、时尚动向,向市 .