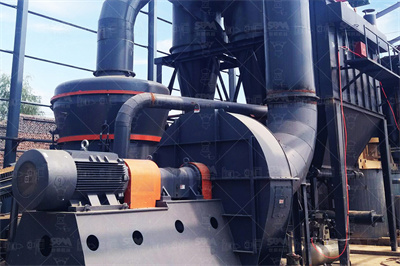

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2024年6月27日 · 一方石子多少吨怎么算?石子多少钱一吨2022价格表?石子是常见的建筑材料之一,广泛应用于各类建筑工程中。了解石子的重量和价格对于业主和工程师来说都至关重要。以下是关于一方石子的重量计算和2022年石子价格的相

由于此网站的设置,我们无法提供该页面的具体描述。

2024年5月24日 · 石头护坡一般多少钱一方1. 石头护坡的成本通常包括石料、水泥、沙子、人工和机械使用费。2. 清包情况下,每方石护坡的成本大约在50到60元人民币。3. 如果是包工包料的情况,每方石护坡的成本则在170到190元人民币。4

2015年10月21日 · 石方:其工作对象是石头,如开山、运石头等,可以人工操作,也可以机械操作或爆破。 石方爆破指的是在道路、桥梁、矿山、隧道、水利水电、场平、基坑、孔桩、管道沟等 工程施工 中,使用炸药雷管等爆破材料对土石方进行爆破,以达到开挖的目的的一种广泛应用的施 .

2020年6月10日 · 石头密度在吨/立方米到吨/立方米,1立方米石头大约在吨到吨之间,1立方米石头等于吨。 石头可以用来打火、可以美容、做食品、玉石养颜等,石头有 .

2019年10月9日 · 1立方块石等于顿左右。 石头密度为2g每 立方厘米. 一方=立方厘米. g,就是2吨. *2=吨. *2=吨. 上面是没有考虑空隙因素的。 从实际生产生活 .

2021年9月4日 · 爆破一方石头要多少钱!!!一般情况下一方石头在8到14元左右。爆破(blasting)是利用炸药在空气、水、土石介质或物体中爆炸所产生的压缩、松动、破坏、抛掷及杀伤作用,达到预期目的的一门技术。爆破这种快速现象有

2023年2月10日 · 石头,五十斤至三百斤,方在铁丝网上,用水上吊机吊到六至七米,要多少钱一吨? 您好 亲! 久等了,石头,五十斤至三百斤,方在铁丝网上,用水上吊机吊到六至七米,要85100元/吨。

由于此网站的设置,我们无法提供该页面的具体描述。

由于此网站的设置,我们无法提供该页面的具体描述。

由于此网站的设置,我们无法提供该页面的具体描述。

2022年10月4日 · 不包爆药,人工费,多少钱一个立方 1.爆破石方大抵600元立方米;2.装车大抵元立方米3.外运1千米大抵15 元立方米 钻工 你好,钻工费,爆破费,全包600元一个立方 是的 全包 亲 1.爆破石方大抵600元立方米;2.装车大抵元立方米3.外运1千米大抵15元 ...

2023年5月10日 · 汉白玉原石一立方多少钱? 1 个回答 社会民生小田 专业答主 服务有保障 关注 展开全部 摘要 您好,3000元以上,汉白玉原石一立方元。一般来说,石材材质不同,产地不同,价格不同。石材按立方米论价,目前石材市场采购价为:芝麻白 ...

2024年11月1日 · 块石多少钱一立方块石的价格因地区、品质、规格等因素而异。一般来说,块石的价格在50到300元每立方不等。以下是关于块石价格的1. 地区差异:不同地区的块石价格会有所不同。一般来说,采石场、矿山所在地附近的块石

2023年12月28日 · 一般来说,一方石头的价格加上两袋水泥(方沙),人工和机械费用,清包的话每方50-60元,而包工包料则需要170-190元。 但是,具体价格还需要根据当地的材料 .

2023年12月26日 · 您好,1立方石头的价格大概是60元一米。 举个例子,如果我们为规格为200*300*1000mm的路沿石询价,如果厂家告诉我们出厂是100元1立方,根据公式我们这样 .

2015年4月19日 · 土方工程单价多少钱一立方 862 土石方开挖,石方单价是多少钱一方? 我是全包。 122 土石方开挖多少价 4 土石方开挖单价 12 土石方工程0至3公里开挖转运多少钱一方? 2 请问目前土石方开挖,运距1公里内需要多少钱一立方 17

2024年3月30日 · 2022年石子的价格大约为40元一吨,换算下来,一方石子(约吨)的价格在96元至104元之间。 石子是广义上的称呼,包括白石子、彩色石子、黑色石子、碎石、砾石 .

2020年6月24日 · 1t大约等于,一立方碎石95元~81元。 一吨碎石大约为多少立方米? 聚苯板一立方380元/立方米,厚度30厚怎么换成一平方米多少钱? 如果一吨级配砂石 100块 那 .

2024年12月6日 · 当前市场上,一方花岗岩建筑料石的费用大约在200300元左右。 大理岩的硬度较低,易于加工和雕刻,在建筑工程和室内装修中常作为装饰材料使用。 一方大理岩建筑料石 .

2024年4月11日 · 石子一方多少钱?1. 石子价格的确定通常考虑石质的种类、运输的距离和难度、以及运输成本等因素,通常每方石子的价格在20到30元之间。2. 若要计算运费,可以使用以下公式来估算成本:每公里成本 = 吨位 * * 50

2015年10月22日 · 水利定额一平方石驳岸多少钱 混凝土打桩驳岸每平米造价 毛石护坡驳岸包工包料全包多少一立方,谢谢! 这样的驳岸墙是c20的片石砼,造价多少能干 河堤护坡造价 14 石驳岸的造价大概多少

2020年7月9日 · 6、哪位师傅知道石头砌的挡土墙造价多少钱一平方?谢谢! 可以测算一下,首先要知道主材费,用的是什么石头,普通的毛石应该在300元每立方,人工费120元每立方,综合下来,成本在500元每立方。通常我们不按米计价,因为宽度不一致

2021年5月26日 · 全是石头,需要爆破。 有18万方。 本回答被网友采纳 已赞过 已踩过 你对这个回答的评价是? 评论 ... 土方工程单价多少钱一立方 941 开挖土石方一般多少的单价 36 开挖土石方需要多少钱一立方 3 土石方开挖多少 ...

阿里巴巴为您找到94,215个今日最新的景观石价格,景观石批发价格等行情走势,您还可以找公园景观石,黑色景观石,小景观石,园林景观石,山东景观石,大型园林景观石,泰山景观石,景观石 大型,湖南景观石,石雕风景石市场价格、批发价格等相关产品的价格信息。

2021年6月16日 · 砌石头墙多少钱一立方要用水泥约33公斤,砂约立方米。 至于造价,这个主要看各个地方的材料及人工单价了,我们这里条石大约80元#47;立方米,水泥300元#47;吨,砂130元#47;立方米,泥工80元#47;工日。

2023年4月19日 · 亲,您好,石方破碎一方2440元,按照市场上破碎一吨石头的成本价差不多在1220元,那么一方石头的破碎成本就是2440元不等,还要根据当地的市场价格而定,比如购买爆破装备的费用、租赁铲车的费用(有的地区按石头多少收费,有的地区按照一小时多少钱收费)。

2023年12月25日 · 但是,由于石头是虚方,因此一方的石头实际能够使用的部分仅为到方。 接下来,我们根据墙的高度来分析工程造价。如果墙的高度分别为2米、米和3米,那么包工包料的工程造价大约是300块钱一方。

2022年7月25日 · 使用百度知道APP,立即抢鲜体验。你的手机镜头里或许有别人想知道的答案。

阿里巴巴为您找到664个今日最新的一吨石子价格,一吨石子批发价格等行情走势,您还可以找市场价格、批发价格等相关产品的价格信息。阿里巴巴也提供相关一吨石子供应商的简介,主营产品,图片,销量等全方位信息,为您订购产品提供全方位的价格参考。

阿里巴巴为您找到941个今日最新的块石价格,块石批发价格等行情走势,您还可以找块石 护坡,小块石,块石 浆砌,块石 自然,毛块石,块石 天然,花岗岩块石市场价格、批发价格等相关产品的价格信息。阿里巴巴也提供相关块石供应商的简介,主营产品,图片,销量等全方位信息,为您订购产品提供 .