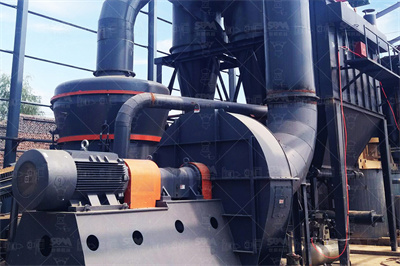

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2024年7月30日 · 3、一种基于含铁固废催化碳酸盐直接加氢分解还原的工艺,采用含铁固废为催化剂,在反应器中催化碳酸盐热解耦合供氢分子催化还原的反应,得到包含金属氧化物的固体产物和包含一氧化碳的气体产物;所述含铁固废为选自赤泥、钢渣、粉煤灰、煤矸石中的一

2021年2月19日 · 煤矸石 煤矸石来源及组成煤矸石是矿业固体废物的一种,是洗煤厂的洗矸、煤炭生产中的手选矸、半煤巷和岩巷掘进中排出的煤和岩石以及和煤矸石一起堆放的煤系之外的白矸等的混合物。

2005年9月12日 · 利用煤矸石为原料生产的建材产品,产品质量应符合国家或行业标准;对用于生产建材产品的煤矸石应进行放射性测量,原料符合GB9196-88标准,制品中放射性元素含量 .

2025年2月27日 · 年产10万m3煤矸石混凝土砌块的生产工艺设计 摘要 本设计的题目为年产10万立方米的煤矸石混凝土砌块的生产工艺设计。首先得对煤矸石的组成、应用以及优缺点进行概述,再次要熟练混凝土配合比的计算和煤矸石掺量,而且自行设计砌块块型,以达到保温节能的要求。

2018年3月12日 · 学术争鸣96017年11月30学术争鸣煤矸石混合料生产水泥工艺研究陈晨河北唐山063000摘要:煤矸石是采煤与洗煤过程中排放的固体废物,是成煤过程中与煤层伴生的一种含碳量低、坚硬的黑色岩石。自改革开放以来,为推动经济快速发展,我国对煤矿的开采力度非常大,然而,与西方国家相比,我国煤炭 ...

日本利用筑丰煤田的部分高岭石含量高的煤矸石生产耐火材料,以"矸石耐火粘土砖"的商品名称出售,据日本的研究,用淘析法和盐酸进行处理,可大幅度提高煤矸石的耐火度,此外日本还用煤矸石作路基材料铺了几段数百米的公路进行试验,试验取得良好成果。

2021年9月22日 · 曾经饱受嫌弃的煤矸石,从此扬眉吐气。 "以王洼煤业公司开采煤炭产生的固废煤矸石为原料,生产、销售的新型环保空心砖、多孔砖等环保节能型墙体建筑材料,已完全打开了市场。"经历各种挑战后,李会标愈加坦然。

2020年2月28日 · 5)利用煤矸石配料生产硅酸盐水泥熟料方案,不仅消耗了大量的固体废弃物煤矸石,同时消耗了大量工业废弃物如河道淤沙、转炉渣等,减少废渣的堆放,有利于美化生态环境。附图说明 图1是本发明中一种煤矸石生产硅酸盐水泥熟料的制备方法的工艺流程图。

用作水 泥混合材的煤矸石要求是炭质泥岩和泥岩、砂岩、石灰岩(氧化钙含量>70%), 通常选用过火或煅烧过的煤矸石。 煤矸石的活性应符合 GBl2957-92 标准,放射 性应符合 .

煤矸石是煤矿生产过程中产生的废弃物。长期以来,煤矸石的大量堆存,给矿区生态环境带来种种负面影响,不仅占用土地、污染环境,而且破坏景观。但实际上煤矸石并不是一种简单的废弃物,而是可利用的资源。随着科技的发展,煤矸石的用途逐渐被认识。

该领域下的技术专家 如您需求助技术专家,请点此查看客服电话进行咨询。 1、张老师:1.探索新型氧化还原酶结构功能关系,电催化反应机制 2.酶电催化导向的酶分子改造 3.纳米材料、生物功能多肽对酶电极体系的影响4.生物电化学传感和生物电合成体系的设计与应用。

由于此网站的设置,我们无法提供该页面的具体描述。

2019年5月3日 · 其次虽有以煤矸石为原料生产钛白粉的 少量报道,但是其对钛与其他杂质分离提纯的效率仍然存在很大的改进空间 ... 其中氧化钙与煤矸石质量比为:1,浸出过程液固比为质量比,浸出温度为4060℃,浸出时间为2h,sio2的浸出率为%。

煤矸石是与煤系地层共生、由多种矿岩组成的混合物,以层 状结构的硅酸盐黏土矿物和石英为主,是煤炭开采过程中的废 弃物。 这些废弃物大量露天堆积,日晒雨淋,对周围环境和人体 都 .

由于此网站的设置,我们无法提供该页面的具体描述。

2010年8月17日 · 近年来,许多国 家都在研究和发展将煤矸石应用于水泥工业的新工艺技 术。 一、煤矸石作原燃料生产水泥 以煤矸石作为原燃料生产水泥,主要是根据煤矸石和 粘土的化学成分相近,可代替粘土提供硅铝质原料,再加 上煤矸石能释放一定的热量,可节省部分的 ...

洗煤是煤炭深加工的一个不可缺少的工序,从矿井中直接开采出来的煤炭叫 原煤,原煤在开采过程中混入了许多杂质,而且煤炭的品质也不同,内在灰分 小和内在灰分大的煤混杂在一起。 洗煤就是将原煤中的杂质剔除,或将优质煤和劣质煤炭进行分门别类的一种工业工艺 [2]。

煤矸石中加入一定量的石灰石,高温下煅烧,使高岭石转化为硅酸二钙(C2S)和七铝十二钙(C12A7)。 煅烧后产物为块状烧结物,利用硅酸二钙晶相转化过程中产生的体积膨胀(处于 .

2022年3月1日 · 1、浅析煤矸石制水泥工艺与效果水泥的化学成分对其性能有决定影响,由于煤矸石化学成分和工艺性能复杂,生产上难于控制,造成生料化学成分的不稳定,煅烧操作稳定底火困难,窑内经常出现不正常窑况,热工制度紊乱,导致立窑煅烧质量降低。

![国经贸资源[1999]1005号 国家经贸委 科技部关于印发《煤 ...](/bzn2vgy/53.jpg)

1999年10月20日 · 如果煤矸石的岩石组成以砂岩和石灰岩为主,在进行回填时,累加入适量的粘土、粉煤灰或水泥等胶结材料,以增加充填料的粘结性和惰性;当煤矸石的岩石组成以泥岩和炭质泥岩为主时,则需加入适量的砂子,以增加充填料的骨架结构和惰性。

2020年3月10日 · 摘要:以煤矸石为原料,经过高温焙烧、酸浸、聚合、熟化等过程制备了高效无机高分子絮凝剂聚合氯化铝铁钙(PAFCC),通过单因素试验研究了PAFCC制备条件对浊度、COD和UV 254 去除率的影响。 试验结果表明,PAFCC最佳聚合条件为pH值2 ...

2023年8月9日 · 全煤矸石烧结空心砖生产技术及装备 技术装备简介:对煤矸石破碎及陈化处理,再经真空挤出机挤出成型,由切条机及切坯机切割成需要的砖型,再经干燥、焙烧等工艺制备空心砖。关键技术:全煤矸石烧结技术;伺服控制技术。

2014年12月22日 · 利用煤矸石全部或部分代替粘土,采用适当烧制工艺生产烧结砖的技术在我国已经成熟,这是大宗利用煤矸石的主要途径。生产烧结砖对煤矸石原料的化学组成要求:二氧化硅为55~70%,三氧化二铝为15~25%,三氧化二铁为2~8%,氧化钙≤2%,氧化镁≤

2001年1月31日 · 。本发明涉及利用铝硅酸盐矿物(煤矸石、粘土、高岭土、铝土矿、黄砂、粉煤灰)的化工开发利用的方法,特别是利用煤矸石的生产铝盐和硅酸盐工艺方法。据冯诗庆于1995年第4期《无机盐工业》杂志第2224页刊文《煤矸石制铝盐和白炭黑》(对比文献1)中称截止1991年底,我国煤矸石的排出量已达22亿吨 ...

2021年12月15日 · 与国内相比国外对煤矸石的综合利用较早,70年代初,德国法国等国的煤矸石综合利用率已达3050其中一些国家部分矿区的煤矸石 ... 煤矸石生产建筑材料目前国家已经命令禁止利用粘土烧制粘土砖, 煤矸石烧制砖的工艺比粘土制 砖工艺增加 了一 ...

氢氧化钙生产线工艺流程:. 将合格的氧化钙(CaO)块料由鄂式破碎机破碎40mm左右粒度,经斗式提升机送入氧化钙储存罐料仓,料仓中的氧化钙经稳流输送机定量 徐州石灰厂家解析碳酸钙 .