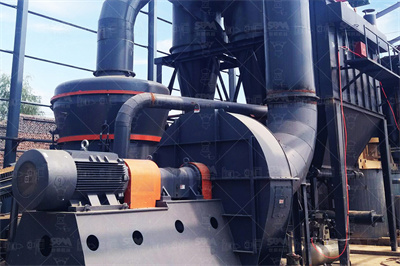

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2022年4月19日 · 山东长岛月牙湾在哪里?山东省烟台市长岛县北长山岛西北角(从码头去九丈崖的路上),长岛半月湾球石,一次旅行,我只能为你捡一颗石子,让石子的颜色和形状、捡石子的心情和海滩深浅代替我,来跟你细数关于这个世界不同的美好。

2017年7月4日 · 长岛月牙湾景点 又称半月湾,景区坐落于长岛县北长山岛最北端,自然形成长约2000米的月牙长滩,因湾形似半月而得名。 它背依青山绿野,环抱碧海清波,一袭银白球石 .

2024年9月19日 · 中新网烟台9月18日电 题:山东这座宝藏海岛探"绿"有方 中新网记者 杨兵 王娇妮 位于山东省东北部的长山列岛仿佛镶嵌在黄渤海间的明珠项链,九丈崖、月牙湾等一处处被海浪"雕刻"过的景观令人惊艳。

由于此网站的设置,我们无法提供该页面的具体描述。

2024年7月19日 · 九丈崖就在月牙湾旁边,可以坐景区的车过去,每人20元,可以看看沿途风景,想省钱就出门打车,15块钱,送到九丈崖门口。 长岛景区可以使用人脸识别的,买联票后,进过一个景区,其余景区刷脸就可以了,但小孩不行。

2021年4月22日 · 月牙湾,位于山东省烟台市蓬莱区长岛县北长山岛嵩前村北端。是一条自然形成的长约2000米的月牙形海滩,因湾形似半月而得名。西依珍珠门水道,北邻国际航道长山水道,是集山、海、岛、礁、崖、滩、洞、古迹于一体的景观。二十世纪八十年代,半月湾以月牙湾的大名迅速成为长岛旅游的景点 ...

2021年4月22日 · 西依珍珠门水道,北邻国际航道长山水道,是集山、海、岛、礁、崖、滩、洞、古迹于一体的景观。二十世纪八十年代,半月湾以月牙湾的大名迅速成为长岛旅游的景点之 .

由于此网站的设置,我们无法提供该页面的具体描述。

2023年4月11日 · 穷游网为广大穷游er提供月牙湾地质公园旅游攻略,门票、简介、地址、电话、网址、交通线路、开放时间、周边信息,网友点评等,为穷游er制订月牙湾地质公园出游计划提供参考。

2024年10月17日 · 月牙湾又称半月湾,坐落于长岛县北长山岛最北端,自然形成长约2000米的月牙长滩,因湾形似半月而得名。 它背依青山绿野,环抱碧海清波,一袭银白球石的遥遥长滩,镶 .

2017年11月26日 · 长岛的月牙湾到了长岛以后你可以打车到月牙湾,打车应该是不出20元,你最好是打上表那样是比较准的,九丈崖和月牙湾必须的一起买的,一买就是两个景点。月牙湾的球石是不准捡的,因为球石的资源越来越少了,为了能让

由于此网站的设置,我们无法提供该页面的具体描述。

2023年12月22日 · 坐落于烟台长岛县北长山岛最北端的月牙湾,以其半月形的长滩而闻名,真是个绝美的地方! 别担心,我会给你介绍得更详细一些。 月牙湾之旅 ...

由于此网站的设置,我们无法提供该页面的具体描述。

2024年12月26日 · 月牙湾又称半月湾,坐落于长岛县北长山岛最北端,自然形成长约2000米的月牙长滩,因湾形似半月而得名。它背依青山绿野,环抱碧海清波,一袭银白球石的遥遥长滩,镶嵌在青山碧水之间,犹如深邃夜空中的一弯新月。同名歌曲《月牙湾》,取材自敦煌月牙泉(即月牙湾),月牙泉因为形状酷似 ...

2015年4月28日 · "九丈崖"与"月牙湾"近在咫尺,乘车只需5分钟的时间。"月牙湾"又称"半月湾",这两个名字与两位老帅有着一段情缘。1955年国防部长彭德怀视察长岛要塞,与高炮阵地侧畔, .

2016年9月3日 · 到长岛给人脑海留下的最深的是月牙湾的五彩卵石,长岛人叫球石,可与南京的雨花石媲美,这种卵石,质地坚硬,光洁圆润花斑图岸精美,{我 ...

由于此网站的设置,我们无法提供该页面的具体描述。

2019年10月30日 · 坐落于长岛县北长山岛最北端的月牙湾,因海湾形似一弯新月而得名,是一处自然形成的天然海水浴场。这些一亿多年前造山运动时从海底抬升的沉积岩,在浪花、海流的侵蚀下,崖壁斜探海中,崖底的石柱、石穴等海蚀地貌一览无余,.

去哪儿攻略旅游攻略,自由行,自助游攻略,旅游社交分享网站

2024年2月11日 · 月牙湾位于长岛的东北部,距离县城较远,建议早点出发。 在月牙湾,你可以沿着海滩散步,欣赏弧形的海岸线和清澈的海水。 还可以选择登上观景台,俯瞰整个海湾的美景 .

2016年9月3日 · 房东说在月牙湾还没有收门票时月牙湾的球石多到堆积到现在的大堤上,现在为什么这么少了,因为在几十年前,人们在实践中发现球石在2000度的 ...