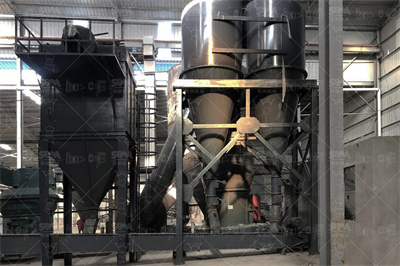

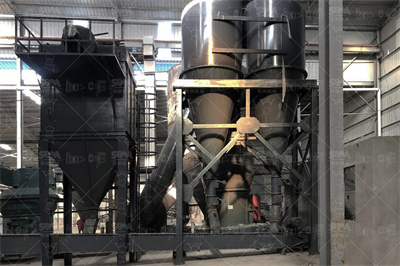

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2017年8月10日 · 粉碎机负荷单片机智能控制系统.doc,粉碎机负荷单片机智能控制系统 陈学永1 沈美雄2 (1福建农林大学机电学院,福州350002 2福建省机械科学研究院,福州350005) 摘要: 本文从分析超微粉碎机负荷与能耗和粉碎作业质量的关系,指出粉碎机负荷控制 ...

2021年9月14日 · 主要的一个原因就是由于粉碎量过大导致超负荷的工作,然后粉碎机出现跳闸。 粉碎机不开控制系统不会出现跳闸的现象,一开就出现跳闸的现象,首先出现跳闸的原因就是因为短路而引起,粉碎机不开或者是不跳闸,但是当我们在进行使用的时候就会

2022年4月28日 · 用户在使用超微粉碎机的时候,都会遇到开关打开没一会就跳闸的问题,这对于需要紧急粉碎的物料来说的确是一个让人头疼的事情。 那么,粉碎机总跳闸怎么办呢,下面让超微粉碎机厂家来分析一下出现原因及解决方法。

2014年12月6日 · 粉碎机开关一开会跳闸是怎么回事你好,粉碎机一开就跳闸,一开关容量选择过小,或者开关使用时间过长,自身原因不稳定,引起的误动作。二是开关负载侧线路绝缘损坏,负载接地短路都会引起开关跳闸。

2020年5月19日 · 铡草粉碎机用一会就家里就跳闸怎么办?那就证明你的空开太小啦!可是你的电机太大,超负荷 工作当然会掉哪呀?对呀,换一个大点的空开就没问题啦。我可以是一世。 百度首页 商城 注册 登录 网页 资讯 视频 图片 知道 文库 贴吧 采购 地图 ...

2015年3月28日 · 1、机械部分卡住(粉碎机槽内有异物) 2、离心器没有打开 3、电源电压过低 1、 清除粉碎槽内异物,开机先空转半分钟后再慢慢喂料 2、调正电源电压 电机机壳表面过热 1、 .

4、粉碎机起动后应先空转2~3min,没有异常现象后再投料工作.1。5、工作中要随时注意粉碎机的运转情况,送料要均匀,以防阻塞闷车,不要长时间超负荷工作.若发现有振动、杂音、轴承与机体温度过高,向外喷料等现象,

2018年11月21日 · 、由于本机电机功率为,电流量较大,万一开机瞬间产生线路跳闸,请更换到负荷比较大 ... FDV超微粉碎机 文件名称 FDV超微粉碎机使用、维护、保养标准操作规程 文件编号 编 制 人 编制日期 年 月 日 生效日期 年 月 日 审 核 人 审核日期 ...

解决 办法 : 及 时停下检查, 消除 障碍, 否则很有可能烧坏 电机 。 粉碎机转子 和电机转子不 同心时 .. 容易振动 .. 可左右 移动电机, 使 2 . 2绕组 问题 粉碎机转子和电机转子 同心 .

冲击破广泛应用于各种金属和非金属矿、水泥、耐火材料、磨料、玻璃原料、建筑骨料,机制砂、冶金等行业。适用中细碎不同硬度的各种矿石和岩石,如铁矿石、有色金属矿石、金刚砂、铝矾土、石英砂、棕刚玉、珍珠岩、玄武岩 等高硬度物料的中细碎作业,是国内外建筑、矿山、冶金行业 .

在废旧模板粉碎机使用的过程中电路部分出现跳闸是那些因素引起的?废旧模板粉碎机断路器假设处于未断开状态,先拉负荷侧隔家用粉碎机整机空载跳闸为什么常见问题塑料粉碎机电机无法启动电机不转动塑料粉碎机电机无法启动电机不转动塑料粉碎机电机无法

阿里巴巴为您找到1581条关于11kw粉碎机生产商的工商注册年份、员工人数、年营业额、信用记录、主营产品、相关11kw 粉碎机产品的供求信息、交易记录等企业详情。 查看所有类目 年营业额 100万以下元/年 101万200万元/年 301万500万元/年 500万1000万 ...

2019年11月7日 · 3、手指仪表并口述:运行时仪表灵活可靠,油位在油位线上,额定工作状态电流为200A,无超负荷 ... 5、粉碎机 防护罩完好,粉碎煤样时,压紧煤钵,盖好防护罩,粉碎机不完全停止运转不得开罩 ...

粉碎机不开不跳闸,但一开就跳闸说明短路是由于粉碎机开机后振动引起。 所以这种故障极可能是因为门保护或正反转行程开关线破皮或接线松动,因开机振动引起短路产生控制系统的跳闸。

在大曲粉碎机发生跳闸并诊断出相关原因后客户应当对照以上原因进行解决。如因设备负载过大造成的跳闸在确定原因后再次开机后应当调整上料速度降低主轴负载如大曲粉找引起发电机逆功率跳闸的原因,发电机,挖掘机发动机发电机不发电的原因,小松挖掘机 供应明显效果石英石粉碎机引起行 .

2016年7月1日 · 1、粉碎机 不开控制系统不跳闸,一开就跳闸。 首先,跳闸是因为短路而引起。粉碎机 不开不跳闸,但一开就跳闸说明短路是由于 粉碎机 开机后振动引起。 所以这种故障极可能是因为门保护或正反转行程开关线破皮或接线松动,因开机振动引起短路产生控制系统的跳闸。

2015年11月21日 · 11kw三相电机配几大的空气开关11KW的电机用40的空开就可以,用80的还跳闸说明电机有故障或着检查线路。空开一般起到短路保护作用,偶尔过载不能保护跳闸的,既然电机能正常运行,说明没问题,你换一个空开吧,它的电

2016年11月2日 · 一台粉碎机11kw(4P)电机有多少转速 我该用多大的电机粉碎机是11KW(4P)也就是粉碎机需要输入的功率是 ... 但也不是绝对的,这里存在一个过负荷的问题,如果过负荷使用,很短的时间应该允许,但是时间长时则电动机可能被长时间过载 ...

2021年5月31日 · 如果厨余粉碎机一点动静都没有的话,有可能是电源出问题了,首先检查洗碗槽下方的插头,再检查house地下室的开关控制盒,看厨余粉碎机对应的开关是否有跳闸。 2. 试试重置超载按钮 如果电机超负荷工作,可能导致停止工作。

2023年11月25日 · 万能粉碎机堵塞是粉碎机使用中常见的故障之一,可能有机具设计上存在的问题,但更多是由于使用操作不当造成的。 1、进料速度过快,负荷增大,造成堵塞。 在进料过程 .