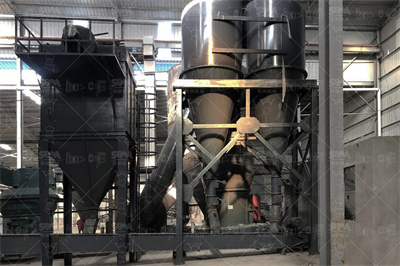

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

售后保障及服务团队 公司多次获得优秀企业奖,并多次被评为重合同守信用,售后服务先进单位,是冶金行业选矿机械的骨干企业,公司产品多年来畅销全国各地,尤其是重选设备远销东南亚各国。

2022年11月13日 · 这里是江西兴业机械设备有限公司在顺企网赣州黄页的介绍页,位于江西省赣州市石城县琴江镇温坊工业园,营业范围有矿山机械、实验室选矿制样设备、仪器仪表、电子产品、机电设备、建筑工程机械销售、维修、技术服务及对外贸易*,联系电话为:

潍坊永晨沙矿机械生产的沙金选矿设备,由专业工程师量身打造,可适应各类复杂地形.永晨沙金选矿设备,性能稳定,环保科学,能耗低..

石城县华贸选矿设备厂最新产品 查看更多 CP3600磁选机 三盘电磁磁选机 钨锡矿磁选机 稀土.. 山西大同单槽浮选机实验浮选机|浮选机 山西太原磁选机湿法鼓式磁选机|实验磁选管|棍式.. 山西太原震动磨样机制样粉碎机,矿样粉碎研磨机

受业主委托,中国采招网于2024年12月18日发布四川会理铅锌股份有限公司选矿实验设备采购项目网络竞价公告; 项目简介: 四川会理铅锌股份有限公司 选矿实验设备 采购项目采购公告 四川会理铅锌股份有限公司委托凉山西南联交所企业服务有限 ...

2025年1月26日 · 石城县金川选矿设备制造有限公司是选矿设备,矿山设备等系产品专业生产加工的公司,主要制造的产品有选矿设备和矿业实验化验设备等机械产品,另可根据客户要求定做 .

超详细选矿设备列表,鑫海为您提供选矿各流程的选矿设备,包括但不限于球磨机、浮选机、浓缩机、解吸电解设备。 品类齐全,总有一款适合您。 电子邮箱 xrguo

选矿设备和 选矿工艺 的发展是同步的,工艺 是主导,设备是基础。 一种新型选矿设备的诞生,往往带来选矿工艺的变革。设备的技术水平不仅是工艺水平的前提,也直接影响着生产过程的畅通和应用。科学技术的进步,各科学门类间相互渗透和各行业间的相互融合,新结构、新材质、新技术 .

磨矿设备是矿物加工(选矿)工程中的准备作业—磨矿工艺的关键设备。 磨矿工艺的研究是 矿物加工工程 技术中的重点之一。 碎磨工艺是利用能量对矿石进行 挤压、 冲击 和 研磨,使矿石中有用矿物单体解理,利于下阶段进行选别的过程。目前,大中型选矿厂的碎磨工艺中(粗碎除外)作 .

鑫海一直致力于为客户提供更专业的选厂整体服务,从选矿咨询、选矿试验到选厂设计、选矿设备生产,再到选厂设备安装及调试,最终实现达标达产,一共完成了500多个金属、非金属选矿项目,从不断完善优化自己的服务,到形成自己一套服务体系,鑫海真正

江西省石城县永盛选矿设备厂坐落于中国着名的"白莲之乡"—石城,永盛企业始建于上世纪八十年代,是一家从事矿物成分分析,选矿实验服务,矿山机械制造,选矿设备选型,设备安装调,技术培训于一体的专业机构。

江西石城县永盛选矿设备制造有限公司主营产品有洗砂机、洗沙设备、砂石筛分、山砂设备、矿山设备、选矿设备、筛分设备、螺旋溜槽、垃圾分选设备、盾构土再生设备等。公司在近30年的创业经历中,积累了丰富的实践经验,现已发展成为占地13000多平方米,生产车间5000平方米的现代 .

2017年3月9日 · 实验室选矿设备:主要产品有实验室用各种充气式单槽、挂槽、多功能浮选机、微型闭路连续浮选机、环射式连续浮选机、机械搅拌式连续浮选机、微量加药泵、浓度计、实验室高温高压常温常压高温常压解析 — 电解装置、实验室堆浸锌丝置换装置、实验室

这里是石城县南方有色选矿设备厂在顺企网赣州黄页的介绍页,位于县工业园桥头南端,营业范围有 ... 石城县南方有色选矿设备厂是江西省的一个老牌选矿设备制造企业,是一家集选矿试验、矿山设计、机械制造、安装调试、人员培训一体的现代化综合 ...

石城县宏兴选矿设备厂 江西 赣州 免费选矿技术指导、选矿实验、选矿流程设计 品牌:锯齿波梯形跳汰机 ... 主营产品: 选矿实验研究,采选工程咨询设计,选冶设备制造安装及大修,井下无轨设备制造及大修、井巷工程施工建设、矿...

对矿样进行分析、根据矿样提供合理优化的选矿实验、选矿流程设计、设备选型、设备安装调试于一体的大型矿业服务机构。 它坐落在江西省赣州市石城县——素有"闽粤通衢"之称,是海西经 .

江西石城县南方有色选矿设备制造有限公司是6S、云锡摇床、玻璃钢摇床、跳汰机、螺旋分级机、搅拌桶、节能球磨机、破碎机、振动筛、螺旋溜槽、给矿机、磁选机、砂泵、实验设备、输送机、水力分级机、旋流器等产品生产加工的私营有限责任公司

2025年1月19日 · 可以为用户提供厂址选址、选矿试验、设备选型、工艺流程设计、设备采购及安装的EPC ... 室、人力资源部、安全部、财务部、审计部、办公室、监理中心、工程建设安装公司、无轨设备厂、矿山机械厂、设计院、营销公司等,是一家历史悠 2

选矿设备是一种干式分选设备,可以替代传统的水摇床,不用水,环保,分选精度高.

(三)无轨设备厂是地下无轨铲运设备专业制造厂,有着30多年地下无轨设备维修、生产制造经验,具备6立方米以下铲运机和35 ... 选矿实验 研究,采选工程咨询设计,选冶设备制造安装及大修,井下无轨设备制造及大修、井巷工程施工建设、矿山工程 ...

本公司是一家专业从事矿山机械制造,矿物分析,选矿试验,流程设计、设备选型、安装调试及进出口业务为一体的大型矿业服务机构,是冶金行业选矿机械的骨干企业。

以上是顺企网赣州石城县黄页企业单位名录,有包括赣州富邦冶金机械有限公司、石城县浩鑫矿山机械制造厂、江西省恒城选矿设备有限公司、江西龙达矿山机械制造有限公司等在内的30422家赣州石城县厂家、赣州石城县供应商批发商的介绍和地址电话法人代表和联系电话等信息,一共分 .

选矿机免费获取报价;青州金启矿机承接各种型号的淘金设备定制,业务覆盖国内外;精益技术赢得客户好评;可邀客户进厂考察诚信招待.

2021年1月4日 · 金矿选矿 设备 Mineral processing equipment for gold ore №L1 M 浓缩机 Thickeners №M1 N 过滤机、烘干机、离心脱水机 ... 试验 室岩芯切割机 Laboratory core cutting machine №1 S2 新型自动岩芯切割机 New Semiautomatic core cutting machine ...

选矿试验设备_厂家供应选矿试验设备、XJT型浸出搅拌机 厂家供应选矿试验设备、XJT型浸出搅拌机收藏产品 手机下单 用客户端扫...一、XJTII浸出搅拌机用途和简介实验室用充气多功能浸出搅拌机可供地质、冶金、...

宁德选矿设备制造厂公司主要从事矿用运输和装卸设备制作,专业生产矿用防爆机车,防爆柴油机车,矿用防爆柴油机车,防爆机车,矿公司主要产品有矿用矿用防爆机车、防爆柴油机车、防爆机车、矿用机车、矿用防爆柴油机车、牵引机车、液力变速郑州泰达矿冶设备有限公司是一家进出口 .

2022年5月30日 · 临朐泉盛电磁设备厂是集开发、工程设计、生产安装、调试服务于一体的矿山设备制造企业。主导产品有陶瓷过滤机、盘式过滤机、磁选机、干选机、电磁振动给料机、高频电磁振网筛、电磁永磁除铁器等设备。

石城县宏远选矿设备厂 江西省石城县宏远选矿设备厂(*)是地区矿山机械行业大型骨干企业之一我厂**生 产6S摇床、实验摇床、云锡摇床,玻璃钢螺旋溜槽,破碎机,*节能球磨机、螺 旋分级 .

金矿选矿设备厂,山东鑫海矿装,矿山工程施工总承包壹级资质,具备工程设计资质,对外承包工程资格,为全球矿山提供一站式,定制化选厂解决方案.欢迎致电咨询详情

吉林省吉探机械有限公司(原 吉林省探矿机械厂 ) 隶属于吉林省地质矿产勘查开发局,始建于1958年,座落于长春市高新区超越大街1188号。 本厂产品主要分为实验室选矿仪器及设备;矿山选冶设备。生产历史悠久,技术力量雄厚,形成科研、设计、新产品开发、生产、制造一体化的专 .

2021年9月16日 · 石城县益石矿山设备有限公司位于石城县工业园古樟园区,是一家专业从事矿山机械、选矿设备、筛分设备、洗矿设备的生产制造商,主要产品有: 球磨机、螺旋分级机、洗矿机、滚筒筛、振动筛、选矿摇床、螺旋溜槽、跳汰机、离心选矿机等,各类产品型号齐全,还可以根据客户需求量身定制。

2024年7月4日 · 山东鑫海矿业技术装备股份有限公司提供专业的选矿总包服务,高效节能球磨机,浮选机,浓缩机等选矿设备,优质选矿生产线,选矿工艺.欢迎咨询: 电子邮箱 .

2022年6月7日 · 石城县赣冶选矿设备厂是冶金行业选矿设备的生产企业。 可为用户提供项目设计,工艺流程设计,标准和非标准产品设计及生产。

选矿厂设计包括选矿与冶炼两部分,选矿最终产品为金品位大于90%的金锭。该选矿厂为炭浸法提金系统,包括破碎、磨矿、炭浸、冶炼、尾渣与回水等基本生产系统。 > 更多