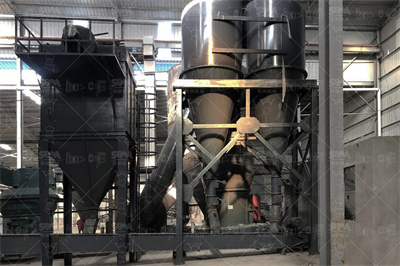

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2022年8月19日 · 在新一轮规划中,宁夏将结合实际,把主要矿种找矿突破、矿山节约化规模化程度提升、矿业转型升级绿色发展、矿产资源管理水平提高作为"十四五"矿产资源管理的主要规 .

2024年2月25日 · 宁夏煤炭及非金属建材矿产资源遍布全区,具有量大质优的特点;金属矿产资源主要分布在卫宁北山及香山地区,呈规模小品质差的特点;煤、石膏、石灰岩、硅石、镁矿、 .

2022年10月20日 · 进绿色矿山建设,制定宁夏煤矿、非金属矿、砂石土矿、水泥 用灰岩矿绿色矿山建设规范,从矿区环境、资源开采方式等方 面为自治区绿色矿山建设提供科学依据。

2018年10月18日 · 推动形成节能锅炉、脱硫脱硝除尘设备、节能环保监测设备、工业废弃物综合利用、矿产资源综合利用、环境修复六大产业集群;培育35家环保设备龙头企业,12个资源利 .

2017年3月9日 · 宁夏石膏矿藏探明探明储量45亿吨以上,居全国首位,品质较好,其中一级品占储量的一半以上。 90%以上资源储量分布在盐池县、同心县与固原市原州区古近纪盆地和中卫市 .

由于此网站的设置,我们无法提供该页面的具体描述。

2023年5月15日 · 今天的宁东,成为宁夏经济发展的重要引擎,产值近2000亿元的化工园区、国家产业转型升级示范区和现代煤化工产业示范区。2003年,宁夏决定举全区之力建设宁东能源化工基地,并将其确立为自治区"一号工程"。

2017年3月10日 · 宁夏地区矿藏资源储量以煤为主,次为建材非金属矿产,金属矿产贫乏,其中非金属矿资源主要有石膏、石英砂岩、黏土矿物、白云岩、膨润土、磷、铸型用砂、硫铁矿、铸石原料等。

2024年4月1日 · 摘要: 这是一篇矿业工程领域的论文.矿产资源是经济社会发展的重要物质基础,摸清矿产资源家底,掌握矿产资源开发利用状况,对科学制定资源战略规划和政策,守住矿产资源安 .

2018年11月12日 · 铁矿石制粉生产线的具体流程怎么样 发布日期: 浏览次数: 文章来源:佰辰机械 导读: 铁矿粉的来源就是铁矿石,自然界中铁矿石多以伴生状态出现,因此需要经过破碎、磨矿、选矿等一系列流程后,能得到满足市场需求的铁矿粉。 矿石磨粉机设备是铁矿石细磨,直至磨成细粉

粉末冶金包括制粉和制品。其中制粉主要是冶金过程,和字面吻合。而 粉末冶金制品 则常远远超出材料和冶金的范畴,往往是跨多学科(材料和冶金,机械和力学等)的技术。 尤其现代金属粉末 3D打印,集机械工程、CAD、逆向工程技术、分层制造技术、数控技术、材料科学、激光技术于一 .

2022年4月21日 · 宁夏建龙高炉矿渣粉项目的投产,对提高该公司固废资源利用水平、延伸产业链条、实现企业高质量发展具有重要意义,标志着宁夏建龙在实现绿色发展、减污降碳的转型升 .

2025年4月16日 · 宁夏政务服务网为公众提供便捷的政府信息公开、政务服务和互动交流功能。

2023年7月29日 · 根据宁夏回族自治区工业和信息化厅官网发布的信息显示。 1、宁夏建龙高炉矿渣粉项目的投产,2021年6月29日开工,建设工期295天。 项目主体设备采用原唐山建龙炼钢 .

2021年7月26日 · 就是在这样艰难的环境下,1962年新年,一个具有9个可采区、设计能力为216万吨的石嘴山矿区终于建成了,这就是一矿。 后来二矿、三矿、四矿,宁煤建设者们艰苦奋斗,用血汗甚至生命建起了一座座矿山,奠定了宁煤发展的根基。

2005年7月13日 · 宁夏天地西北煤机有限公司(原西北煤矿机械二厂)是中国煤炭科工集团下属的天地科技股份有限公司的控股子公司,是国家煤炭工业采掘工作面带式输送机定点生产商,企业经过四十年的发展已成为国内最大的煤矿用带式输送机生产企业。

由于此网站的设置,我们无法提供该页面的具体描述。

2022年12月19日 · 《宁夏回族自治区国民经济和社会发展第十四个五年规划 和2035年远景目标纲要》等,编制《宁夏回族自治区矿产 资源总体规划(年)》(以下简称《规划》)。

最广泛应用的是气雾化和水雾化法。雾化制粉时先用电炉或感应炉将金属原料熔炼为成分合格的合金液体(一般过热100~150℃),然后将其注入位于 雾化喷嘴 之上的中间包内。 合金液由中间包底部漏眼流出,通过喷嘴时与高速气流或水流相遇被雾化为细小液滴,雾化液滴在封闭的雾化筒内快 .