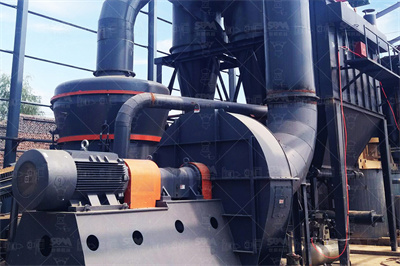

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2024年7月31日 · NOTTER压片工具的超凡品质对于多头和制粒工具来说尤为重要。 NOTTER精密工具始终以最高质量标准为目标,性能堪称完美。 凭借稳定的工作长度和精确的压制尺寸,即 .

在这些制粉工具的件数有10件及以下、11件(含)20件(含)、21件(含)30件(含)、31件(含)40件(含)和41件(含)50件(含)等多种,在制粉工具的材质有铬钒合金钢、高碳钢、碳钢、铬钼合金钢和铸 .

2012年10月23日 · 交底内容 交底内容:制粉、送粉安装项目概述及工作量;编制依据的图纸、文件和标准;作业必备条件和上道工序确认;制粉、送粉安装的顺序、方法及要求;安装过程对质量控制点的设置;制粉、送粉安装结束的检查验收和应达到的质量标准;

2021年5月27日 · 超声雾化法作为一种新型的雾化技术,通过与超声工具头 直接或间接接触的方式,将超声波的能量传递给待雾化液体并进行破碎。这种制粉技术能够得到球形度较好且粒度分布较窄的球形金属粉末,同时还具有设备和工艺简单、可控性高、成本低 ...

本发明涉及燃煤锅炉(尤其是大型电站锅炉)性能监督和检测的技术领域,具体涉及入炉煤采样系统及使用方法。背景技术对于火力发电企业来说,煤炭作为大型电站锅炉的主要燃料,燃料成本占其总运行成本的85%以上,要准确核算燃料成本必须要求对入炉煤进行准确取样,尤其是进行锅炉性 .

2015年9月1日 · 煤粉在密封的制粉设备中输送,它的特点是颗粒小、干燥、易燃,并有一定的流动性,由于在运行中泄漏及检修时散落,所以在制粉设备附近及空间一般都有煤粉存在。如在制粉设备附近动火,极有可能引起周围煤粉和制粉系统着火及爆炸事故。

2021年7月27日 · 一种超声波制粉设备工具头,包括导震接头、密封层和出液口,其特征在于所述密封层上端与导震接头相连,所述出液口设置在密封层下端,所述导震接头、密封层和出液口 .

粉末冶金包括制粉和制品。其中制粉主要是冶金过程,和字面吻合。而 粉末冶金制品 则常远远超出材料和冶金的范畴,往往是跨多学科(材料和冶金,机械和力学等)的技术。 尤其现代金属粉末 3D打印,集机械工程、CAD、逆向工程技术、分层制造技术、数控技术、材料科学、激光技术于一 .

2023年7月7日 · 超声雾化是作为一种新型的雾化技术,通过与超声工具头直接接触的方式,将超声波的能量传递给待雾化液体并进行破碎。这种制粉技术能够得到 球形度 较好且粒度分布较窄的球形金属粉末,同时还具有设备和工艺简单、可控性高、成本低的显著优势。 ...

搜狗搜索是全球首个第三代互动式中文搜索引擎,提供多种内容服务,包括网页、图片、视频、知识、问答、新闻、地图等。

2023年2月1日 · 可调开孔器利用这一刀具,仅需一个钻头即可加工出各种不同大小尺寸的孔。 双刃型 · 作业时的平衡性. 木工钻头这是用于木材的钻孔工具。 优点· 顶端具有圆锥形螺纹(前段螺 .

2017年9月29日 · 当前浏览器暂不支持标准全文在线预览服务,请使用现代浏览器(Chrome、Firefox、Opera、Microsoft Edge、360安全浏览器、搜狗浏览器、猎豹浏览器、傲游浏览器等)重新打开当前页面继续进行标准全文预览。

2011年10月31日 · 累计产量统计表:开始、结束、统计点时间的比较在确认每个时间的不同岗位的累计产量时:计算当前时间与某岗位的开始时间时(班次从早晨6:3015:0023:306:30)要比较某个时间比岗位开始时间大时才计算产量:如开始 ...Excel函数与公式

2021年6月24日 · (1)联系工艺,开工作票(联锁仪表开红票,其他仪表开白票),并要求工艺完成控制回路改手动,联锁仪表切除相应联锁。 (2)带上个人工具及其它相应工具,若变送器为智能型,须带上手操终端。 (3)介质含硫物质时必须随带H2S测试仪。 2、排污操作

2017年3月26日 · 中国科学技术大学

建筑物及桥梁、地基桩头剔除,凝土墙体开洞,水利枢纽的涵洞扩大,在坚硬的岩石上开挖地基或岩石清除,小型岩石隧道、坑道和壕沟的开挖与掘进,航道疏浚中的水下岩石或建筑物的破碎与清除等。 3、抢险和救灾方面

水磨磨坊又称:水磨房,由引水道、水轮、磨盘和磨轴等部分组成,它日夜旋转,磨面千斤,不但节约能源,而且是无污染的环保磨面工具。 网页 新闻 贴吧 知道 网盘 图片 视频 地图 文库 资讯 采购 百科

2025年4月14日 · 很不错,改装易加粉超级好用,就是搭配盖子不够两套硒鼓,下次再来购买。 品質非常好,價錢合理,值得購買,好評。 此用户没有填写评价。 用了一次,再也不加热了, .

京东是国内专业的加粉工具开孔器网上购物商城,本频道提供加粉工具开孔器商品价格信息,加粉工具开孔器价格,加粉工具开孔器图片精选,为您选购加粉工具开孔器商品提供全方位的价格 .

开方孔工具品牌/图片/价格 开方孔工具品牌精选大全,品质商家,实力商家,进口商家,微商微店一件代发,阿里巴巴为您找到234个有实力的开方孔工具品牌厂家,还包括价格,高清大图, .

2024年8月14日 · 2拆除缸头,将缸头及油封放指定位置。 3将柱塞小心取出放置。 6将缸头均匀套装紧固。 7将油缸吊置就位安装,恢复油管道,对缸体严密性和灵活性作检查试验工作。 关断门油缸解体检修 1将油管道拆除并封置好。 2拆除端盖固定螺栓,将缸体与关断门