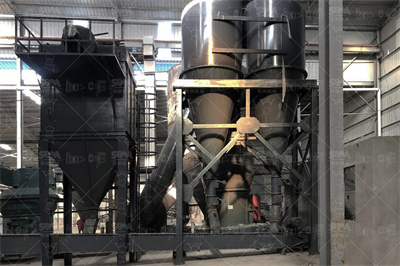

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2011年8月5日 · 千多平方公里的叙利亚南部领土戈兰高地(属于库奈特胜地区)被以色列占领,以色列在这 儿建立约42 个犹太人定居点,叙利亚为收回这块土地一直在做不懈的努力。 叙利亚 .

2024年12月7日 · 直新闻:那在您看来,叙利亚第二次爆发内战,最终又会对接下来的中东与世界局势产生什么样的影响呢? 特约评论员 刘和平:其实,叙利亚第二 ...

2023年1月10日 · 叙利亚的工业基础比较薄弱,经济规划承袭了苏联风格,以五年为一个发展计划周期,国营企业在国民经济中的起主导地位,工,矿、金融及保险业等大企业均由国家控制。 .

2024年12月7日 · 当地时间12月6日,伊拉克、伊朗、叙利亚三国外长在巴格达召开会议,商讨应对叙利亚危机。当晚,会议发表联合声明。声明指出,当天会议讨论了 ...

2024年12月15日 · 当地时间14日,以军总参谋长哈莱维视察驻扎在戈兰高地的以军部队时称,以色列不会干涉也无意管理叙利亚内部事务,以军在戈兰高地的战备旨在 ...

2024年9月24日 · 叙利亚的资源主要包括 石油、天然气和矿产资源。 以下是详细的解释: 首先,叙利亚石油资源是其重要的经济支柱之一。 叙利亚的石油储量虽然不像中东一些国家那样丰 .

叙利亚局势图(2025年1月13日) liveuamap 考虑到叙利亚政府所面临的上述内外矛盾和挑战,以及沙拉需要时间树立个人威信并提升其嫡系组织在议会 ...

2024年11月30日 · 每经编辑 张锦河 央视新闻报道,叙利亚军方当地时间11月29日发表声明说,叙利亚政府军当天在叙西北部地区与反对派武装和极端组织继续发生大 ...

2024年12月18日 · 近日,欧盟及其多个成员国正在加强与叙利亚过渡政府的联系,并就解除对叙利亚的制裁释放积极信号。据新华社报道,当地时间17日,欧盟外交与 ...

2024年12月23日 · 据统计,叙利亚已探明的矿产资源包括石油、天然气、磷酸盐、铜、金等。 这些资源在叙利亚的经济发展中起到了重要作用,尤其是石油和天然气资源,更是叙利亚能源产 .

2025年3月10日 · 摘要 叙利亚非金属矿销售行业注册公司具有资源丰富、政策支持等优势,但也面临基础设施薄弱、市场风险高和法律环境复杂等劣势。 本文将深入分析这些方面,为有意进入 .

转自: 新华网 新华社大马士革12月15日电 新华社记者冀泽 王卓伦 陈霄 "叙利亚沙姆解放武装"支持的叙过渡政府日前正式接管权力后,中东地区和 ...

2024年12月7日 · 与此同时叙利亚的地底下还埋着天然气、磷酸盐、铁矿石等一大堆的好东西。这些战略资源对东大来说自然都是非常不错的。最后叙利亚的和平稳定对东大来说非常重要。因 .

2024年12月12日 · 美国"防务博客"网站则透露,驻扎有叙利亚最精锐空中力量的苏韦达省哈勒哈拉空军基地遭到毁灭性打击,初步评估显示,部署在此地的米格29 ...

叙利亚磷矿市场开采与矿权投资前景预测报告二、叙利亚劳动力市场技工能力情况点评第四节叙利亚劳动力市场工会力量强弱程度判断一、叙利亚工会的发展状况综述二、叙利亚工会组织的罢 .

2024年12月16日 · "叙利亚沙姆解放武装"支持的叙过渡政府日前正式接管权力后,中东地区和域外一些国家纷纷作出反应。美国官员正与"叙利亚沙姆解放武装"和 ...

2024年12月11日 · 此外,叙利亚还有铁、铜、铀、钍及其他矿 种。 据外交部官网介绍,叙利亚的工业基础较薄弱。现有工业分为采掘工业、加工工业和水电工业,其中开掘工业主要有石油、 .

2024年12月29日 · 中青报·中青网记者 赵婷婷 叙利亚青年阿卜杜勒阿齐兹·阿尔马希怀揣着一个梦想:回到自己的祖国,积极参与国家的重建。然而,他告诉美国有线 ...

2019年7月27日 · 而这些磷酸盐矿石是叙利亚政府军仅有的在现在换取宝贵的外汇项目之一,但是在25 日晚间,叙利亚叛军的武装分子炸毁了霍姆斯省,叙利亚政府军的保护下的一列火车。 .

2024年12月15日 · "叙利亚沙姆解放武装"支持的叙过渡政府日前正式接管权力后,中东地区和域外一些国家纷纷作出反应。分析人士认为,叙政局剧变打破了外部 ...

2024年12月10日 · 叙利亚的散货船在该国的经济发展中发挥了不可或缺的作用。本文将深入探索叙利亚的 ... 粮食运输:作为一个农业国,叙利亚依然有不少粮食出口业务,尤其是谷物的运输 .