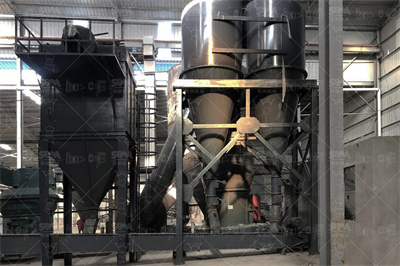

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

京东是国内专业的迷你粉碎机网上购物商城,本频道提供迷你粉碎机商品图片,迷你粉碎机价格,迷你粉碎机多少钱信息,为您选购提供全方位迷你粉碎机怎么样,迷你粉碎机好不好参考,提 .

阿里巴巴为您找到9,621个今日最新的纸粉碎机价格,纸粉碎机批发价格等行情走势,您还可以找市场价格、批发价格等相关产品的价格信息。 阿里巴巴也提供相关纸粉碎机供应商的简介,主营产 .

Online shopping for popular electronics, fashion, beauty, home garden, toys sports, automobiles and more products! Taobao Singapore. 淘宝让您随心淘超值商品,为您提供流行 .

现在的标签纸应用广泛,标签纸表面为一层印刷纸,底部为粘性胶,许多粉碎机在粉碎过程中会因粘性胶的特性产生粘刀现象,谷安机械根据这一特性,发明了这款碎纸机,专为标签纸、不干 .

阿里巴巴不干胶粉碎机 可以碎不干胶 双面胶 标签纸 胶贴铭牌粉碎,粉碎机,这里云集了众多的供应商,采购商,制造商。 这是不干胶粉碎机 可以碎不干胶 双面胶 标签纸 胶贴铭牌粉碎的详 .

五谷杂粮磨粉机(0 ) 专属代理 VIP渠道 * 产品名称: 我想了解: (可多选) 详细合作政策 产品详细资料 ... 龙骨 牛骨粗碎机 铁质碎纸机 不锈钢粗碎机罗汉果粗碎机 旭朗厂家直发不锈钢食品粗碎 .

2025年2月18日 · 工作原理: 本机的粉碎室有动盘上多排动针和静盘上多排静针组成,动针与静针有规则的交错排列。工作时空气与物料同时进入,物料通过定量加料器进入粉碎腔中心后,高 .

碎纸机 标签打印设备 其他打印设备 复合机 打印机 投影配件 3D打印设备 更多 高级选项: 杯体材质 ... 京严打粉机超细研磨机家用中药粉碎机小型打碎五谷杂粮料理胡椒磨粉机 豪华款【12叶精钢 .

京东是国内专业的奥力粉碎机网上购物商城,本频道提供奥力粉碎机商品图片,奥力粉碎机价格,奥力粉碎机多少钱信息,为您选购提供全方位奥力粉碎机怎么样,奥力粉碎机好不好参考,提 .

CN10/CNPP品牌数据研究部门通过资料收集整理,并基于大数据统计及人为根据市场和参数条件变化的分析研究专业测评而得出,是AI人工智能、大数据、云计算、数据统计真实客观呈现的 .

2013年9月13日 · 9_上海碎纸机厂家,上海数纸机经销商,上海配页机订_上海森永办公 上海HSM碎纸机维修+IDEAL碎纸机维修+PRIMO碎纸机维修 本公司是上海专业的碎纸机销售维修保养租赁 .

碎纸机 投影配件 标签打印设备 高级选项: 适用人数 适用场景 基础功能 出面类型 类别 类型 主体材质 动力类型 容量 ... 琪扬磨粉机小麦玉米磨面粉碎面机五谷杂粮全自动打粉机粮油多功能设备 .

中国制造网为您提供专业的碎纸机产品价格信息和生产厂家信息查询平台,方便您快速找到碎纸机产品优质供应商。

2.本类似群与第八版及以前版本的0709磨粉机(机器),离心碾磨机交叉检索;3.跨类似群保护商品:磨粉机(机器)(0709,0725);离心碾磨机(0709,0723,0725);粉碎 .

这是嘉力豪JIS-600发票碎纸机,票据粉碎机,卡片粉碎机,书本粉碎机的详细页面。 品牌:嘉力豪,型号:JIS-600,碎纸能力:200(张/次),碎纸效果:不规则碎片状,额定电 .

主要设备: 磨粉机100 台 公司工艺: 其他机械五金工艺 长期供应高品质SMW500660磨粉机轴 磨粉 ... 主营产品: 塑料粉碎机 工业碎纸机 慢速粉碎机 中速破碎机 碎料机 双轴撕碎机 除湿干 .

三维模型网为各位工程师提供3D模型、CAD图纸下载,还包括自动化设备|非标设备|模具|机器人|机床|输送机|夹具|机械手|组装机|焊接机|包装机|流水线|检测机|点胶机|生产线|贴标机|传送带|锁螺 .

2025年4月18日 · 您在查找商标纸团粒磨粉设备价格吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

碎纸机 其他打印设备 打印机 复合机 标签打印设备 喷墨打印机 收银机 3D打印设备 装订/封装机 ... 拜杰磨粉机打粉机超细研磨机小型中药粉碎机家用五谷杂粮辅食料理机 第十代升级款【五重豪 .

碎纸机 激光笔 鼠标 CPU 工具软件 行业软件 化工仪器仪表 充填机械 包装清洗机 集装机、堆码机、码垛机 辅助包装机械 其他切削刀具 兽医专用设备 航标航道器材 紫外线/辐射消毒灭菌设备 .

惠利得科密碎纸机办公室专用全自动办公家用家庭商用迷你小型粉碎机5级 全自动款( 80张自动碎 连续35分 已有 0 人评价 家用小型磨面机全自动小麦磨粉机干湿两用打粉机超细研磨机粉碎机 .

2023年3月2日 · 当前位置: 首页 办公设备 办公仪器 其他办公设备 碎纸机 CHIGO/ 志高碎纸机 文章详情 极速发 CHIGO 志高 中药粉碎机磨粉机家用打粉机超细研磨机破碎机磨面机药材小型 ...

2021年8月19日 · 农机网为您推荐的产品瓦楞纸粉碎机是由郑州九龙机械设备有限公司提供,当前页面为瓦楞纸粉碎机的产品详细介绍页面,包含了瓦楞纸粉碎机产品的图片、价格、报价、型 .

京东是国内专业的粉碎机型号网上购物商城,本频道提供粉碎机型号型号、粉碎机型号规格信息,为您选购粉碎机型号型号规格提供全方位的价格参考,提供愉悦的网上购物体验!

2023年12月9日 · 谷安机械的广告纸、标签纸粉碎机采用高速马达,剪切式刀具角度粉碎,使标签纸碎成颗粒式形状,达到更强保密效果。 现在的标签纸应用广泛,标签纸表面为一层印刷纸, .

2020年4月1日 · 一般生产破碎机的厂家在设备上贴上的彩色编码安全标志分为三大类,这三大类分别为:1.红色禁止标志,禁止标志的含义就是绝对不允许做;2.蓝色强制标志,强制标志的含 .

600型刀盘磨粉机,PVC商标纸、扣板、型材、管材磨粉机厂家供应 张家港市普金机械有限公司 5年 月均发货速度: 暂无记录 江苏 张家港市 ¥ PP商标纸磨粉机 广告纸打粉机 铜版 .

2025年3月1日 · 您在查找胶纸磨粉机吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

2021年7月22日 · 保险柜 录音笔 监控摄像头 收银机 碎纸机 考勤机 装订机 点钞机 翻译笔 翻译机 功放设备 切纸机/裁纸机 视频会议会议室终端 塑封机 检测门 文印图像 传真机 复印机 多功能 .

钙粉,又称碳酸钙、石灰石,用超细磨粉机粉碎,细度目可调,客户原料120目作用,要求d97 10微米全通过。物料经入料口进入超细磨粉机,经磨粉机内粉碎盘与齿圈的高速剪切粉 .