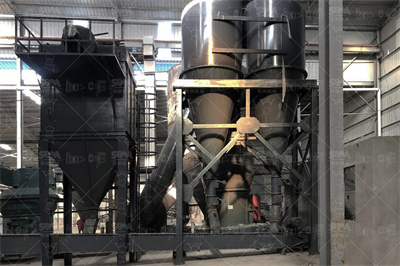

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

MTX欧版梯形磨粉机,欧版磨粉机,欧版磨 MTW欧版磨粉机该机型采用了锥齿轮整体传动、内部稀油润滑系统、弧形风道等多项技术。性能稳定,操作方便,能耗低可调可控成品粒度、粉磨物料应用广泛配备专用除尘器,粉尘排放浓度完全低于国家环保规定。

气压磨粉机检修操作规程和平区报价,和平区气压磨粉机检修操作规程生产商,气压磨粉机检修操作规程厂家KVOV ... MTW欧版T形磨粉机 MTM中速T 形磨粉机 MTM中速T形磨粉机 产品概述:MTM中速T形磨粉机是上海世邦公司在多年研发工业磨粉机的基础上,引进 ...

2017年8月15日 · 欧式梯形磨粉机资料.pdf,MTW175型 欧式梯形磨粉机 用 户 手 册 上海世邦机器有限公司 24 1 共 页 第 页 110921版 目 录 一、 欧式梯形磨粉机的用途 (3) 二、磨粉机的规格、性能 (3) 三、 工作原理、整机结构特征 (4) 四、整机的安装、调试 ...

欧版梯形磨粉机安全操作规程 欧版梯形磨粉机 低阻力悬辊磨曲面风道号ZL用于磨粉机的曲面铲刀号ZL用于梯形磨的锥齿轮传动润滑装置号ZLMTW系列欧版梯形磨粉机是黎邦明重工权威专家吸收欧洲粉磨技术及 ...

三、 工作原理及整机结构特征 MTW215 型欧式梯形磨粉机整机结构是由主机、笼形选粉机、管道装置、 离心引风机、旋风集粉器、布袋除尘器、星形卸料阀组成,其附属设备由锤式 破碎机 .

供应高压梯形磨粉机的详细描述:高压梯形磨粉机超压梯形磨粉机工作原理:将需要粉.使之了解磨粉机的原理性能,熟悉操作规程。 2、为使磨粉机正常,应制定设备"设备保.方能保证磨机长 .

欧版反击破检修规程 欧版反击式破碎机PFW1315 Ⅲ厂家 欧版梯形磨粉机原理 欧版梯形磨粉机 MTW系列欧版梯形磨煤机,是我公司专家在长期磨粉机研发经验基础上,采纳9518位磨粉机使用客户的建议,经潜心研究创新设计出来的型的磨煤机。MTW欧版梯形磨 ...

2025年4月8日 · 欧版梯形磨粉机介绍 欧版磨主要由主机选粉机风机颚破畚斗提升机电磁振动给料机储料仓布袋除尘器管道装置旋风集粉器电控柜电 机等组成。无阻力进风蜗壳(小观察门无涡流):采用内部门板内面与进风蜗壳内面在同一曲面上,能有效的

2018年3月9日 · 欧版磨检修防护装置 ZL 2014 2 |欧版磨智能自动调节控制器 ZL 2015 2 |欧式梯形磨粉机 ZL 2013 3 MTW欧版磨主要由主机、选粉机、风机、颚破、畚斗提升机、电磁振动给料机、储料仓、布袋除尘器、管道装置、旋风集粉器、电控柜、电机等 .

2024年2月28日 · 欧版磨粉机是一种先进的粉磨设备,具有高效节能、环保低噪、操作简单、维修方便等优点。在使用欧版磨粉机时,应严格遵守操作规程,定期进行维护和保养,合理使用设备,以确保设备的性能和寿命。

这是上海世邦炉渣加工磨粉机 MTW138欧 ... MTW138欧版磨粉机报价清单福州报价,福州MTW138欧版磨粉机报价清单生产商,MTW138欧版磨粉机报价清单厂家KVOV信息发布网 26年的精工制造, 为全球客户打造了款的磨粉设备,所向粗粉、细粉、超细粉深加工

2013年1月9日 · 欧版梯形磨粉机检修规程 欧版梯形磨粉机恒天重工股份有限公司中国设备网 设备详细 设备参数 公司其他产品 矿业网 买卖欧版梯形磨粉机,上 MTW系列欧式梯形磨粉机,是我公司专家在长期磨粉机研发经验基础上,采纳9518位磨粉机使用客户的。

新型吊挂式笼式选粉机结构设计 MTW欧版磨粉机是我公司在吸收粉磨技术及理念的基础上研发而成的国家专利产品,拥有多项自主专利技术产权。该机型采用了锥齿轮整体传动、内部稀油润滑系统、弧形风道等多项新型专利技术,磨粉效率高,产量大,是传统雷蒙磨、摆式磨更新换代替代产 .

2013年3月8日 · 一、欧式梯形磨粉机性能优势 1、锥齿轮整体传动 传统磨机需另有减速机、通过联轴节传动主轴 安装时对中难度大 易产生噪音 降低效率 MTW 系列欧式梯形磨为锥齿轮整体传 .

欧版梯形磨粉机的应用,产品导航磨粉机欧版梯形磨粉机欧版梯形磨粉机作者:重工重工科技网发布时间:浏览:性能特点适用范围工作原理技术参数设备组成下载下载使用手册具有国际先进技术水平,拥有多项自主技术产权的粉磨设备系列欧式梯形磨粉机,是我公司专家在长期的磨机研发经 .

欧版鄂破机检修规程鄂式破碎机的正常运转,不仅需要按照正确合理的方法进行操作,而且需要定期对设备进行检修工作,及时更换磨损较为严重的部件等。

8、振动给料的控制及给料按照其配套说明书执行。 五、磨粉机的操作规程 开动磨粉机前,应检查所有检修门关闭是否严密,检查锤式破碎机的颚板 间隙是否符合进料粒度尺寸,调整选粉机转速应达到近似成品粒度要求。

2012年11月10日 · 沥青产品信息主要以20万吨超细矿渣欧版梯形磨粉机安全操作规程,矿山设备厂家年月日 超细磨粉机,超细立式磨,磨粉机厂家化工、煤炭、立磨检修安全注意事项及安全安全 .

欧版梯形磨粉机工作原理,上海世邦机器有限公司成果具有国际先进技术水平,拥有多项自主技术产权的粉磨设备系列欧式梯形磨粉机,是我公司专家在长期的磨机研发经验的基础上,根据位磨粉机用户的使用与建议,经潜心研究创新设计出的型磨粉机,该机型采用了锥齿轮整体传动、内部稀 .

2012年8月16日 · 中速梯形磨粉机独特设计改善_机电之家 磨粉机也从原来的雷蒙磨粉机不断升级换代为中速梯形磨粉机、S超细磨粉机到现在的欧版T型磨粉机和大型立式磨粉机;尤其是制砂机,更是该公司的龙头产品,具有自制研发。

2012年10月24日 · 能不能说一下mtm130梯形磨粉机最贵的有多少钱?mtm。 1300复合圆锥破最重检修件重量 MTM系列梯形磨粉机细碎机给力促销了价格打折,质量不打折!价格信息 MTM系列梯形磨粉机细碎机给力促销了价格打折,质量不打折!信息 当前价格: ≥1:。