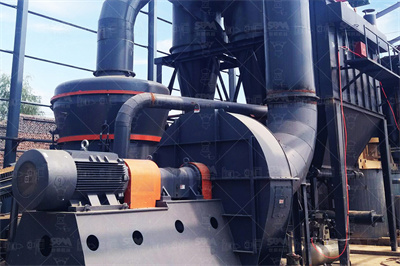

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2024年1月21日 · 对于石灰石的完全煅烧并且没有未煅烧石灰石的残余核心,供应到石灰石表面的热量必须通过传导热传递到核心渗透是必要的。 由于材料内部的气氛是纯 CO2,因此堆芯中的温度至少要在短时间内达到 900 摄氏度。

2024年7月21日 · 从粒度与均匀性、孔隙率与密度、煅烧速度与温度、以及燃料配比与窑内气氛等方面,详细探讨石灰石粒度对煅烧过程的影响。 一、粒度与均匀性对煅烧过程的影响

O_2_CO_2气氛下石灰石煅烧分解的动力学和热力学研究4 O2/ CO2 气氛下石灰石煅烧分解的热力学 分析 通过热力学分析可以确定化学反应的平衡条件 ( 或破坏化学平衡的条件), 这对于化学分析 、工业设 计都具有重要意义 。 石灰石煅烧分解反应 ( 4) 为吸 热反 ...

2013年12月13日 · 空气燃烧与O2CO2燃烧气氛下水蒸气对石灰石煅烧硫化特性的影响 星级: 7 页 暂无目录 点击鼠标右键菜单,创建目录 暂无笔记 选择文本,点击鼠标右键菜单,添加笔记 暂无书签 在左侧文档中,点击鼠标右键,添加书签 ...

2023年9月25日 · 煅烧温度的高低直接影响到石灰石的分解效果和石灰质量。一般要求煅烧温度在℃之间。控制气氛。在石灰石煅烧过程中,需要控制窑内气氛为弱还原性,以避免石灰石出现过多烧结现象。控制烧成时间。石灰石的烧成时间对其质量和产量有着重要影响。

2011年6月30日 · 据此创造条件来满足石灰石的煅烧气氛 : (1)减少产物[WTBZ]CO 2 气体的压力,即采用风机不断抽出窑气混合物,从而使Q P 降低。 (2)提高温度 ...

针 对 O2/ CO2 气氛下 石灰石 煅烧分 解 特性进行了热 力学分析和热重试验结果的动力学分析, 将热 力学分 析结果与 热重试 验结果 进行了 对比, 得出石 灰 石的起始分解温度随 CO2 分压比的增大而增高 。 关键词 : O2/ CO2 气氛 ; ...

关键词: 石灰石, 白云石, 煅烧 / 碳酸化, CO 2 捕集 Abstract: The main system parameters, including long term cyclic carbonation conversion, average carbonation conversion, CO 2 capture efficiency and energy requirement for a calciner in the two kinds of typical calcination atmospheres, including pure N 2 and high concentration CO 2 were investigated by experiment .

焙烧是在有过量空气或氧气的情况下进行的。氧化气氛对于将硫化物转化为氧化物或去除杂质的化学反应至关重要。 温度: 煅烧: 煅烧温度通常低于所处理材料的熔点。例如,石灰石的煅烧温度约为 900°C 至 1000°C。 焙烧:

2024年1月18日 · 在高温下,石灰石分解更完全,得到的氧化钙具有更高的活性。一般来说,煅烧温度越高,石灰活性度越高。但温度过高会导致石灰过烧,反而降低活性度。因此,选择合适的煅烧温度是提高石灰活性度的关键。气氛控制:气氛对石灰石的煅烧具有重要影响。在

由于此网站的设置,我们无法提供该页面的具体描述。

本文研究了在O2/CO2气氛 下石灰石的煅烧和烧结特性.结果表明,空气气氛下煅烧所得CaO的孔隙率和比表面积均较O2/CO2气氛下的大,但O2/CO2气氛下煅烧所得CaO具有 更大的最可几孔径.石灰石在O2/CO2气氛下1000℃煅烧时的产物具有最大的比孔容积和比

2017年6月27日 · 摘要: 采用恒温热重实验台研究了循环流化床内石灰石同时煅烧硫化反应中煅烧反应与硫化反应的相互作用。当煅烧环境中存在SO 2 时,煅烧反应与硫化反应同时发生,并在颗粒中生成CaSO 4。与纯煅烧工况相比,在含有SO 2 的气氛中煅烧石灰石时,颗粒的质量下降速率降低,而煅烧终质量升高。

2012年11月15日 · 氛下石灰石煅烧不硫化反应特性及其影响因素,同 时结合压汞分析和扫描电镜等微观手段分析O2ΠCO2 气氛下石灰石硫化反应机理。1O 2 ΠCO 2 气氛下石灰石煅烧分解的热力学 分析 石灰石煅烧分解反应(1)为吸热反应,温度升高 会促使反应向正斱向迚行。由于

煅烧实践举例: 石灰生产:石灰石(CaCO₃)经煅烧可制成生石灰(CaO),用于建筑、水处理和化工生产。 催化剂活化:在石化工业中,煅烧催化剂可去除杂质并提高其活性。 陶瓷釉料制备:对高岭土等原材料进行煅烧,可提高其在釉料中的稳定性和性能。

煅烧,或称锻烧(英语:),是指将固体在空气或氧气中加热到高温,通常是为了去除杂质或挥发性物质。然而,煅烧也被用来指在缺乏或有限的空气或氧气供应的情况下,对矿石和其他固体材料进行热处理,从而导致热分解。单词calcination的词根指的是它最显著的用途,即通过燃烧从石灰 .

摘要:富氧燃烧是一种能够综合控制燃煤污染物排放的新型洁净燃烧技术。 针对 O2 / CO2 气氛下石灰石煅烧分解 特性进行了热力学分析和热重试验结果的动力学分析,将热力学分析结果与热重试验结果进行了对比,得出石灰. 由热力学第二定律,式(9)的平衡条件为 !GT = 0。 令 !GT = .

2017年11月27日 · 富氧燃烧气氛下石灰石煅烧%硫化特性及模型模拟.pdf,第 66 卷 第4 期 化 工 学 报 April 2015 2015 年 4 月 CIESC Journal ·1537 ...

2014年11月7日 · 态改变. 因此,研究石灰石煅烧过程中孔隙结构演变规 律有助于从微观角度分析其分解机理的动态变化本质. 有关石灰石完全煅烧后的多孔结构对其脱硫/吸收 反应性能影响方面已有很多报道[16,17],如Reyes 等[18] 在煅烧石灰石硫化反应建模研究中指出,石灰石

Abstract: Oxygenenriched combustion of coal is one of the new technologies that can control pollutants emission. Thermodynamic analysis for calcination of limestone under O2/CO2 atmosphere in fluidized bed condition was carried out, which is accorded with the TG (Thermal .

2023年12月21日 · 白灰窑的原料主要是石灰石,其成分和纯度对煅烧过程和产品质量有重要影响。在煅烧过程中,需要合理控制原料的投料速度和料层厚度,确保原料在窑内均匀受热并充分分解。 白灰窑的煅烧过程是生产优质石灰的关键环节,涉及原.