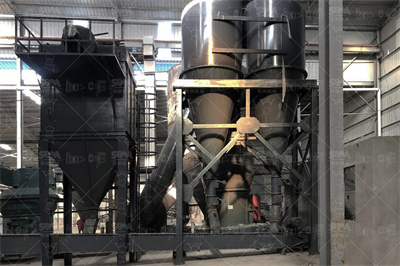

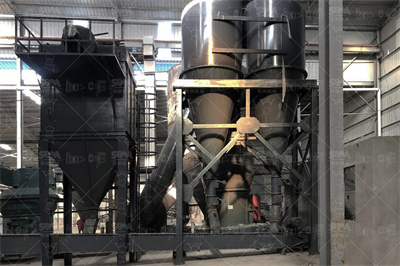

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

1 天前 · 您在查找pfa粉碎机吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

阿里巴巴为您找到82个今日最新的硫酸钒价格,硫酸钒批发价格等行情走势,您还可以找市场价格、批发价格等相关产品的价格信息。阿里巴巴也提供相关硫酸钒供应商的简介,主营产品,图片,销量等全方位信息,为您订购产品提供全方位的价格参考。

本图片来自永嘉县扬子江泵业有限公司.提供的自吸泵:ZW型不锈钢自吸排污泵|自吸污水泵|无堵塞自吸泵,型号为ZW的离心泵,产地为温州,属于品牌,参考价格为 1万元以下,公司还可为用户供应高品质的自吸泵:ZXPB不锈钢防爆自吸泵|自吸式化工泵、化工泵:FS型卧式玻璃钢离心泵等产品。

16 小时之前 · FZB系列氟塑料自吸泵是按国际标准并结合非金属泵的工艺设计制造,其特点是: FZB泵泵体采用金属外壳内衬氟塑料,过流部分全都采用氟塑料合金制造,泵盖、叶轮等均用金属嵌件外包氟塑料整体烧结压制而成,轴封采用外装式*的波纹管机械密封,静环选用%氧化铝陶瓷(或氮化硅),动环采用四 ...

阿尔法新材料(辽宁)有限责任公司主要经营氟塑料PTFE波纹管(可导电),氟塑料PTFE平管,氟塑料PTFE内平外波软管,氟塑料PTFE热缩管一系列产品,公司位于盛福大厦,阿尔法新材料公司是中国荷兰合资企业,致力于含氟高分子材料的新技术、新工艺、新产品的研发与应用。

2020年12月22日 · 供应25FSB10化工泵,氟塑料化工离心泵,化工泵价格,卧式化工泵是当今世界*秀的耐腐蚀材料,我单位选用该材料生产的FSB、FSBD系列氟塑料合金离心泵,具有特强的耐腐性,且机械强度高、不老化、无毒素分解,可输送任意浓度的酸、碱液、氧化剂及其他腐蚀

2024年7月16日 · TMF氟塑料磁力泵由山东中元泵阀有限公司发布,为您提供产品的价格报价、详细参数、规格型号、产品参考图片等信息,厂家多类产品一应俱全,欲了解更多TMF氟塑料磁力泵的产品参数、实时报价、市场行情等信息,请访问塑料机械网!

2023年10月21日 · 公司开发的氟塑料拉管机、氟塑料包线机、钢管包塑机、铁丝包塑机等设备,现已被多家企业选用并得到高度认可。 高质量的产品,完善的售后服务,诚信的合作,是公司的 .

16 小时之前 · 制药机械设备供应网会员企业天津市星宇达泵业制造有限公司提供IHF氟塑料化工离心泵,一、用途适用于在20—105℃条件下长期输送有腐蚀性粘度类似于水的液体。特殊情况温度可达200℃.如化工、冶金、电力、石油、制药、农药、染料、油漆、冶炼、造纸、合成纤维

2022年8月3日 · 详细摘要: 回转窑是指旋转煅烧窑(俗称旋窑),回转窑是水泥熟料干法和湿法生产线的主要设备,同时广泛用于冶金、化工、建筑耐火材料、环保等工业。 详细摘要: 烘 .

1 天前 · 产品概述: CQB系列氟塑料磁力驱动泵,采用磁力耦合传动,不存在动密封点,因此杜绝了一般轴传动式离心泵轴封处跑、冒、滴、漏的现象。其过流部件采用氟塑料及高纯度工业陶瓷制成,具有优异的耐腐性及密封性,因此广泛用于化工、医药、铝箔、制酸、涂装、有色金属等行业及易燃易爆、易 ...

16 小时之前 · 塑料机械设备供应网会员企业常州双诚热工仪表厂提供替代四氟型防腐玻璃转子流量计专业厂家,PVDF玻璃转子流量计DK900概述是一种测量封闭管道中单相非脉动流体(液体或气体)流量过程检测仪表,于强腐蚀介质的测量,有耐强酸强碱的腐蚀 ...

3 天之前 · 关于我们 上海长征泵阀(集团)有限公司位于中国上海汽车城安亭镇黄渡工业园区,一家以研究生产节能水泵、离心泵等各类多元化水泵产品的外向型老牌水泵厂家。一个水泵品牌的崛起,历经商海锤炼,四十年来,上海长征泵阀从国有到股份制发展到现在,拥有了三个生产基地七个子公司、二十多家 ...

2 天之前 · CQBF氟塑料磁力泵 是本单位开发的新产品,并引进技术,采用聚偏二氟乙烯制造,该材料是目前优秀的耐腐蚀材料,用该材料生产的磁力泵使用范围广,耐腐蚀性能强,机械强度高,不老化,无毒素分解等优点。 可广泛用于化工、制药、电镀、石油、环保、稀土分离、冶炼、汽车制造中的酸洗等领域。

蘑菇磨粉机 产品介绍 产品信息 蘑菇万能粉碎机主要适用于化工、染料、助剂、饲料、食品、医药、木屑、化纤及非金属矿等中低硬度物料的粉碎加工,细度在20120目之间调节,具有产量高、粒度细、噪声低、能耗低、维修简单、安装方便等优点,特别 ...

阿里巴巴为您找到51条ptfe磨粉机产品的详细参数,实时报价,价格行情,优质批发/供应等信息。

格雷斯是国内成员之一的塑料挤出和回收设备供应商,运用科学、技术以及"人元素"的力量不断改进推动产品进步的基本要素,为**70个地区和地区的客户提供种类繁多的产品及服务,具体产 .

阿尔法新材料公司是中国荷兰合资企业,致力于含氟高分子材料的新技术、新工艺、新产品的研发与应用。 主要投资方之一的荷兰Fluortubing BV公司沉浸于聚四氟乙烯PTFE分散树脂管材的 .

2019年8月20日 · 智能制造网为您推荐的产品SJ90SJ100塑料挤出机是由北京泽岛机械有限公司提供,当前页面为SJ90SJ100塑料挤出机的产品详细介绍页面,包含了SJ90SJ100塑料挤出机产品的图片、价格、报价、型号、产地及供应商联系方式等信息。大家都在造挤出机,众多生产线也离不开挤出机。什么是好的挤出机?公说 ...

2018年5月14日 · 氟塑料合金是当今世界*秀的耐腐蚀材料,我单位选用该材料生产的FSB、FSBD系列氟塑料合金离心泵,具有特强的耐腐性,且机械强度高、不老化、无毒素分解,可输送任意浓度的酸、碱液、氧化剂及其他腐蚀性介质,因而广泛适用于化工、石油、制药、农药、冶炼、染料、造纸、电镀、食品等行业 。

2016年11月22日 · SJ系列新3#钢PFA、F46氟塑料造粒... SGP1000型风送集料破碎机塑料粉碎... 为什么那么多的公司选择我们! 或按要求,制作图纸。 也可提供现场安装服务,实现"转建"工 .

强力型塑料破碎机主要用于破碎各种热塑性塑料和橡胶,如塑料异型材、管、废旧橡胶制品、粒料可直接供挤出、注塑之用。 具有破碎能力大,产量高,工作性能稳定等特点,可根据用户需要 .

2006年6月8日 · 粒状聚四氟乙烯互动百科 粒状聚四氟乙烯 PTFE的基本概况 氟树脂(常称氟塑料) ... 机资讯,和粉机图片,和粉机厂家等 【精品推荐】聚四氟乙烯液压磨粉机铁和不锈钢材质磨粉机 立式50简装和面机和面机器搅拌面粉机商用揉面机.