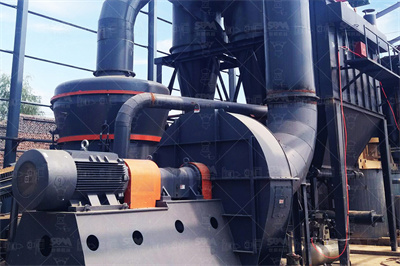

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2013年10月20日 · 无刷角磨机使用寿命是多长? 2 牧田角磨机碳刷的使用寿命? 28 无刷角磨机真的耐用吗,具体能用多长时间? 1 抽油烟机的使用寿命一般是多长 158 长时间使用一台角磨机好吗? 听说无刷角磨机不用换碳刷,有啥好处吗?

珩磨一般采用 珩磨机,机床主轴 与珩磨头一般是浮动联接;但为了提高纠正工件 几何形状 的能力,也可以用 刚性联接。珩孔时,珩磨头外周一般镶有2~10根油石,由机床主轴带动在孔 内旋转,并同时作直线往复运动,这是 主运动;同时通过珩磨头中的弹簧或液 压力控制 油石均匀外涨,对被加工 .

2023年9月15日 · 1、 短筒球磨机:筒体长度L小于筒体直径D的2倍,即L≤2D的球磨机为短筒球磨机,其通常为单仓结构,主要用于粗磨作业或一级磨作业,其作业效率较高,可以实现23台 .

2025年4月22日 · 磨机越长,投入磨机的研磨介质和材料就越多,从而可以提高产量。 此外,磨机的长度会影响材料与磨机的停留时间,从而影响最终的颗粒尺寸以及最佳性能。

磨机主要参数的确定棒球磨棒仓的填充率主要取决于与后面各仓粉磨能力的平衡。单纯的棒磨机,其填充率可达到 。较高的填充率对产品质量有利。作为棒球磨的棒仓来说,根据生产经验,也可沿用钢球仓的填充率。四、磨机功率的计算1)托瓦洛夫公式,式

2021年12月17日 · 国外大部分选厂的常规碎磨流程是由破碎机、棒磨机、球磨机组成,我国选矿厂采用棒磨机的不多,球磨机的给矿 ... 为磨棒,一般认为磨棒的长度不应超过7米,因为过长的磨棒很易造成缠绕,因此,所用的棒磨机,长度没有太长的,磨 棒直径为75~150毫米 ...

2025年3月25日 · 关于我们 郑州治世长云科技有限公司,伊始于2009年,总部坐落于郑州电子电器产业园内,是一家集研发、制造、销售为一体的综合性企业,业务版图涵盖机械、通讯、工程设备等领域;公司自组织发展模式,带动了一批有想法,有干劲的上进青年,他们以振兴民族工业为己任,立志为祖国经济发展 ...

磨机根据磨矿介质和研磨物料的不同,可分为:球磨机、柱磨机、棒磨机、管磨机、自磨机、旋臼式辊磨机、立磨、多层立磨、立式辊磨机、盘磨机、DMC磨机等。陶瓷工业生产中普遍采用间歇式球磨机,采用湿法生产,其研磨作用可分为两个部分,一是研磨体之间和研磨体与简体之间的研磨作用,二是研磨体下落时的冲击作 . 展开 适用于粉碎重晶石、方解石、钾长石、滑石、大理石、石灰石、石膏、石英石、活性白土、活性炭、膨润土、高龄土、玻璃、锰矿、钛矿、铬矿、矿渣等莫氏硬度不大于7级,湿度在6%以下的非易燃 . 展开

管磨机是近代工业上一种很重要的细磨设备,是粉磨系统中最常见的重要设备之一,大型管磨机的生产能力很高。单仓管磨机和短筒球磨机不同的地方仅在于它的长度比直径大27倍,物料在管磨机中经历的时间较长,产品细度均匀,粉碎比较大。实际上多仓管磨机较单仓式应用得广泛。在多仓 .

2024年1月8日 · 建筑施工临时用电三级箱接电动工具允许电缆线长度是多长? 亲!您好。建筑施工临时用电三级箱接电动工具允许电缆线长度是**三十米**。 规范规定:分配电箱与开关箱的距离不得超过30m,开关箱与其控制的固定式用电设备的水平距离不宜超过3m。

磨矿机是一种磨碎矿石的开采设备。原料通过空心轴颈给入空心圆筒(其两端有端盖)进行磨碎。圆筒内装有各种直径的磨矿介质(钢球、钢棒或砾石等)。优点是操作方便、便于矿浆自主流及矿浆分配。磨矿机有若干种分类方法,其中最实用的分类方法是根据磨矿介质不同来划分的:介质是金 .

2023年10月8日 · 大有迷你磨,轻巧,转速高,长时间使用不累,国内一线品牌嗯,做工好,非常不错,侧开关使用方便,比后开关要安全,外形好看,经典,还送有两块磨片 3、东成 WSM710100 角磨机 此款东成多功能角磨机,是采用高品质铜线的电机,大功率电机效率强劲

2023年11月23日 · 150,180角磨机和230角磨机属于工业级的角磨机,150尺寸的同样适合家庭使用,在pdd看到的,有线角磨机。 价格优势,还可以。 大尺寸的在打磨大型物件有优势,可以切割更厚的金属,由于接触面增大,摩擦力和反弹的可能性也增大,必须严格遵从安全规范操作。

2017年12月12日 · ①短筒球磨机:筒体长度L 小于筒体直径D 的2 倍,即L≤2D 的球磨机为短筒球磨机,其通常为单仓结构,主要用于粗磨作业或一级磨作业,其作业效率较高,可以实现23 台 .

2020年12月27日 · 角磨机功率越大越好吗 5 角磨机功率1200与800哪个好,要转速大的还是小的比较好? 5 切线槽角磨机功率大好,还是小好 3 无刷角磨机比有刷角磨机功率大还是小? 家用角磨机为什么小功率的必大功率的还要贵?

2023年9月16日 · 管磨机是指长径比在4以上的磨机,筒体可分为两仓或三仓,又称水泥磨。管磨机一般用于水泥厂干法粉磨生料和熟料,也可用于化工、冶金等行业,经过特殊改造可用于细磨 .

最后更新2025年04月24日 专业咖啡知识交流 更多咖啡豆资讯 请关注咖啡工房(微信公众号cafe_style ) 家用咖啡磨豆机怎么选择?分析各种磨盘的优缺点。 磨豆机一般以咖啡萃取方式分类,分为单品咖啡磨豆机和意式咖啡磨豆机两大类!按磨盘结构分可分为平刀、锥刀、鬼齿三大类!

2009年9月10日 · 棒球磨机的长径比应在5左右为宜,棒仓长度与磨机有效直径之比应在—之间,棒长比棒仓短100mm左右,以利于钢棒平行排列,防止交叉和乱棒。 (4) 砾石磨 磨内装入 .

2016年11月13日 · 水泥球磨机主要用于水泥厂成品及原料的粉磨,也可用于冶金、化工、电力等工矿企业粉磨各种矿石及其它可磨性物料。本公司生产的水泥磨具有环保无污染,低能耗产量大,无故障运行时间长等优点。公司可根据用户对粉磨细度和产量的不同需求设计制造满足用户生产需要

非金属矿工业中常用的磨矿设备有球磨机、棒磨机、砾磨机、自磨机、悬辊磨(雷蒙磨)、压辊磨、冲击磨、涡轮磨、振动磨等。以下分别予以介绍。磨矿设备的发展趋势是磨机大型化,发展高效节能球磨机,发展细磨和超细磨设备。