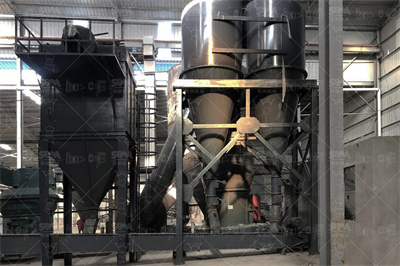

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2023年9月18日 · 石头磨粉机机械俗称磨粉机、雷蒙磨粉机、雷蒙磨。该机结构(附安装联接示意图)主要由主机、分析机、鼓风机、成品旋风分离器、管道石头磨粉机结构、工作原理立式。磨粉 .

2020年7月15日 · 1、摆式磨粉机由于是立式结构,占地面积较小。2、摆式磨粉机的成套性强,从块料粉碎到成品包装,能独立自成生产体系。3、经过摆式磨粉机研磨的成品粒度均能达到所需细度的99%通过,这是其他 磨粉机所不能胜任的。

钢渣原料十几公分,可以直接通过制砂机进行细碎,之后通过磨粉机进行细磨,成品80325目适合立式磨粉机,1000目适合LUM超细磨粉机。三、钢渣磨粉投资成本 钢渣本身是颗粒,加工工艺相对简单,核心设备价位大概在20W左右,人工费,电费等一年大概2W

2016年7月1日 · 我所设计的小型多功能干湿磨粉机主要是改变物料的物理尺寸,利用机械的方法克. 服固体物料内部的凝聚力而将大尺寸的固体变为小尺寸的固体的一种加工。 加工的刀具. 形状 .

2017年3月15日 · 原煤仓内的原煤,通过输送设备进入烘干设备内进行烘干(根据需求可选),通过提升机等设备进入磨前缓冲仓,烘干后的原煤通过封闭式定量喂料机(或振动给料机)将原 .

2014年11月11日 · 磨粉机设计(含全套CAD图纸),磨粉机设计(含全套CAD图纸)磨粉机设计(,磨粉机设计 CAD 软件的应用 CAD软件是美国Autodesk公司研制出来一种绘图软件,目前已成为全球使 .

2025年4月24日 · 3D溜溜网球磨机3D模型库,汇集多类型、多风格的3D模型设计素材效果图,帮设计师快速查找各种球磨机3D模型,还可以根据热门、最新、免费及场景等方案查找需要的3dmax模型图片素材,找3D模型素材就来3D溜溜网。

2015年8月3日 · 立式磨粉机简称立磨,又称立磨机,立磨粉机,立磨是目前世界上先进的粉磨设备。立磨图是立磨结构图的简称,立磨图包括整个立磨生产线配件的安装图示,如立磨主机结构图,立磨减速机结构图,立磨护套图片,立磨图纸。按所磨物料分为矿渣立磨图和水泥立磨图等。

行星式球磨机示意图怎么画,cry:谁有QMBP行星式球磨机的说明书?从CD1到CD13都代表些什么啊?我这快疯了。 请问你们所使用的南京大学仪器厂的球磨机效果怎么样.你是指。

气流筛粉机 摈弃了传统的重力势能作业原理,开辟了载流体动能做功的筛理新途径,它是在密闭状态下利用高速气流做载体,使充分扩散的粉料微粒以足够大的动能向筛网喷射, 达到快速分级之目的。 微细粉物料经进料斗流人进料斗口,立即扩散并与空气混合成雾状, 经旋转风轮的作 .

2017年9月6日 · 按照指导教师的要求,本设计给定的要求是:磨辊规格为Φ250×1000;磨辊排列方式为平置;按照目前磨粉机的结构,快慢辊间采用加长齿轮减速箱传动;自动调节料门;机械 .

振动筛是利用 振子 激振所产生的往复旋型振动而工作的。 振子的上旋转重锤使 筛面 产生平面回旋振动,而下旋转重锤则使筛面产生锥面回转振动,其联合作用的效果则使筛面产生复旋型振动。 其振动轨迹是一复杂的空间曲线。该曲线在水平面投影为一圆形,而在垂直面上的投影为一椭圆形。

2021年2月1日 · 本机的结构简单、紧凑,实用性强,装、拆、检修方便,而且各个结构的尺寸都比较校本机磨辊内平置,其喂料性能好;喂料流可直接进入粉碎区,并便于操作人员观察和调整 .

2022年12月30日 · 水洗高岭土可以用研磨磨粉机粉碎吗?青岛优明科粉体机械用实验数据说话,我们建有专门的实验室车间,实验室内配备研磨磨粉机,可满足各种工况下用研磨磨粉机对水洗高岭土进行粉碎实验。

烷烃(wán tīng)是一类有机化合物,分子中的碳原子都以碳碳单键相连,其余的价键都与氢结合而成的化合物,分为环烷烃和链烷烃两类。链烷烃的通式为CnH2n+2,环烷烃的通式为CnH2n,是最简单的一类有机化合物。烷烃是有机化合物的母体,自然界中天然气、石油的主要成分均为烷烃。烷 .

2011年11月17日 · 铁矿石的加工过程 矿山机械 褐铁矿生产线褐铁矿石加工设备销售热线高铝褐铁矿石铁铝分离工艺,将褐铁矿石破碎文献内容包含配方比例生产工艺构造原理结构示意图等信息,具体详情欢迎咨询。

雷蒙磨又称 雷蒙磨粉机,英文全称:Raymond mill。它适用各种矿粉制备、煤粉制备,比如生料矿、石膏矿、煤炭等材料的细粉加工。雷蒙磨、雷蒙磨粉机、高效雷蒙磨、高压旋辊磨。

2021年5月23日 · 2、磨粉机的磨辊装置使用时间超过500小时左右重新更换磨辊时,对辊套内的各滚动轴承必须进行清洗,对损坏件应及时更换,加油工具可用手动加油泵。3、雷蒙磨粉机在使用过程当中,应有固定人员负责看管,操作人员必须具备一定的技术水平。

2017年2月25日 · 用螺栓将磨粉机,电动机紧固在机架相对应的位置上,用A型三角皮带连接磨粉机与电动机的V带轮,并用手转动皮带轮,检查其张紧程度,太松和太紧时调整电动机的距离。 .

2018年8月20日 · 磨粉机结构示意图磨粉机工作原理放在料斗上的物料经过调量板的调节落入机座内,然后由螺旋推进器把物料剪切 /输送到动、静磨片之间。 物料在两磨片之间再次剪切 /研 .

mgs4766双进双出磨煤机mgs4772双进双出磨煤机mgs5072双进双出磨煤机粉磨设备水泥磨原料磨高细磨陶瓷磨φ×φ×球磨机各350元φ×。 4台电动葫芦小车及控制装 .

1ZGM113G型中速辊式磨煤机使用和维护说明书篇磨煤机使用和操作说明图1―2磨煤机"沸腾区"示意图ZGM113G型磨煤机采用鼠笼型异步电动机驱动,通过立式伞齿磨煤机工作原理受理图 图1―1磨煤机加载传递系统"受力状态图"图1―2磨煤机"沸腾区"示意图 2:磨