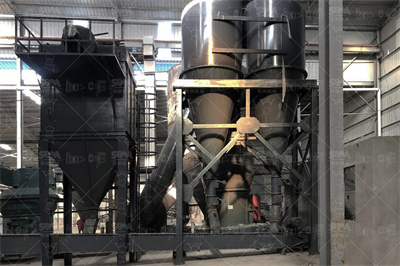

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

北京泰来华顿低温设备有限公司招聘铆工,北京个人发布职位,月薪面议.若邻网提供全的机械设备招聘信息,铆工相关的职位信息.以及更多北京电焊工铆焊工招聘.

2022年9月20日 · 铆接机主要靠旋转与压力完成装配,主要应用于需铆钉(中空铆钉、空心铆钉、实心铆钉等)铆合之场合,常见的有气动、油压和电动,单头及双头等规格型号。

2019年5月6日 · 封面文章机器人钻铆系统研究现状及发展趋势中航工业北京航空制造工程研究所,杜兆才,姚艳彬,王,健工业机器人具有成本低,灵活性高,安装空间小及自动化程度高等优点,对工件的适应性好,且可以通过扩展轴长距离移动,能完成多个区域的钻铆,而无需移动工件

2024年7月8日 · 北京长宏建翔科技发展有限公司也是北京唯一一家生产超声波焊接设备的厂家,公司品牌为:"长翔"工厂坐落在北京风景秀丽、交通便利的门头沟区石龙工业区。

2009年4月29日 · 德国宝捷公司研制了一种用于机器人的自动钻铆末端执行器,并且在设计中考虑了符合人体工学的装卸流程 [4] 。近年来,国内各大航空航天企业也与北京航空航天大学、浙江大学及南京航空航天大学等高校合作研制了运用于不同加工对象的钻铆末端执行器 [5] 。

①铸铁机身结构强,具备所有优点及铆合能力强。 ②两段式高低调整,精确度高,中心不会偏移。 ③铆钉成型力小,不破坏原有表面,铆钉铆后不易弯。 ④铆压时产品受力均匀,成型平整规 .

2015年2月2日 · 北京航空航天大学和沈阳飞机T业( 集团) 有限公司联合研制的机器人自动钻孑L系统具备视觉检测系统。可对制孔过程进行监测【7I。浙江大学研制了一套双机器人协同自动钻铆系统懈I。双机器人协同自动钻铆系统的装配对象为大型飞机机身壁板的万方数据

上海交通大学和上海拓璞数控科技公司开发了一套双工业机器人协 作自动钻铆系统,如图5所示,主机 器人末端装有钻铆执行器,辅助机 器人末端装有顶铁和激光位移传感 器。 该系统在主机器人钻铆端可以 检测铆钉的插入状态,在辅助机器 人顶铁 ...

2017年6月8日 · GEMCOR 机器人自动钻铆系统采用双编码器与视觉再同步技术提高机器人运动精度,从而满足飞机机身、登机门等飞机部件的自动钻铆装配。 2 EI公司 EI 公司成立于1986 年,以低压电磁铆接技术为核心,研制了一系列的自动钻铆系统,并已广泛运用在飞机装配中。

2018年5月16日 · 产品涉及领域广泛,有铆接机、旋铆机、铆钉机,主要适用于汽配产品的铆钉铆接作业、电子仪表件及其他各类仪表件的铆合、金属及非... 上海齐浦机械制造有限公司 位于上海黄浦江南岸奉贤区。 临近于"箱包工业城"奉城。距320国道7公里 ...

2015年9月25日 · 团)有限公司联合研制的机器人自动钻孔系统具备视觉检测系统,可对制孔过程进行监测。浙江大学研制了一套双机器人协同自动钻铆系统。双机器人协同自动钻铆系统的装配对象为 大型飞机机身壁板的蒙皮、长桁、钣金框以及用来连接钣金框与蒙皮的补偿角片。

2012年3月1日 · 深圳市翼鹏机械有限公司是国内一家专业、专注——开发、生产以及销售压铆机的厂家,客户遍布全国各地。 完善的、高水平的科研开发系统 公司拥有完善的、高水平的科研开发系统。

2024年2月14日 · 武汉优诚机械有限公司是一家集研发、生产、销售为一体的铆接自动化设备生产企业。 公司拥有多名铆接行业近二十年经验的技术工程师,技术实力雄厚,经验丰富。 武汉 .

双头旋铆机品牌/图片/价格 双头旋铆机品牌精选大全,品质商家,实力商家,进口商家,微商微店一件代发,阿里巴巴为您找到231个有实力的双头旋铆机品牌厂家,还包括价格,高清大图, .

北京双聚机械设备有限公司成立于2012年03月12日,位于北京市朝阳区北辰东路8号16号楼(E座)14层1408室,目前处于开业状态,经营范围包括销售机械设备及配件;技术咨询服务;机械 .

2025年1月26日 · 严重制约了中国制造业的转型升级。由北京华航唯实机器人公司牵头、北京 ... 飞机壁板钻铆实验研究,采用移动式AGV和双 机器人自动钻铆系统 ...

2015年5月30日 · 瑞典Novator公司开发了机器人轨迹制孔系统(Orbital ED100)。2009年,德国宝捷为欧直公司研发一种用于飞机货舱门制孔的机器人装配系统[12],如图1所示。意大利BC公司设计了双机器人自动钻铆系统,用于波音787机尾部件的自动钻铆和涂胶。

采用"六自由度机器人+多功能末端执行器"的构型,可集成六自由度定位、叠层压紧、法向找正、自动钻孔锪窝、自动除屑、基准孔找正、自动送钉、自动铆接等功能,配套界面友好的上位机及离线编程软件,用于航空航天部组件的自动钻锪和铆接装配。

厦门锋元机器人有限公司是新能源车轻量化零部件焊接机器人及产线集成领军企业(系中国制造隐形冠军入选企业),公司专注铝焊服务型制造,陆续攻克铝材、高强钢焊接工艺难题,为客户提供最具性价比的智能产线,积累了近千台套自动化焊接案例。

自动双铆 铆钉机五金工件自动送钉设备头盔安全帽礼盒打实心铆钉机 恒鹰 品牌 ... 东莞市鑫丰成机械有限公司 1 年 多款气动旋铆机转盘式多工位液压旋铆机脚轮支架插杆轴自动铆钉机 ...

2017年5月15日 · 美国GEMCOR公司研制的有关机器人用于钻铆工作的系统,应用双机器人实现对加工部件的调姿,再配合C型钻铆机,实现飞机部件的钻铆。 目前,国外自动钻铆的研究向机器人、柔性工艺装备、全自动钻铆机并配合激光测量等组成柔性自动化装配系统方向发展[5]。

意大利BC公司设计了双机器人自动钻铆系统,用于波音787机尾部件的自动钻铆和涂胶。巴西航空技术学院研制了双机器人铆接系统[13],A380及A320系列机翼壁板,波音787机身框架、波音747地板、波音737系列大梁、F16复合材料垂尾壁板及C130飞机梁腹板 ...

诠能五金机械有限公司铆钉机、旋铆机、鸡眼机、压铆机、钮扣机、撞钉机、五爪扣铆合机、塑钢扣铆合机、油压裁断机、冲孔机、切带机、分条机、烫金机、削皮机、上糊机、上胶机、裁铝 .

摘要: 自动钻铆技术极大地提高了飞机的装配效率,保证装配质量以及飞机使用寿命.双机器人钻铆系统以其自身独特优点,成为自动钻铆技术领域的重要发展方向.本文以某国防重大专项—一双机器人联合钻铆试验系统为研究背景,对机器人铆接试验中存在的问题进行分析研究,验证了双机器人协 .

上海灿异机电科技有限公司是一家专业从事高精度径向铆接机/高精度旋铆机/Canyi智能数控铆接系统研发生产的科技型企业。