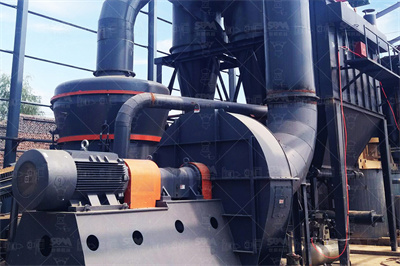

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2022年6月18日 · 为处理好矿山开采与生态环境的矛盾,彭泽县"疏""堵"结合,彭泽县全面落实矿山企业"缩点、减量、限期、复绿"等措施,探索环保化、园林化、现代化、和谐化、工艺化的"五 .

2025年4月21日 · 爱企查为您提供彭泽县臻融建材集团有限公司的企业信息查询服务,查询彭泽县臻融建材集团有限公司工商注册信息、电话邮箱、公司地址、经营风险、控股持股、发展动态、财务状况、股东法人高管、商标专利、品牌项目、竞品信息、融资历史、变更记录、法律诉讼、招投标、招聘、新闻资讯等 ...

2024年2月6日 · 江西九江南方水泥有限公司前身为九江兰丰水泥有限公司,创建于 2003 年10 月,注册资本18000万元,住所位于彭泽县龙城镇茅店村。 公司于 2009 年合并到江西南方水泥 .

2025年4月21日 · 丰城市和泰矿产有限公司是专业从事矿山 开发,石灰石开采运输、破碎加工及销售,提供矿山服务的综合性矿产资源公司 ... 江西省九江市彭泽县南方水泥 乐观石灰石矿 贵州省锦屏县和泰水泥大坪坡石灰石矿 江西省吉安市永丰县南方水泥石灰石 ...

2023年1月9日 · 1月4日至6日,江西省厅矿保处处长伍锡论一行来瑞昌市、彭泽县、庐山市和德安县开展绿色矿山复核工作。九江市自然资源局党委委员、副局长李英富,瑞昌市、彭泽县等政府分管领导陪同。

2024年9月9日 · 位于九江市彭泽县,法定代表人为王付良,目前处于存续 状态。公司人员规模:200299人,参保人数:254人,注册资本:18500万元人民币,实缴资本:18000万元人民币。通过企查查大数据分析,江西九江南方水泥有限公司共分支机构1家,参与招投标 ...

2023年4月27日 · 根据《江西省绿色矿山管理办法(试行)》(赣府厅发〔 2 021 〕 3 8 号)规定,德安县永飞矿业有限公司萤石矿等 9 家矿山企业,经第 2 次厅长办公会审议通过,拟纳入 2 023 年度第一批省级绿色矿山名录。 现将 2 023 年度第一批省级绿色矿山拟遴选推荐名单进行公示,公示期自发布之日起 7个工作日。

由于此网站的设置,我们无法提供该页面的具体描述。

2024年1月16日 · 近年来,彭泽县始终将绿色矿业理念与实践贯穿于矿产资源开发利用全过程,围绕"打造长江经济带绿色矿业发展示范区"目标要求,按照环保化、园林化、工艺化、数智化、 .

2017年2月23日 · 江西彭泽矿山物料运输专用线建设项目日前签约启动,运输线长60公里左右,配备两个5000吨级码头。 江西省九江市周边砂石骨料产业聚集,加上毗邻黄金水道,巨大的产能大部分依靠公路运输,车辆超载、超速和洒泼对公路破坏十分严重,矿产品运输已经成为制约本地区矿产企业经济发展的瓶颈。

2017年2月23日 · 江西彭泽矿山物料运输专用线建设项目日前签约启动,运输线长60公里左右,配备两个5000 ... 2月21日上午,彭泽县矿山 物料运输专用线建设项目签约仪式成功举行,彭泽县县长邵九思与安徽盛运环保(集团)股份有限公司总裁王仕民签订了《项目 ...

2020年6月17日 · 绿水青山就是金山银山,为创建生态彭泽,共建美丽家园,实现高质量跨越式发展,彭泽县一手抓国家级绿色矿山创建,一手抓矿山产业转型。 不少矿山企业走上转型升级之 .

2019年12月30日 · 彭泽县矿业权出让网上拍卖公告 赣国土资网交矿[2019]G004号 根据《江西省土地使用权和矿业权统一网上交易管理办法》等有关规定,受彭泽县自然资源局委托,九江市国土资源交易中心以网上拍卖方式出让下列矿业权。

2003年10月10日 · 江西省九江市彭泽县 龙城镇茅店村 查看详情 附近企业 简介: 江西九江南方水泥有限公司成立于,法定代表人为王付良,注册资本为18500 万人民币,统一社会信用代码为,当前处于存续状态。企业注册地址位于江西省九江市 ...

2025年4月23日 · 简介: 1、基本情况 江西九江南方水泥有限公司是一家国有企业、小微企业,该公司成立于2003年10月10日,位于江西省九江市彭泽县龙城镇茅店村,目前处于开业状态,经营范围包括许可项目:水泥生产,矿产资源(非煤矿山)开采,发电业务、输电业务、供(配)电业务(依法须经批准的项目,经 ...

2020年11月3日 · 肖乾初经理向李总等人详细汇报了本项目的开采方案、安全环保工作计划、绿色矿山创建工作、项目安全管理分级管控计划等。 李总对项目取得的成绩给予了肯定,对开采方案等进行了评审;对下一步工作强调以下三点: 1、要求管理人员定期进行安全检查,及时进行隐患排查,围绕"2+1"体系做好安全工作,消除隐患,加强员工 教育培训力度,提高全员安全意识及 .

2024年11月13日 · 彭泽县三畈矿区建筑石料用灰岩矿开发建设项目重大变动环评报告书.doc,PAGE 建设项目环境影响报告表 (污染影响类) 项目名称:九江恒晋新材料集团有限公司彭泽县三畈矿区建筑石料用灰岩矿开发建设项目重大变动 建设单位(盖章): 九江恒晋新材料集团有限公司 编制日期: 2024年8月 中华人民 ...

江西九江南方水泥有限公司成立于,位于江西省九江市彭泽县龙城镇茅店村,经营范围为许可项目:水泥生产,矿产资源(非煤矿山)开采,发电业务、输电业务、供(配)电业务(依法须经批准的项目.

2023年12月8日 · 另外,恒晋矿业一期年产2000万吨砂石项目即将投产(规划3500万吨);亚东水泥年产千万吨级砂石项目预计明年中旬投产。12月5日,中铁四局旗下公司在彭泽县竞得一宗储量达亿吨、年产600万吨的大型砂石矿山,江西省砂石大型矿山越来越多。

2018年10月24日 · 绿色矿山的"彭泽模式"——"一矿一景",矿山园林化 近年来,为有效保护生态环境,科学利用好矿山,彭泽县拿出了实实在在的做法,在全面整治违法采矿工作中,坚持绿色发展之路,在适度保障市场需求且满足环境保护要求的前提下,控制采矿权的最低数量,有序退出全部探矿权,实现资源 ...

大江网/大江新闻客户端讯 王武学、马志坚报道:近年来,彭泽县始终将绿色矿业理念与实践贯穿于矿产资源开发利用全过程,围绕"打造长江经济带绿色矿业发展示范区"目标要求,按照环保 .

2022年12月24日 · 江西彭泽,长江沿线矿产资源最为丰富的地区之一,立足于此,江西九江南方水泥有限公司积极响应彭泽县政府打造"绿色矿山"号召,以变革赋能环境,用成绩与彭泽对话,走出了一条共建绿水青山的发展之路。 三、创意阐述专题片表现形式以 ...

2024年1月23日 · 坚持把发展矿区循环经济作为实现矿业高质量发展的重要手段,以绿色开发综合利用、科技创新数字管理为途径,加强开采后碎矿、选矿、废弃物的循环利用,节约高效利用 .

2023年6月19日 · 本项目选址于九江市彭泽县杨梓镇现有矿山及骨料生产线旁边,减量置换建设一条4800t/d新型干法熟料水泥生产线,同步配套建设9MW纯低温余热发电系统。

2022年10月19日 · 该矿是彭泽县拟新设出让的新矿山,开采矿种为建筑石料用灰岩,拟设生产规模 600万吨/年。开采年限: 22年;资源储量: 万吨;矿区目前在办理前期设置手续,矿区目前遗留有原先老矿山废弃采坑。矿区面积公顷,拟开采标高:+151

2023年8月16日 · 为积极践行"山水林田湖草沙一体化"生态修复理念,借力打造长江最美岸线契机,把废弃矿山生态修复列为"创建生态彭泽、共建美丽家园"建设的重要内容,提出了"政府指导 .