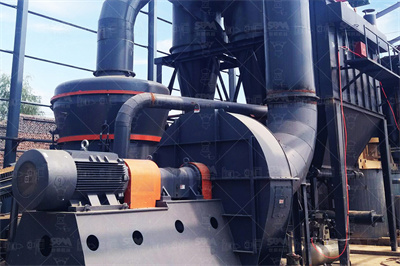

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2025年3月27日 · 南京市浦口区普俊盛机械厂成立于2006年11月22日,位于南京市浦口区汤泉街道工业集中区,目前处于开业状态,经营范围包括通用机械设备加工、销售;体育器材制造、销 .

阿里巴巴为您找到1020条关于南京小型机械加工厂生产商的工商注册年份、员工人数、年营业额、信用记录、主营产品、相关南京小型机械加工厂产品的供求信息、交易记录等企业详情。

1979年9月25日 · 企查查为您提供江苏惠浦机械集团有限公司知识产权综合查询,助您了解江苏惠浦机械集团有限公司商标注册、专利信息、著作权登记信息、域名、资质认证等,全面掌握威江苏惠浦机械集团有限公司拥有知识产权的数量和质量。

2022年6月30日 · 简介: 南京航浦机械科技有限公司,成立于2016年,位于江苏省南京市,是一家以从事金属制品业为主的企业。 企业注册资本3000万人民币,实缴资本3000万人民币。通过天眼查大数据分析,南京航浦机械科技有限公司参与招投标项目9次;知识产权 ...

江苏惠浦机械集团有限公司公司详细介绍:南京第四机床厂始建于1960年,是原机械部重点定点厂家之一,有四十余年生产摇臂钻床和,联 系 人:王森 机床商务网

2024年8月10日 · 南京浦园机械制造有限公司的地址为南京市浦口区桥林经济开发区春羽路9号,位于江苏南京浦口区,属于江苏省南京浦口区江浦街道,江苏省南京浦口区高旺社区,江苏南京 .

南京航浦机械科技有限公司 时间: 来源:资产经营有限公司 点击: 347 公司依托南京航空航天大学江苏省精密与微细制造技术重点实验室的技术力量,由南京航空航天大学和南京市浦口区人民政府合资共建,针对高端制造与装备领域中的 ...

2022年11月5日 · 南京中浦食品机械制造有限公司,位于六朝古都、江苏省会南京,南京市浦口区桥林街道丹桂路46号,于2005年11月23日在南京成立。公司资金充裕,注册资本500万元人民币,在魏百树带领下,中浦食品机械已经为客户提供了19年优质的服务,公司主要提供食品生产机械设备制造、安装、销售;食品生产 ...

2025年1月27日 · 简介: 1、基本情况 南京中浦食品机械制造有限公司是一家小微企业,该公司成立于2005年11月23日,位于南京市浦口区桥林街道丹桂路46号,目前处于开业状态,经营范围包括食品生产机械设备制造、安装、销售;食品生产、销售。

22 小时之前 · 南京浦禧自动化科技有限公司是⼀家成⽴于2018年07月26日的有限责任公司,属于以从事批发和零售业为主的企业。位于南京市浦口区,法定代表人为安龙吉,目前处于在业状态。

2023年9月20日 · 注册地址:南京市 浦口区桥林街道步月路 29 号 12 幢 84 号 注册日期: 2016 年 5 月 27 日 注册资本: 3000 万元 经营范围:机械科技研发;金属工具、金属加工机械、物料搬运设备、非金属加工专用设备、通用机械设备零部件研发、设计、制造 ...

2025年2月27日 · 简介: 江苏惠浦机械集团有限公司成立于,法定代表人为刘锴,注册资本为3000 万人民币,统一社会信用代码为J,当前处于存续状态。 企业注册地址位于南京浦口区石佛寺,所属行业为金属加工机械制造,经营范围 ...

2024年9月14日 · 简介: 1、基本情况 江苏惠浦机械集团有限公司是一家国有企业,是方源集团旗下的企业。该公司成立于1979年09月25日,位于南京浦口区石佛寺,目前处于开业状态,经营范围包括金属切削机床及配件、传动轴总成、汽车零配件、摩托车零配件制造、销售,金属切削机床、汽车维修,电子产品、服装 ...

南京浦园食品机械制造有限公司,位于六朝古都、江苏省会南京,中国 江苏 南京市 浦口浦珠路,浦园食品机械在开业后蓬勃发展。 公司主要提供食品机械, 欢迎各界朋友莅临参观、指导 .

BOSS直聘为求职者提供2025年南京市浦口区照浦机械厂招聘,更有南京市浦口区照浦机械厂的公司简介、公司地址、产品介绍、公司环境、CEO高管资料以及在线的BOSS们,南京市浦口区 .

南京市浦口区安利五金机械厂是⼀家成⽴于2013年06月06日的个体工商户,属于以从事制造业为主的企业。位于南京市浦口区,经营者为谷祖卿,目前处于存续状态。公司人员规模:少于50人。

3 天之前 · 江苏惠浦机械集团有限公司(曾用名:江苏省南京第四机床厂)是⼀家成⽴于1979年09月25日的有限责任公司,也是江苏方源集团旗下企业,属于以从事制造业为主的企业。位于南京市浦口区,法定代表人为刘锴,目前处于存续状态。

2015年6月8日 · 成 公司在从事管桩制造的同时,大力发展多元经济,不断进行转型升级,已收购兼并了金台造纸厂、水利机械厂、浦南内河港等4家企业,其中1家军工企业,2家国有企业和1家 .

2025年4月23日 · 南京航浦机械科技有限公司是一家科技型中小企业(2024)、小微企业,该公司成立于2016年05月27日,位于南京市浦口区桥林街道步月路29号12幢84号,目前处于开业状态,经营范围包括机械科技研发;金属工具、金属加工机械、物料搬运设备、非金属加工专用

主营产品: 机械设备、数控机床、机电设备、自动化成套控制装置系统、仪器仪表、刀具、量具、五金销售;机械设备维修、... 主营产品: 一、非金属类(无石棉压缩板材,无石棉压缩板材 .

南京浦园机械制造有限公司成立于2003年02月10日,注册地位于南京市浦口区桥林经济开发区春羽路9号,法定代表人为魏代康,注册资本为3000万元。 公司对外投资2家公司。

2003年5月21日 · 企查查为您提供南京市浦口区照浦机械厂的最新工商信息、公司简介、公司地址、电话号码、招聘信息、信用信息、财务信息、法律诉讼等多维度详细信息查询,让您对南京 .

南京浦联机械厂,办公室地址位于六朝古都、江苏省会南京,金汤街77号,于2002年08月16日在南京成立,我工厂主要提供机车车辆配件加工、销售 我们致力于提供的生产解决方案,期待与 .

2024年9月22日 · 启信宝为您提供南京市浦口区照浦机械厂的相关企业查询服务,包括工商信息、公司地址、公司电话、招聘信息,股权信息等,还提供了南京市浦口区照浦机械厂的企业信用 .

2024年9月28日 · 简介: 江苏惠浦机械集团有限公司(曾用名:江苏省南京第四机床厂)是⼀家成⽴于1979年09月25日的有限责任公司,也是江苏方源集团旗下企业,属于以从事制造业为主的企业。 位于南京市浦口区,法定代表人为刘锴,目前处于存续状态。公司人员规模:人,参保人数:1299人,注册资本:3000 ...

2025年4月23日 · 简介: 1、基本情况 江苏惠浦机械集团有限公司是一家国有企业,是方源集团旗下的企业。该公司成立于1979年09月25日,位于南京浦口区石佛寺,目前处于开业状态,经营范围包括金属切削机床及配件、传动轴总成、汽车零配件、摩托车零配件制造、销售,金属切削机床、汽车维修,电子产品、服装 ...