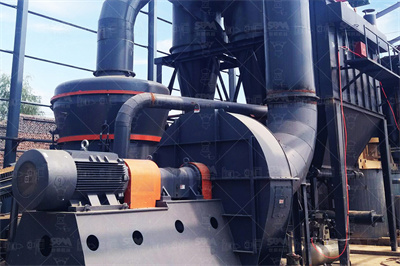

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2017年10月31日 · 黄石矿博园 黄石矿物晶体奇石文化博览园(简称黄石矿博园)建成于2016年9月,位于黄石市大冶湖生态新区核心区域。项目占地万平方米,总建筑面积10万平方米,其中地上建筑面积万平方米,地下建筑面积万平方米。

2018年8月17日 · 在黄石大冶 的铜绿山上,有一种野花叫铜草花。商周时期的先民在没有先进的勘矿技术情况下,逐渐发现了铜草花与铜矿间的微妙联系,用这个天然寻矿"路标"发现了铜绿山上的矿石。黄石三千年矿冶古都的历史也由此拉开帷幕 ...

由于此网站的设置,我们无法提供该页面的具体描述。

以上是顺企网黄石大冶市黄页企业单位名录,有包括湖北中柱古建园林有限公司、黄石大冶宗谱文化科技中心、湖北日斗金节能保温建材有限公司、湖北古韵园林景观有限公司等在内的100529家黄石大冶市厂家、黄石大冶市供应商批发商的介绍和地址电话法人代表和联系电话等信息,一共分 .

2024年8月21日 · 在黄石,诞生了中国第一家用机器开采的大型露天铁矿——大冶铁矿,建成了湖北第一条铁路——大冶铁路,分布着远东第一水泥厂、中南地区第一大电厂、湖北省最大的煤炭基地、长江最大的运矿港口等,时至今日,大冶铁矿、大冶特钢、华新水泥等多个百年老

2019年12月9日 · 附件: 黄石市 安全生产标准化三级达标企业名单 2019 年 12 月 4 日 附件: 黄石市非煤矿山安全生产标准化 三级达标企业名单( 7 家) 1、大冶市天石粉体材料有限公司方解石矿 2、大冶市兴红矿业有限公司选矿厂 3、湖北营润矿山建设有限公司驻兴红项目部

2016年7月19日 · 17日,国土资源部史志办专职副主任张泓咨询多位专家后明确称, 这是国内至今开采出的体量最大、品质最好的透明石膏。 这块石膏是去年底,矿工从一整片透明石膏矿中开 .

黄石 孔雀石,。孔雀石古称石绿,,,放射状可作为天然颜料,且颜色鲜亮久不褪色,皮壳状可作观赏石或琢制工艺品 ... 大冶铜绿山矿是国内著名的孔雀石产地,以质地好, 颜色鲜艳而闻名遐迩。以孔雀石为原料可加工串珠、手链、佛珠、耳丁、项链 ...

由于此网站的设置,我们无法提供该页面的具体描述。

2025年1月17日 · 2018年4月,黄石大冶湖国家级高新区正式挂牌成立,成为全市经济发展主战场、创新驱动主引擎,正倾力打造鄂东科创高地、先进制造标杆、绿色低碳园区。 推进中国式现代 .

2024年4月17日 · 受黄石成美建材有限公司的委托,征得黄石市国土资源局的同意,湖北三大环境勘查有限公司于2014年9月20日至10月2日,开展了对湖北省大冶市阴山沟矿区水泥用石灰岩矿矿产资源储量核实工作,并提交了《湖北省大冶市阴山沟矿区水泥用石灰岩矿资源储量核实

2019年8月27日 · 重建后的大冶铁矿,迅速形成年生产原矿440万吨、年选矿430万吨的综合生产能力,可生产铁精矿、铜精矿、钴硫精矿、块矿、粉矿等矿石产品,可直接和间接回收铁、铜、硫、钴、黄金、白银等金属和非金属元素,成为全国十大铁矿生产基地之一。

2024年5月7日 · 红星石膏矿矿体位于接触带附近,矿体主要受斑状闪长岩与大理岩接触带构造控制,矿体在剖面上呈透镜状、囊状,矿体因受接触带控制,矿层(矿体)总体产状与接触带产状 .

由于此网站的设置,我们无法提供该页面的具体描述。

2021年4月30日 · 大冶铁矿实习报告共6篇 第1篇:大冶铁矿实报告大冶铁矿实报告大冶矿区位于xx省黄石市西部铁山区,大冶矿区共由6个大矿体组成,自东向西依次为尖山狮子山象鼻山尖林山龙洞和铁门坎,储量比较丰富。大冶铁矿建成了亚洲第一的硬岩复垦基地,昔日的废石场已

由于此网站的设置,我们无法提供该页面的具体描述。

2020年1月16日 · 岩体规模:大岩体。二、区域成矿地质特征 大冶式铁矿中几个典型矿床的成矿地质特征如下。(一)铁山铁(铜)矿床 侵入岩:正长闪长岩、细斑石英正长闪长玢岩或黑云母透辉石闪长岩。围岩:大冶组及嘉陵江组。成矿时代:K-Ar年龄:矿石中金云母132

2022年6月17日 · 27 黄石 大冶市 大冶市天石粉体材料 有限公司方解石矿 5 方解石 150 平硐 / 余光 华 停产 大冶市 应急管 理局 熊海 刚 副局长 大冶 市 乐晗 副市长 金湖街 道 门超 党工委员、副主任 28 黄石 大冶市 大冶市永

2010年1月1日 · 这里是大冶市都鑫摩擦粉体有限公司在顺企网黄石黄页的介绍页,位于大冶市金山店镇新楼村(新楼工业园区),营业范围有硫化锑;氧化铬绿;煅烧石油焦;铬铁矿;氧化铝;黄铜矿;沉淀硫酸钡;锆英砂;铁粉;人造石墨,联系电话为:

中国粉体网2月26日讯 近日,在黄石市政府服务大冶有色金属公司工作专班、黄石市国土资源局、大冶市政府的共同鉴证下,大冶有色金属公司铜绿山矿与周边的大冶市喻家山铜矿、大冶市泉塘铜铁矿、大冶市泉塘三号坝铜铁矿3家矿山签订矿产资源整合协议,标志有色公司铜绿山矿区整合工 .

2023年7月15日 · 黄石市是我国重要的有色金属和冶金原料基地,现已发现各类矿产65种,已查明资源储量的矿产30种,查明矿区共 308处。 截至2023年6月底,我市共有采矿权170家,其 .

中国粉体网石膏矿专场是业内最全的石膏矿产品交易平台,您可以查看海量精选的 石膏矿 产品信息,还可以浏览石膏矿公司信息,石膏矿种类很多,本专场会为您提供全方位的解决方案!

由于此网站的设置,我们无法提供该页面的具体描述。

2018年6月6日 · 80年的露天开采,让湖北黄石的大冶铁矿挖出了"亚洲第一采坑"。开采的废石被倒于周边,日积月累,形成了总面积相当于9 ... 大冶铁矿矿志内的一幅彩照记录了植树的一幕。照片上,约30 名职工身着统一工服,头戴安全帽,手持铁锨,三两人 ...

2023年12月28日 · 针对开采环境复杂、作业地点分散、生产流程不连续,导致在凿岩、装药、出矿、溜井放矿、运输等采矿重点作业环节,设备分散、动态性强、作业环境恶劣、安全隐患突出 .