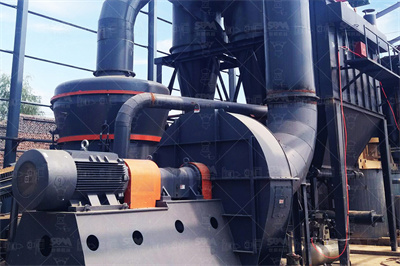

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2015年8月16日 · 1 年产30万吨立窑水泥生产线 设 计 方 案 南京苏材重型机械有限公司 二0一一年十二月二十三日 2 一、生产工艺 建设规模及生产方法 建设规模: 建设一条日产600吨 .

2011年7月20日 · 中国水泥工业生产方式主要有干法、湿法,半干法(立窑、立波尔窑)和新型干法等形式,而金隅琉水却经历了除湿法生产之外的所有生产形式,同时还兼有我国水泥工业不 .

2025年4月17日 · 石灰立窑,顾名思义是用于烧制石灰的、外形竖立的窑。郑矿机器生产的现代新技术石灰立窑是具有环保、节能功能和机械化 、自动化程度较高的现代化石灰窑。它因采用了 .

江苏鹏飞集团拥有年机械加工能力30万吨的机械装备制造加工基地,具备直径13 m立车、直径12m、40模滚齿加工能力,退火炉8*20m,最大起吊能力400吨,满足φ10m以下回转窑、球磨 .

2019年4月9日 · 利用不低于 2000 吨/日(含)新型干法水泥窑或不低于6000 万块/年(含)新型烧结砖瓦生产线协同处置废弃物;新型干法水泥窑生产特种水泥工艺技术及产品的研发与应用; .

2017年8月22日 · 通过了ISO9001:2008质量管理体系认证,是国内专业制造大型窑磨的主要供应商,具有50余年的设备制造经验,已形成了完善的设计开发、产品制造、市场推广、设备安装 .

一、设备介绍:水泥立磨采用了新一代的水泥粉磨技术,具有生产工艺系统流程简单、单位电耗低、水泥产品质量稳定以及操作方便等诸多优点,已经在水泥熟料粉磨领域迅速发展起来。富兰 .

2008年7月11日 · 这条立波尔窑恢复生产后累计生产干山牌水泥1865万吨.在当时,的确为新中国的经济建设做出了突出贡献。 从1941年到2008年,67年的风风雨雨.立波尔窑见证了中国水 .

2022年10月21日 · 立波尔窑1930年德国人立列普(Lellep)首创的由一台回转窑和一台加热机组成的煅 烧系统。 它是把干生料粉加少量水成球,喂到窑尾加设的加热机(如回转篦式加热机) .

2024年4月23日 · 1958年,全国工农业生产正处在"大跃进"时期,福建省人民委员会召开会议决定,拟在永安市曹远镇坑边建设一座大型水泥厂,以满足本省经济建设和国防建设的需要。福建水 .

①干法水泥生产 工艺流程。将 原料 同时烘干并粉磨,或先烘干经粉磨成生料粉后喂入干法窑内煅烧成 熟料 的方法。 但也有将生料粉加入适量水制成 生料球,送入立波尔窑内煅烧成熟料的方 .

2008年7月9日 · 6月30日上午10时45分,随着指挥长的一声令下,已有67年历史的辽阳干山水泥有限责任公司立波尔窑生产线"寿终正寝",这也是全国最后一条立波尔窑生产线被拆除。 辽阳干 .

2013年12月24日 · 到目前为止,我国已经研制出具有自主知识产权的并成功应用在水泥工业的生料、煤粉、矿渣和水泥的粉磨作业中的各型立磨有:长城机械GRM立磨机、沈阳重型机械集团 .

2004年10月27日 · 中国在清末民初期间,延绵30多年时间里成立的这几个立窑水泥厂,它们都采用购自国外的技术 (尚处于初级阶段的立窑设备),其装、卸料都是人工作业,往往只是在操作技 .

2022年6月17日 · 年产200万吨水泥工艺设计.doc,目录年产200万吨水泥成品工段工艺设计 前言 水泥(英文名cement ... 1910年土立窑得到了改进,实现了立窑机械化连续生产。 1928年德国的 .

2020年8月3日 · 这条立波尔窑恢复生产后累计生产干山牌水泥1865万吨,在当时,的确为新中国的经济建设做出了突出贡献。 2008年这条全国最后一条立波尔窑生产线拆除。

2002年9月12日 · 2001年末,中国还有各类湿法窑200座,总生产能力5000万吨。随着煤炭行业结构调整的到位,煤炭价格逐渐趋于合理,湿法窑的竞争能力每况愈下,沿海地区的湿法窑企业 .

2018年6月22日 · 年产160万吨水泥厂业设计论文.doc,本科毕业设计说明书 年产160万吨熟料舜岳水泥厂设计—重点设计:水泥粉磨 THE PRODUCTION OF CLINKER PER YEAR MILLION .

2019年11月20日 · 中国混凝土与水泥制品协会 中国非金属矿 工业协会 中国砖瓦工业协会 中国石材协会 中国玻璃纤维工业协会 中国复合材料工业协会 ... 1、干法中空窑,水泥机立窑,立波尔 .

2011年12月6日 · 曾于1921年制造中国第一台烘干机,1922年制造我国第一套水泥旋窑,1958年制造我国第一台年产30万吨水泥立波尔窑,1962年制造我国第一台400×600mm鄂式破碎 .

2019年2月1日 · 1963年第一条φ×48m立波尔窑投产,日产水泥770吨,1965年2月第二条φ×56m立波尔窑投产,日产水泥1030吨,全场年产水泥60万吨。 ②正泰水泥公司,1960年 .

2020年10月9日 · 中国历史上共有9家立波尔窑水泥生产企业。 目前唯一没有被拆除的只有琉璃河一家(现北京金隅琉水环保科技有限公司)。 此生产线是世界以及中国水泥工业发展进程中的 .

2017年9月11日 · 日产熟料5000t预分解窑水泥厂窑尾工艺设计计算书.doc,摘 要 水泥生产的总体流程为:把大块的石灰石通过破碎设备与黄泥铁粉通过计量混合送入原料磨成一定的粒度的生 .

2008年2月22日 · 虽然习惯将现存的水泥制造技术分为回转窑和立窑两大类,但它们并不是相互分离的独立体系。经典水泥工艺教程将水泥的工艺过程概括为"两磨一烧",再次粉磨对两种水泥 .

年产20万吨水泥立窑生产,*集团现已建成年产500万吨水泥生产能力,与JL亚泰水泥有限公司并称东北地区两大水泥 劳动生产率低、产品质量不稳定、资源浪费和环境污染较严重的立窑水泥。 .

2023年5月22日 · 至此,永安水泥厂两套立波尔窑生产工艺线基本建成,形成了年产47万吨水泥的规模,跨入国家大中型水泥企业的行列。 3#窑基建 十一届三中全会以后,国家迎来了崭新发 .

2009年10月15日 · 在此阶段,建材部水泥局针对广大地方水泥(统称小水泥)企业存在的诸多问题进行了总结和整顿,适时推出由北京水泥工业设计院万吨立窑水泥厂,配备2台直径2×8米 .

人们对立窑水泥指责最多的是粉尘污染,其实这对现代化立窑技术来说是冤枉的,土立窑、一般机械化立窑由于工艺不完善,不能保证煅烧过程热工制度稳定,烧成看火岗位不得不采用甚至明 .