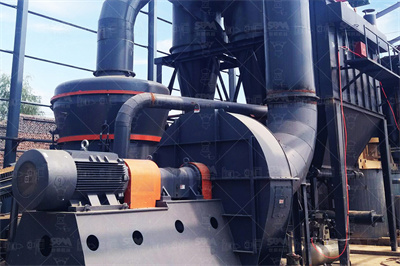

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2023年6月20日 · 报告摘要 报告目录 据贝哲斯咨询统计,2022 年全球粉磨机行业市场规模达到亿元(人民币),中国粉磨机市场规模达亿元。预计2028年全球粉磨机市场规模将达亿元,年期间年复合增长率(CAGR)为 %。

La bersistir拉比斯特咖啡机清洁粉全半自动清洁剂清洗冲煮头药粉除水垢粉磨豆机280g 清洁粉280g 0+条评论 La bersistir拉比斯特S70磨豆机电动意美式商用咖啡豆研磨粉碎机 黑色(74mm不锈钢刀盘 赛事指定 0+条评论 ...

2017年9月22日 · 2012年10月江苏鹏飞集团承建巴西INDÚSTRIA DE CIMENTOS DE ALAGOAS 公司年产60万吨水泥粉磨站,项目建设在巴西阿格拉斯,合同金额680万美元。鹏飞集团负责水泥粉磨站整条生产线建设,2015年8 月顺利投产。项目工程范围包括成套主机设备供货 ...

由于此网站的设置,我们无法提供该页面的具体描述。

随着 预分解窑 发展日趋完善,熟料生产热耗大幅度降低,而水泥生产综合电耗却长期居高不下。 20世纪80年代,人们重点关注粉磨技术的改进和突破。关注利用 挤压粉磨技术 代替冲击粉磨技术的研究,以提高粉磨功的利用率,降低水泥生产综合电耗。 因此,水泥粉磨技术创新,对于提高水 .

选择克洛诺斯雷蒙磨粉机,不仅意味着您将获得高效、精准的粉磨解决方案,更将体验到我们为客户提升价值、为企业发展惠及周边社区民众的真诚努力。

2016年3月19日 · 选粉机的作用是:将磨机粉磨到一定粒度的细粉分离出去成为合格产品,粗粉重新返回磨机进行再粉磨;并能防止细粉在磨内钻附研磨体引起缓冲作用,提高磨机的粉磨效率,调节颗粒组成,防止细粉不均匀现象,所以选粉机能够保证粉磨质量,提高磨机台时产量。

阿特拉斯MB1000破碎锤换型号105人咨询了报价询底价参数配置查看更多参数基本性能工作油量85130工作压力。 EDT2200A三角型系列爱德特破碎锤使用优化的设计方案,具备强劲冲击力,尽 .

由于此网站的设置,我们无法提供该页面的具体描述。

由于此网站的设置,我们无法提供该页面的具体描述。

2021年10月8日 · 编制说明 二期220万吨水泥粉磨生产线是集团实现可持续发展目标的重要举措,该生产线的建成投产对集团公司拓展市场增强社会效益具有重要的现实意义。项目按照先进的水泥粉磨工艺设计,充分体现环保节能理念,建成后将是一条新型的现代化粉磨生产线。

粉磨机品牌/图片/价格 粉磨机品牌精选大全,品质商家,实力商家,进口商家,微商微店一件代发,阿里巴巴为您找到85,630 ...

2021年6月12日 · 破碎机昆明销售 凯特gyp900惯性圆锥破碎机解图 破碎机PE500*700 上海破碎粉磨设备 鄂式破碎机500x750 l立轴破碎 ... 250X1200破碎机的处理量 在2000吨以上的煤矿破碎机 磨粉机50t/h200 胶带输送机1200作用 阿特拉斯mB2200破碎锤 y200le破碎机 矿用 超 ...

辊压机及挤压粉磨 技术的进展和实践中国水泥技术网 本文介绍了辊压机及挤压粉磨技术装备与工艺,如耐磨辊面的全套修复方案,挤压 .. 粉磨系统,是由两套带φ×开路球磨机的联合粉磨系统组成;由德国洪堡 ...

阿里巴巴1688为您优选2476条实验室粉磨机热销货源,包括实验室粉磨机厂家,品牌,高清大图,论坛热帖。 找,逛,买,挑实验室粉磨机,品质爆款货源批发价,上1688实验室粉磨机主题频道。

喷射粉磨机* 主要组成部分: 重锤式冲击部件、分级轮、风扇轮、环形空气入口管、产品出口管、螺旋给料机和转子轴等。 ... (2)特劳斯特型气流磨 粉碎部分采用逆向气流磨结构,分级部分则采用扁平式气流磨结构,因此它兼有二者的 ...

2012年2月,由FL独资成立的艾法史密斯机械(青岛)有限公司落户胶州,一期工程占地面积38,000平米,在青岛原有生产规模上扩大了三倍。主要生产:最新设计的日产熟料5500吨新型干法窑烧成系统,包含窑尾废气净化、预热器、分解炉、回转窑、燃烧器、喂煤称、篦冷机等。

2010年10月9日 · 在这一浪涛中,水泥粉磨节能技术得到了飞速发展,各种节能降耗的新型粉磨设备应运而生;FPP磨机就是其中最新的设备之一。 ... 据科学网电子杂志最新报道:由英国Novacem公司瓦拉斯普鲁斯牵头研制成功的绿色水泥,被评为2010 年最具潜力的 ...

2017年6月19日 · 喷射粉磨机* 主要组成部分: 重锤式冲击部件、分级轮、风扇轮、环形空气入口管、产品出口管、螺旋给料机和转子轴等。 ... (2)特劳斯特型气流磨 粉碎部分采用逆向气流磨结构,分级部分则采用扁平式气流磨结构,因此它兼有二者的 ...

由于此网站的设置,我们无法提供该页面的具体描述。

2016年6月2日 · 凹凸棒粉粉磨机表凹凸棒粘土产品的企业标准企业产品名称规格特性盱眙凹凸棒石粘土公司白云石凹凸棒粉,,, 烧失量企业产品名称规格特性盱眙凹凸棒石粘土公司白云石凹凸棒 17_凹凸棒土磨粉机,凹凸棒粉磨机_上海百业网 2014年12月10日凹凸棒土 ...

2012年10月13日 · 拉伯尔镍选厂、阿根廷阿卢姆百雷拉铜金矿、美国国 家钢铁公司球团厂、澳太利亚芒特艾萨铅锌选矿厂 等等。这种流程由全自磨一球磨流程演变而来,该 流程有很多变化。有些选厂的半自唐机排矿用泵扬 送给筛子,筛上物料自流返回半自磨机,如幽家钢铁

因此,预粉磨设备的预粉磨效果(用C值进行衡定)是影响设备选型规格的一个关键因素。 5、结论 1)预粉磨设备规格、入磨物料细度、磨机的内部结构是联合粉磨系统提产降耗的三个要素。 2)预粉磨设备选型应该遵循公式A=2μB/C。

使用气流粉碎机加工,物料平均粒度细可达到145微米,且可任意调节粒度段,是电池材料行业不可缺少的加工设备。那么问题来了,气流粉碎机能粉碎到什么程度?跟以下因素有关系:1、原料的初始细度,气流粉碎机一般要求进料在50目以下。

由于此网站的设置,我们无法提供该页面的具体描述。