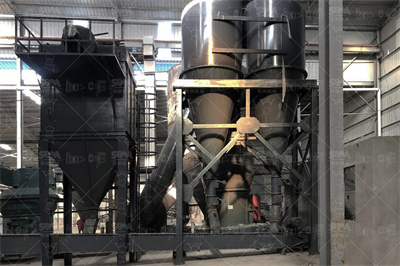

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2025年4月9日 · 第三节 中国磨粉机行业存在的问题 第四节 中国磨粉机行业解决问题的策略分析 第十四章 年中国磨粉机行业研究结论及投资建议 第一节 观研天下中国磨粉机行业研究综述 一、行业投资价值 二、行业风险评估 第二节 中国磨粉机行业进入策略分析

上海科利瑞克机器有限公司是国内的矿山磨粉设备研发和生产的高新技术企业, 公司自主产权的HGM系列超细微粉磨粉机以及超大型立式磨粉机系列产品十多个型号,并数十项国家技术创新, 是名副其实的矿石微粉专家!

2017年6月20日 · 高压辊磨机的投产不但取得了节能降耗的效果,而且使主厂房的入磨粒度由20 ~0mm,并实现了将合格粗粒尾矿提前抛弃送往排土场堆存的目的,其主厂房的磨矿负荷及细粒尾矿的浓缩输送量显著减少,从而提升了选厂的整体生产能力,缓解了尾矿库库容不足对产

2023年7月31日 · 一系列措施都会刺激机制砂的需求, c时拉破碎筛分等矿山机械行业的市场需 求。 国内矿山机械行业竞争格局有望优化。 ¢内矿山机械制造业的区域化特征较 为明显,主要集中在江苏、山东、河等地。 ¢内矿山机械行业市场化竞较为

2024年1月18日 · 年中国磨粉机行业深度研究与发展趋势研究报告,首先介绍了磨粉机行业市场发展环境、磨粉机整体运行态势等,接着分析了磨粉机行业市场运行的现状,然后介绍了磨粉机市场竞争格局。随后,报告对磨粉机做了重点企业经营状况分析,最后分析了磨粉机行业发展 .

2024年7月10日 · 根据贝哲斯咨询矿物磨粉机市场调研数据显示,2023年全球矿物磨粉机市场规模达到了亿元(人民币),中国矿物磨粉机市场规模达到了 亿元。 针对预测

2025年4月15日 · 第三节 中国立式磨粉机行业存在的问题 第四节 中国立式磨粉机行业解决问题的策略分析 第十四章 年中立式磨粉机行业研究结论及投资建议 第一节 观研天下中国立式磨粉机行业研究综述 一、行业投资价值 二、行业风险评估

2025年3月20日 · 一、中国摆式磨粉机行业市场集中度影响因素分析 二、中国摆式磨粉机行业市场集中度分析 第七章 年中国摆式磨粉机行业模型分析 第一节 中国摆式磨粉机行业竞争结构分析(波特五力模型) 一、波特五力模型原理 二、供应商议价能力 三、购买者议价

以磨粉机为研究对象,结合国内先进磨粉机和国外领先磨粉机发展现状,对我国磨粉机未来发展方向进行展望,为磨粉机研究人员提供参考. 展开 关键词:

2010年2月4日 · 进入三季度以来,矿石粉碎机械行业发展形势明显好转。 实践证明,粉碎机械企业通过加强自主创新、推进结构调整,在国家扩内需、保增长的政策落实过程中抓住了大好时机。今年1—9月,矿石粉碎机械龙头企业黎明重工科技股份有限公司累计营业额与2008年同比增 .

2021年7月23日 · 为了提高我国磨粉机行业的整体品牌,加快中国磨粉机行业的发展步伐,由中国好口碑品牌推荐榜发起了2021年度"磨粉机十大品牌" 评选活动,活动于7月21日落下帷幕。此次活动有五十多家磨粉机品牌报名参加,最后,到底有哪些品牌进入榜单前十呢?

2012年3月21日 · 我国的磨粉机械市场需求主要分布在能源系统、三大化工、石油工业及矿山采选中。60年代我国联合设计了F型磨粉机械和Y型油机械。从80年代开始,以沈机械、大耐、上机械为主的国内主要生产厂开始引进国外先进技术,经过消化吸收,产品陆续投放市场。

2006年3月1日 · 2010年5月建冶全体员工为世博喝彩,上海世博会组委会组织了名企闪耀矩阵"闪耀世博、寻找坐标"展示活 动:招募优秀企业参与,通过民企馆现场和网络同步展出,让更多中小民营企业参与盛会,上海建冶重工机械有限公司也积极参与此次活动,通过承办方严格审核获此百年 .

2016年10月28日 · 立磨粉机作为目前世界上前沿的磨粉机设备,得到广泛应用,那么目前立磨在国内外应用以及研究究竟是什么状况呢?本文作一个阐述。 1 立磨机在国内外的研究现状 1. 1 立磨在国外的发展 第一台立磨是在 1925 年诞生,由德国专家开发出来的。

矿山机械是直接用于矿物开采和富选等作业的机械。包括采矿机械和选矿机械。探矿机械的工作原理和结构与开采同类矿物所用的采矿机械大多相同或相似,广义上说,探矿机械也属于矿山机械。另外,矿山作业中还应用大量的起重机、输送机、通风机和排水机械等。

2015年9月10日 · 介绍了球磨机、半自磨机、棒磨机、搅拌磨机等国内外常用磨机的性能特点和最新研究进展,并对其发展方向进行了展望。 自19 世纪意大利ICF 公司设计制造的用于陶瓷工 .

2010年5月25日 · "据了解,该公司多位高级工程师紧跟国内外磨粉行业的发展趋势,自主研发的一款革命性、创新型磨粉机——HC1700 ... ① 凡本网注明"来源:中国粉体网"的所有作品,版权均属于中国粉体网,未经本网授权不得转载、摘编或利用其它方式使用。

2019年12月14日 · 立式磨粉机是在广泛采用国内外先进技术的基础上,结合多年的各种磨机生立式磨粉机产经验,设计开发的先进粉磨设备。是一种集破碎、干燥、粉磨、分级输送于一体的磨粉行业理想设备。可广泛应用于水泥、电力、冶金、化工、非金属矿等行业。

2020年2月27日 · 2 国内外研究现状与进展 目前国内外对粉碎能耗的研究主要集中在粉碎的三大经典理论、能耗─粒径尺寸之间的量化关系及实际应用、降低能耗等方面,而关于谷物摩擦生热的研究文献却很少。 物料粉碎能耗的研究 经典粉碎理论及其新观点

摘要 以磨粉机为研究对象,结合国内先进磨粉机和国外领先磨粉机发展现状,对我国磨粉机未来发展方向进行展望,为磨粉机研究人员提供参考。 以磨粉机为研究对象,结合国内先进磨粉机和国外 .

2019年10月14日 · 虽然各个公司生产的立式磨粉机的结构形式不同,但所有的立式磨粉机的粉磨原理是相同的。立式磨粉机在我国粉磨行业的兴起和发展比发达国家晚 20 到 30 年左右,当今我 .