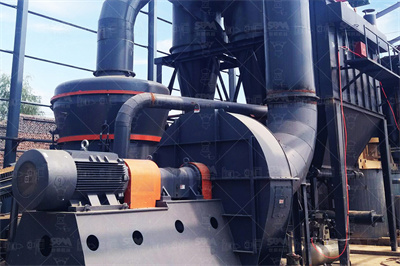

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

凝灰岩主要成分是火山灰,颜色有紫红色、灰白色、灰绿色等等,形状有块状、层状等等,在建筑领域应用较为广泛。凝灰岩的加工首要工序就是破碎,而破碎凝灰岩就需要用凝灰岩破碎机,为此红星机器根据凝灰岩的物理和化学性质,并在颚式破碎机的基础上研制了一款凝灰岩专用的破碎设 .

另外 Athi River地Ⅸ存 大量 的凝灰岩,该类大 然 火 山灰质材料容易粉磨,活性一般,町以作为补充料源。 设备选 型 以较 为 难 磨 的 simba火 山 渣 为 基 准 考虑 .。 摘 要 :为 生 产 出 .

2013年7月9日 · 日立建机 (中国)有限公司 安徽派雅新能源股份有限公司 安徽东维太阳能科技有限公司 ... 庐江县关庙含铁凝灰岩 矿 庐江县矾山矿业有限公司 安徽金安管业集团钟山矿业科技发展有限公司 ...

2023年10月21日 · 一种凝灰岩助磨剂、采用其的凝灰岩粉及低碳多元胶凝材料.pdf,本发明公开了一种凝灰岩助磨剂、采用其的凝灰岩粉及低碳多元胶凝材料。本发明所述低碳多元胶凝材料包括低热硅酸盐水泥、凝灰岩粉、活性二氧化硅粉、萘系减水剂及无氯盐化合物,其中凝灰岩粉由凝灰岩与凝灰岩助磨剂混合研磨至 ...

欢迎来到淘宝网选购滑石粉铝矾土研磨机 凝灰岩粉磨机 水泥混凝土磨粉机 矿山雷蒙磨, 淘宝数亿热销好货,官方物流可寄送至全球十地,支持外币支付等多种付款方式、平台客服24小时在线、由商家提供退换货承诺、让你简单淘到宝。

阿里巴巴花岗岩 石灰石 高钙石 玄武岩磨粉机 辉绿岩 凝灰岩 混合料雷蒙磨,研磨机,这里云集了众多的供应商,采购商,制造商。 这是花岗岩 石灰石 高钙石 玄武岩磨粉机 辉绿岩 凝灰岩 混 .

2025年4月25日 · 桂林鸿程专业制造磨粉机,有立式磨粉机,雷蒙磨粉机,超细环辊磨粉机等矿山设备,经过多年的技术研究和创新,咨询热线: 固定电话:

2021年11月23日 · 凝灰岩是一种岩浆和沉积岩之间过渡中的一种岩石,经过加工后的凝灰岩可用在建材、农业、化工等多个行业领域中。常用到的设备有鄂式破碎机、锤式破碎机、反击式破碎机、振动给料机等,下面本文就来对以上凝灰岩加工过程中经常使用到的设备进行详细分析一下。

2021年12月2日 · 摘要: 火山灰凝灰岩有作为掺合料应用于西部地区水利工程建设的前景。采用扫描电子显微镜(SEM)、X射线衍射分析(XRD)和X射线荧光分析(XRF)等手段,研究了粉磨作用对凝灰岩物理性能、化学成分和物相组成的影响,分析了凝灰岩活性指数与粉磨时间、养护龄期的相关关系。

一种能够粉碎物品的作业元件。应力消耗: 8 su/RPM 获取 动力合成器 动力合成。 用途 物品加工 粉碎轮可执行"粉碎"类的配方,没有配方的物品会被直接销毁。由于大部分"粉碎"配方与"研磨"配方相重合,因此在处理物品方面,粉碎轮可代替大部分 石磨 的职能。

阿里巴巴氢氧化钙雷蒙磨粉机 2024油页岩新型磨粉机械 凝灰岩雷蒙磨,粉碎机,这里云集了众多的供应商,采购商,制造商。这是氢氧化钙雷蒙磨粉机 2024油页岩新型磨粉机械 凝灰岩雷蒙磨的详细页面。品牌:黎明重工,货号:,适用物料:铁矿石,高岭土,石英,硫磺,粘土,石膏,肥料,金矿石,硅石 ...

凝灰岩粉 磨机 黑钨矿加工 铝钒土机械 钽矿加工机械 铜矿研磨机 稀土矿粉磨机 水泥熟料碎石机 耐火粘土破碎生产线 石灰粉制作工艺 800目腻子粉机械 人造石机器 辽阳粉石机启东系列大蒜去 .

凝灰岩是一种 火山碎屑岩,其组成的火山碎屑物质有50%以上的颗粒直径小于2mm,成分主要是 火山灰,外貌疏松或致密,有层理的称为层凝灰岩,颜色多样,有紫红色、灰白色、灰绿色等。根据其含有的火山碎屑成分,可以分为:晶屑凝灰岩; 玻屑凝灰岩;岩屑 凝灰岩。

2023年10月7日 · 将凝灰岩石粉作为矿物掺合料掺入水泥基材料中,可实现减少水泥产量、降低CO2等温室气体排放和利用工业固废。本文综述了凝灰岩石粉在水泥基材料中的作用机理,并系统总结了凝灰岩石粉掺入对水泥基材料的凝结时间、和易性、力学性能、耐久性能的影响规律,给出了凝灰岩石粉制备和使用建议 ...

2025年1月2日 · 该系列产品主要适用于建材、冶金、化工、电力等工矿企业粉磨各种矿石及其它可磨性物料。 可用于开流粉磨,也适用于与选粉机组成的循环圈流粉磨。 具有对物料适应性强 .

2024年11月19日 · PFRM系列水泥生料立式粉磨机 VPM 系列立式预粉磨机 矿用磨机 原料磨 水泥生料立式磨 球磨机 关于鹏飞 公司简介 ... 江苏鹏飞集团的粉磨 设备系统产品有:球磨机、立式磨、矿用磨机、原料磨、风扫煤磨、辊压机、破碎机、收尘器、选粉机以及控制系统 ...

2020年4月14日 · 郑州破石机厂家生产的立轴冲击式制砂机制砂效果好,能够生产出高等的立方体砂石骨料,它成功助力于山东混凝土骨料生产,加快了当地高速公路的黎明,促进了地区与地区间的经济文化交流结构简单,安装、维修方便,运行成本低。 细度合乎规格的粉子,随风流进入旋风收集器,经出粉管排出 ...

凝灰岩立式粉砂机钛矿研磨机熟料制作机械萤石粉立磨杂砂岩机械设备沙石加工方解石 粉磨机海沙加工设备硬岩磨粉机金矿砂加工机械石灰石粉精加工碎石加工机器绿浑岩精凝灰岩生产流程石灰石精加工烟煤生产流程石料生产流纹岩浑绿岩粉磨机蛭石粉机械铅 LM立式悬辊磨粉机 MTW欧版磨粉机 TGM超压 ...

2020年3月26日 · 凝灰岩成品石子 需要配置哪些凝灰岩 破碎设备?凝灰岩的硬度比石灰岩稍高,而且主要成分为石英,具有一定的腐蚀性,所以破碎主要选耐磨、耐腐蚀的颚破、圆锥破 进行粗碎和中碎。细碎制沙主要选 冲击式制砂机,不但效率高、而且粒

![凝灰岩 (Tuff) [MC]我的世界原版 (Minecraft) MC百科|最大 ...](/bzn2vgy/67.jpg)

介绍 凝灰岩(Tuff)是一种纹理上多孔的岩石方块。生成 凝灰岩会在主世界Y ≤ 0 的区域呈团簇状生成,每区块尝试生成 2 次,团簇大小为 0~64 个方块。 凝灰岩还会在主世界Y= 60~8 的区域与铁矿石相伴生成,形成铁矿脉。 用途 可用于装饰,也可用于合成凝灰岩装饰方块。

2016年10月6日 · 破碎是凝灰岩加工中主要的步骤,凝灰岩破碎设备有很多,下面就市场上销量广、使用多的颚式破碎机、圆锥破碎机为大家进行分析。 1、颚式破碎机 颚式破碎机是一款坚固耐用、历史悠久的一款凝灰岩破碎设备,它是凝灰岩进行粗破的必备设备,在市场上备受广大用户的青睐,该设备所具有的优势 ...

凝灰岩粉磨机器上海重工. 详细马可波罗网()提供上海昌磊机械成套设备有限公司相关企业介绍及产品信息主要以凝灰岩欧版粉磨机为主,还包括了凝灰岩欧版粉磨机价格、凝灰岩 .

2021年4月26日 · 当前,矿业行业的主要粉磨设备主要有:球磨机、雷蒙磨、立式磨机、辊压机、机械冲击磨、振动磨等,其选型对粉磨工艺至关重要,会直接影响到矿产资源的利用率、生产成本、产品质量和经济效益。接下来,我们就分别说说这些磨粉机械设备,以及适用对象分别是什么。

2023年10月21日 · 1.本发明涉及一种凝灰岩助磨剂、采用其的凝灰岩粉及低碳多元胶凝材料,属于建筑材料技术领域。适用于水工混凝土所需的胶凝材料制备。背景技术: 2.在建筑材料领域中水泥是最常用的胶凝材料,以水泥为胶凝材料制备的水泥混凝土和水泥砂浆等水泥基材料,广泛应用于土木工程建设中。

2023年12月21日 · 凝灰岩磨粉机是一种重要的粉磨设备,主要用于凝灰岩和其他材料的粉磨加工。 它的用途广泛,广泛应用于水泥、建材、冶金等行业的生产中。 凝灰岩磨粉机的种类和工作特 .

2010年3月5日 · 凝灰岩是一种火山碎屑岩,外貌疏松或致密,有层理的称为层凝灰岩,是常用的建筑材料,也可作为制造水泥的原料和提取钾肥的原料,然而凝灰岩用什么破碎机才适用?这里给大家介绍下相关内容,并提供凝灰岩破碎生产线工艺流程。

甘肃省第56个世界地球日主题宣传活动周启动 甘肃新闻|胡昌升在甘南陇南调研时强调 科学施策加强地质灾害综合治理 全力保障人民群众生命财产安全