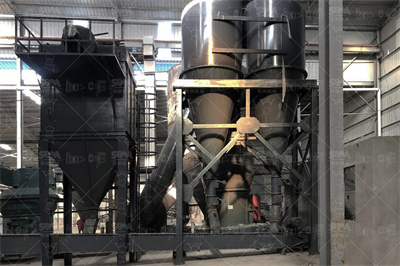

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2 天之前 · 粉煤灰制备铝硅钛合金项目可行性研究报告方案可用于发改委立项及银行贷款2013详细案例范文编制机构:博思远略咨询公司360投资情报研究中心研究思路:关键词识别:1粉煤灰制备铝硅钛合金项目可研 2粉煤灰制备铝硅钛合金市场前景分析预测 3粉煤灰制

2018年4月17日 · XSD洗砂机生产线专业供应商上海科利瑞克机器有限公司专业提供XSD洗砂机洗砂机等设备! 名 称:上海科利瑞克机器有限公司 认 证:工商信息已核实 访问量:

5 天之前 · 炉渣粉碎机简介: 要想实现炉渣的真正价值,首先要对炉渣进行破碎。一般的破碎机破碎炉渣破碎细度不达标,破碎过程中容易发生赌塞,生产能力小,破碎效果不理想,总是被顾 .

回转反吹扁袋除尘器适用于水泥制造、建筑耐火材料、粮食加工、铸造、机械制造、冶金,具有高效、低阻、结构紧凑、维护 ...

2018年4月17日 · 锤式破碎机是由上海科利瑞克机器有限公司独家生产,专业应用于矿石石粉加工,细度高,产量大。 名 称:上海科利瑞克机器有限公司 认 证:工商信息已核实 访问量:

2022年9月9日 · HGM80微粉磨机专业提供商上海科利瑞克机器有限公司,专业提供矿石微粉磨粉机,加工细度高,产量大,欢迎咨询!

2019年3月22日 · 一种纯丙轻质颗粒炫岩真石漆及其制备方法专利检索,一种纯丙轻质颗粒炫岩真石漆及其制备方法属于··多糖或其衍生物专利检索,找专利汇即可免费查询专利,··多糖或其衍生物专利汇是一家知识产权数据服务商,提供专利分析,专利查询,专利检索等数据服务功能。

2018年4月17日 · PC400x600锤式破碎机是由上海科利瑞克机器有限公司独家生产,专业应用于矿石石粉加工,细度高,产量大。 名 称:上海科利瑞克机器有限公司 认 证:工商信息已核实 访问量:

2020年4月25日 · 产品品牌: 河南富兰重工机械有限公司. 产品型号: YGM65型

2013年11月11日 · tags:方解石破碎机多少钱,山东方解石破石机报价多少,河北方解石粉碎机价格多少 方解石是一种碳酸钙矿物,天然碳酸钙中最常见的就是它。 因此,方解石是一种分布 .

2020年6月27日 · 郑州汉丰机械设备有限公司提供庆阳煤块破碎机质量如何什么牌子图片,技术文章,行业资讯,如果您对我公司的产品服务感兴趣,请联系我们,欢迎点击访问或来电问询!

2 天之前 · 国税总局:商品和服务税收分类与编码(试行)(二) 2016商品和服务税收分类与编码(试行)(电子件) 2027 1 08 01 04 03 01 蒸压加气混凝土板 以硅质材料和钙质材料为主要原

2018年5月28日 · 河北淀粉包装机 * 阀口型定量包装机(颗粒体机型) 组成部分:高低气压控制系统、回气收尘系统、对夹阀装置、压力控制系统、称重控制系统、PLC控制系统等。 工作原理:利用称重系统、PLC控制气压快、中、慢加料。 产品亮点:解决了传动加料机构的机械磨损及转动部件对颗粒体及流动较差粉体 ...

世界方解石矿主要分布的国家 方解石资源分析报告百度文库 方解石分为大方解和小方解石及冰州石,中国的方解石主要分布在广西,江西,湖南一带。 主要交通线(铁路为主)两侧,方解石矿的分布:广西的铁路主要有湘桂线、黔桂线、南凭线、南昆线、南防线及南湛线等数条。

2018年4月11日 · 名 称:上海科利瑞克机器有限公司 认 证:工商信息已核实 访问量:

6 天之前 · 废烟支处理机生活视频搜狐视频生活视频:废烟支 处理机 首页 电视剧 内地 美剧 韩剧 英剧 自制剧 电 影 爱情 喜剧 科幻 悬疑 影院 综 艺 搞笑 情感 访谈 真人 脱口秀 动 漫 冒险 搞笑 益智 亲子 魔幻 废烟烟丝回收机百度百科废烟支烟丝回收设备,主要由回潮筒、烘烤筒、喂料机、破碎机、两条振槽 ...

2022年2月23日 · 双环式破碎机?是一种新型原料粉碎机内装两套破碎转子,上下两级粉碎从而形成了中破细破一机化。该机克服了因原料含水份大粘结篦底,不易出料的缺陷,具备生产效率高,粉碎效果好等优点。

2021年2月8日 · 方解石经历一系列粉碎、制砂、筛选分级等步骤后,可制成好质量的成品方解石砂,整个环节针对破碎机的挑选非常主要,只有挑选性价比提升的机械,即可为客户获取更大经济利润,在这里推举大家挑选新乡鼎力机器生产的方解石破碎机,其不但构造优势典型,并且报价对比低廉,可以为客户获取 ...

矿山粉碎雷蒙机特别提醒此价格仅为小型粉碎机磨粉机主机价格,整机价格根据设备实际配置另计。 技术参数参数机型磨辊数(个)磨辊高度磨辊直径磨环内径产品图片产品特点产品特点:本机由主机、分析机、鼓风机、电磁振动给料机、储料斗、管道系统等组成。

2021年11月29日 · 名 称:桂林矿山机械有限公司 认 证:工商信息已核实 访问量:

优质二手摇摆颗粒机 二手颗粒粉碎机 二手制样粉碎机 涡轮粉碎机 矿渣磨粉用立磨还是雷蒙磨好 立式磨粉机干法磨粉 31 年经验厂家 MTW138磨粉机 石油焦粉生产设备 辊式磨粉机的零件结构 .

方解石主要成分为碳酸钙,主要用途是做重钙粉和轻钙粉,不同细度的方解石粉广泛的应用于造纸、医药、化工、农业等多个领域。 网站首页 产品中心 方解石磨粉机,方解石粉碎机,方解石制 .

双转子锤式细碎机:适用于方解石、石灰岩、砖瓦厂的炉渣、矿渣 、页岩、建筑垃圾、建筑废料等物料粉碎,解决了用矸石作砖厂添加料、内燃料;用矸石、页岩生产标砖、空心砖高湿物料粉 .

2018年4月4日 · 名 称:上海科利瑞克机器有限公司 认 证:工商信息已核实 访问量:

2014年11月14日 · 本页面包括了河沙相关的所有发明专利、实用新型专利、外观设计专利,用户可以对河沙相关的专利数据进行查询检索,也可以进行河沙相关专利数据的批量下载导出甚至于统计分析。

2021年2月8日 · 方解石经历一系列粉碎、制砂、筛选分级等步骤后,可制成好质量的成品方解石砂,整个环节针对破碎机的挑选非常主要,只有挑选性价比提升的机械,即可为客户获取更大经济利润,在这里推举大家挑选新乡鼎力机器生产的方解石破碎机,其不但构造优势典型,并且报价对比低廉,可以为客户获取 ...

2019年8月13日 · 敲击方解石可(kě)以得到很(hěn)多(duō)方形碎块,故名方解石。 方解石在自然界分(fēn)布极广,是一种碳酸钙矿物(wù),天然碳酸钙中比较常见的就是它。