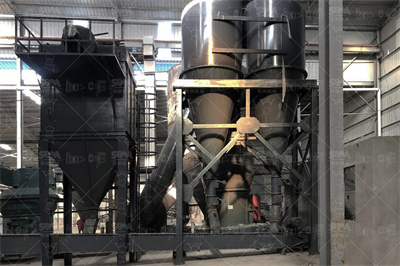

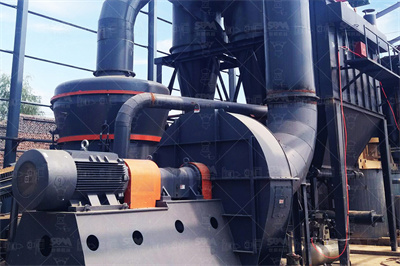

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2016年6月27日 · 石膏粉加工生产线的过程中主要有破碎系统、粉磨系统、输送系统等,使用的设备有很多,下面我们就来简单对石膏粉生产线中使用的破碎设备、磨粉设备以及输送设备进行 .

2016年1月19日 · 泰安汇森石膏建材()主营纸面石膏板生产线,建筑石膏粉生产线,脱硫石膏处理生产线,石膏砌块生产线,无纸石膏板生产线等生产设备,为客户定制系统方案,承做石膏建材生产线的工艺、设备、安装、调试、培训等交钥匙工程。

本实用新型涉及一种工业化α高强石膏生产装置,属于α高强石膏的工业化生产领域。背景技术石膏是世界公认的绿色环保节能的新型材料,特别是α高强石膏物化性质比水泥更具优越性,可作为水泥制品的替代品。国家也在"十三五"期间也接连出台了相应的推动政策,工信部发布《绿色制造工 .

2022年7月3日 · 1、墙体找平 在装修中石膏粉一般用来做基层处理的,比如填平缝隙、阴阳角调直、毛坯房墙面第一遍腻子找平等。石膏的粘接度好,不易产生脱落现象,在用来进行墙面找平时,一般并不是直接使用石膏粉的,里面也会加入滑石粉,否则施工会 ...

通过掌握这些步骤,可以制作出符合需求的石膏模具,为各个领域的产品制作提供便利。 制作石膏模具所需的主要材料是石膏粉和水。石膏粉是一种由石膏石煅烧而成的粉末状材料,可以在建材市场或工艺品材料店购买到。 三、制作模具 1.

2021年8月9日 · 一、石膏板废料可以做什么 石膏板废料可以做什么 建筑石膏板废料以及在陶瓷生产中却产生大量的废旧石膏模具(石膏模具使用后的废石膏),可以再经过煅烧,研磨,少量地加入半水石膏粉用。亦可卖给水泥工厂,作为水泥的添加物,用以调节水泥凝固速度。

2022年3月9日 · 建筑石膏粉生产线通常根据技术要求分为石膏开采工艺、破碎、研磨和煅烧工艺。 如果颚式破碎机破碎的石膏不能满足粒度要求,可以配备圆锥破碎机、锤式破碎机、反击式破碎机等二级石膏破碎设备,对石膏进行进一步的中细.

2009年4月3日 · 建筑石膏(即β半水石膏,或称普通石膏粉)物理强度低,主要用于纸面石膏板、石膏砌块和部分装饰材料,用途、用量均有限。而高强石膏(即α半水石膏)物理强度一般为普通石膏粉的3倍以上,因此它不仅能够替代建筑石膏以降低成本,而且它的用途更为广泛,例如:干燥抗压强度在25兆帕~40 ...

2021年12月8日 · 由于工业副产石膏的存量和产量巨大,能够适应各类副产石膏原料的转晶设备的研发成为石膏转晶设备的发展方向。 3.工业副产石膏常用的转晶设备主要有两类:连续式转晶设备和间歇式转晶设备,从设备的传热形式上,可分为内加热和外加热式两类;从工艺方式上,分为干法和液相法两种。

2023年3月11日 · 1.本发明属于石膏粉加工领域,尤其涉及一种石膏粉用高效复合破碎筛选一体化设备。背景技术: 2.石膏粉通常为白色通常为白色通常为白色通常为白色、无色透明晶体称为透石膏,有时因含杂质而成灰浅黄、浅褐等色。 石膏粉是五大凝胶材料之一,在国民经济中占有重要的地位,广泛用于建筑 ...

2023年3月27日 · 【制作传统石膏豆腐】1.泡豆:挑选优质黄豆500 克,用多于黄豆重3倍的清水浸没黄豆,夏天浸泡6 小时左右(天热应及时换水, 以防豆浆酸败),春秋季10小时左右, 冬天 12 小时左右,浸泡时间不宜过长或太短,以掰开黄豆两瓣光滑即可;2.磨浆 ...

其中,石膏石膏被用作骨折固定和矫正的辅助材料。通过将石膏粉与适量的水混合,迅速凝固成为石膏,可用来制作石膏绷带,用于固定断骨,帮助骨折复位和愈合。此外,石膏粉还用于牙科材料的制备,例如石膏模型可以用于牙科矫正的治疗规划和制作。 3.化工

本实用新型涉及一种石膏粉生产设备领域,尤其是涉及一种石膏粉称重出料装置。背景技术石膏粉通常为白色、无色,无色透明晶体称为透石膏,有时因含杂质而成灰、浅黄、浅褐等色。条痕白色。透明。玻璃光泽,解理面珍珠光泽,纤维状集合体丝绢光泽。解理极完全,和中等,解理片裂成 .

石膏干燥后的石膏需要进行粉磨处理,以获得所需的石膏粉。常用的石膏粉磨碎设备 有研磨机、球磨机和立式磨机等。 石膏脱硫 石膏脱硫是整个工艺流程的第一步,其目的是将烟气中的二氧化硫通过化学反应转化为石膏。常用的脱硫方法包括湿法 ...

石膏娃娃的正确做法以及制作流程有了熟石膏粉和好的模具,下边就是如何制作石膏娃娃了,制作娃娃步骤如下:一、材料及工具:模具,熟石膏粉,碗,勺,水桶,小盆,小刀,搅拌棒(或筷子),塑料片,夹子若干,挂钩若干. 二、新模具使用前的准备工作 ...

经选粉机将粉磨后达到产品所需细度的石膏生粉送入沸腾炉进行煅烧,煅烧后的合格石膏粉送入熟料仓储存或送入制品车间使用。 生产细度:100目和325目. 石膏是一种用途广泛的工业材料和 .

2023年12月13日 · 石膏粉成套设备是指将原料加工成石膏粉的一整套生产设备,包括破碎、磨粉、煅烧、冷却、筛分等环节。 石膏粉成套设备具有自动化程度高、生产效率高、产品质量稳定等 .

泰安路发节能环保设备有限公司于2020年04月27日成立,公司成立之初依托于泰安杰普石膏专业的技术和行业经验,在石膏粉设备行业得以迅速发展,拥有20余年行业经验,致力于推广工业副产石膏(磷石膏,脱硫石膏等)在石膏建材行业应用。

2014年5月5日 · 石膏粉磨粉生产线使用的设备主要包括颚式破碎机(粗碎)、反击式破碎机、欧版梯形磨粉机等,其中黎明重工生产的欧版梯形磨粉机性能稳定,能耗低;可调可控成品粒度、 .

2010年4月22日 · 陶瓷生产用石膏粉的种类 在陶瓷生产中,成形模型的制作和一些胎型的制作都会使用石膏粉。市场上有满足陶瓷注浆成形、滚压成形、冷压成形、母模胎型制作用的各种石膏粉。 注浆成形用石膏粉 陶瓷生产中采用注浆成形的品种较多。

2024年12月31日 · 建筑石膏生产线 _石膏粉生产工艺流程_ 脱硫石膏烘干煅烧线 工作总结 建筑石膏生产线作为现代建筑材料生产的重要一环,其高效运作与产品质量直接关系到建筑行业的可持续发展。这条生产线不仅融合了先进的工艺技术与设备,还承载着对市场需求的灵活响应与满足。

8.完成:最后,将制作好的石膏娃娃放在一个干燥通风的地方,等待所有涂料和清漆充分干燥。 注意事项 在制作石膏娃娃时,请注意以下几个事项: •石膏粉:可以在艺术用品店或在线购买。选择质量好的石膏粉,以保证最终制作出来的娃娃质量良好。

本发明属于三废治理及综合利用的技术领域,具体涉及一种钛白粉厂废弃物红石膏的回收利用方法及其设备。背景技术: 红石膏是采用硫酸法生产钛白粉时,为治理酸性废水,加入石灰(或电石渣)以中和大量的酸性废水而产生的以二水石膏为主要成分的工业废渣,是硫酸法钛白粉主要的工业 .

2023年3月21日 · 石膏粉的生产工艺 1、煅烧块石膏,然后再粉碎。这种方法首先是将石膏放在土窑中煅烧,煅烧完成后再用 球磨机 将其粉碎,就可以得到相关粒度的熟石膏粉,这种制作石膏粉的*有点主要体现在设备简单,煅烧效率高,缺点是煅烧不均匀,容易混入煤炭等杂质。

2024年1月2日 · 本文将详细介绍生产石膏粉所用的设备,包括破碎机、磨粉机、除尘器等,并探讨如何选择合适的设备以提高生产效率和产品质量。 临沂金皓机械有限公司

经过粉磨系统的物料由粒径0~30mm,改变为80~120目,符合石膏粉细度要求。 2.先烧后磨工艺流程采用9FC800型磨粉机 对于细度要求在低于240目的石膏粉,此磨机是最经济最实用的。结构简单,维修维护量极少,设备成本低廉,生产成本大大降低。 图 35

合乎细度要求的细石膏粉成品(CaOSO42H2O)进入可控平稳的输送设备(闸板阀、卸料阀、提升机及螺旋输送机),再输送到下一个系统进行煅烧。 气流从除尘器的进入鼓风机。 整个空 .

2022年4月25日 · 石膏作为一种常用的工业材料和建筑材料,可用于生产 水泥缓凝剂、石膏建筑制品、模型制作、医用食品 添加剂、硫酸生产、纸张填料、油漆填料等。 石膏经过煅烧、磨细可得建筑石膏,又称熟石膏、灰泥。若煅烧温度为190 °C可得模型石膏,其细度和白度均比建筑石膏高。

2021年6月9日 · 石膏娃娃手工制作技巧 一: 模具 准备 (1)检查:模具内壁是否洁净有无破损,每次脱完模要清除模具内壁的石膏残余,一天工作结束用水清洗模具内外后静放,不可泡在水里等第二天再用(否则拿出的模具内壁有水会与已凝固的石膏起反应做出石膏娃娃不合格)

2011年3月24日 · 煅烧石膏粉的设备有很多种,我是做石膏粉煅烧设备和和石膏板生产线的,我给你推荐几套设备,先说一下 石膏粉煅烧设备;1 利用内烧式回转窑煅烧石膏粉设备,该设备由 回转窑,烟气沸腾炉和袋式除尘器,上料设备组成。