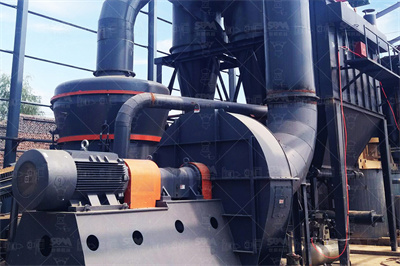

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2024年10月15日 · 雷蒙磨粉机使用说明书一、主要结构及工作原理该机结构主要由主机、分析器、成品旋风分离器、微粉旋风分离器及风管组成。其中,主要由机架、进风蜗壳、铲刀、磨辊、磨环、罩壳及电机组成。工作时,将需要粉碎的物料从主机罩壳侧面的进料斗加入机内,依靠悬挂在主机梅花架上的磨辊装置 ...

创新性磨环、磨辊设计,优化圆弧形咬合方式,与传统老式雷蒙磨相比,降低了物料通过粉磨区下落速度,延长了碾压粉碎时间,兼具了雷蒙磨机宽泛的进料粒度要求及超细磨机超细化粉碎功 .

2025年3月6日 · R型雷蒙磨机广泛适用于重晶石、方解石、钾长石、滑石、大理石、石灰石、白云石、萤石、石灰、活性白土、活性炭、膨润土、高岭土、水泥、磷矿石、石膏、玻璃、保温材 .

2024年5月18日 · 要包括粉碎、雷蒙磨、焙烧、浸取、碳化、干燥和包装。 (a)粉碎工段 天青石粉碎:天青石由装载机从天青石大棚运至天青石粉碎工房 装入天青石料斗,由往复式给料机送入颚式破碎机破碎,然后由密闭

2025年3月17日 · 雷蒙磨是一种广泛应用于矿石、建材、化工等行业的高效研磨设备,主要用于将各种非金属矿物研磨成细粉。以下是雷蒙磨的工作原理的详细解析: 雷蒙磨的工作原理 1.物料 .

2025年3月5日 · 雷蒙磨粉机在石灰石加工领域备受瞩目,其通过磨辊的强力碾压力实现精细粉磨,内置精密分级系统确保粉体细度精准调控。 该设备适用于莫氏硬度7级以下、湿度6%以内的 .

由于此网站的设置,我们无法提供该页面的具体描述。

雷蒙磨粉机生产厂家,提供全套雷蒙磨设备及技术支持。了解雷蒙磨的价格、型号及维护技巧,欢迎咨询!

红星机器生产的雷蒙磨机 一机多用,满足不同成品实现80800目范围内的自由组合生产,欢迎来电咨询.

2022年3月23日 · 天青石如何磨成粉 天青石如何磨成粉?当然是用现代机械设备,有雷蒙磨粉机升级版,也有超细粉立磨,可以将天青石磨成粉600目,用于生产碳酸锶,应用于电视机显像管的生产和用于制造彩电阴极射线管、电磁铁、锶铁氧体、烟火、荧光玻璃、信号弹等,也是生产其他锶 .

CR1700雷蒙磨粉机专为玻璃、橡胶、农药、搪瓷、油漆、磷肥及造纸等多个化工行业设计,适用于粉磨莫氏硬度七级以下、湿度不超过6%的非易燃易爆物料。