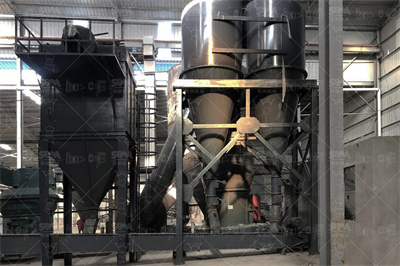

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2023年12月24日 · 您在查找阿特拉斯扳手拆解分解图吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

2025年1月8日 · 乌萨斯突击者 乌萨斯突击者队长 帝国炮火先兆者 帝国炮火中枢先兆者 帝国前锋精锐 帝国前锋百战精锐 萨卡兹宿主百夫长 萨卡兹宿主卫巢百夫长 "皇帝的利刃" 乌萨斯平民 斗士塔露拉 塔露拉 梅菲斯特,"歌者" "不死的黑蛇"

2025年3月22日 · 您在查找阿特拉斯破碎锤修理全过程吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

2009年3月23日 · 双螺杆压缩机阿特拉斯操作说明书零件手册6 零件手册ZH离心机阿特拉斯 AC 阿特拉斯 3075KW 使用维护零件手册 说明书 AIIS45406 GA 30+75 液压破碎锤培训手册 阿特拉斯空压机零件手册GA 11+, GA 15+, GA 18+, GA 22+, GA 20 空

2023年10月23日 · 您在查找"阿特拉斯扳手拆解分解图短视频信息"吗?抖音短视频帮您找到更多精彩的阿特拉斯 视频内容!让每一个人看见并连接更大的世界,让现实生活更美好 精选 推荐 探索 直播 放映厅 短剧 搜索 您是不是在找: 手把焊横焊正确方法 ...

2017年12月19日 · 阿特拉斯HB2200液压破碎锤零件手册.pdf 36 页 内容提供方:skvdnd51 大小: 字数: 约万字 发布时间: 发布于浙江 浏览人气: 165 下载次数: 仅 .

2025年4月17日 · 您在查找阿特拉斯电动扭力扳手拆解图吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

2019年5月21日 · 工作原理 阿特拉斯 HB2000 型破碎锤打击机构主要 由上缸体、中缸体、下缸体和活塞组成,如图 1 所示。 下缸体上端面螺纹孔镶嵌有螺纹丝套, 上缸体、中缸体、下缸体通 .

3 天之前 · 契约与审判之神·密特拉:男。人类 【龙族】 光明与太阳之神·巴哈姆特:男。黄金巨龙 【亡灵族】 冰霜与死亡之神·奥西里斯:男。巫妖 【海族】 海洋与生命之神·提亚马特:女。海兽 【兽人族】 战争与毁灭之神·贝希摩斯:男。黄金比蒙 【巨人族】

铁甲工程机械网整机频道阿特拉斯科普柯破碎锤栏目,为您提供全的阿特拉斯科普柯破碎锤品牌.阿特拉斯科普柯破碎锤报价.用户评价,阿特拉斯科普柯破碎锤图片.阿特拉斯科普。

《(新式标点)三门街》 三门街下,第六十一回论姻缘母子谈衷曲泄言语姊妹吐真情 话说李广等入府第修饰的修饰起造的起造各人又修了家书差人驰往木藉迎接各位太夫人足足忙。 三门街下涵盖原著全文和白话文版本,有详细的释义、注解与注释,助你理解深意。

2021年6月16日 · 懂车帝特斯拉蔚来粉碎式拆解频道为您提供最全的特斯拉蔚来粉碎式拆解大全,涵盖特斯拉蔚来粉碎式拆解怎么样,特斯拉蔚来粉碎式拆解好不好,特斯拉蔚来粉碎式拆解怎么找等信息,想了解更多关于特斯拉蔚来粉碎式拆解信息就来懂车帝。

6 天之前 · DOUBLE TUNE鹅卵石蓝牙耳机限时特惠; 华硕B850M主板994元限时优惠; 大水牛镜界正叶ARGB风扇限时特价元; 雷柏M218无线鼠标促销,PLUS会员价

2009年3月23日 · 双螺杆压缩机阿特拉斯操作说明书零件手册6 零件手册ZH离心机阿特拉斯 AC 阿特拉斯 3075KW 使用维护零件手册 说明书 AIIS45406 GA .

铁甲网致力于为您提供全面的阿特拉斯科普柯hb7000破碎锤图解信息汇总!包括阿特拉斯科普柯hb7000破碎锤图解相关新闻资讯、用户口碑评论、精彩视频等,让您全面了解行业动态、热门 .

2025年3月22日 · 您在查找阿特拉斯165破碎锤拆解吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

2025年3月22日 · 您在查找阿特拉斯破碎锤内部结构图吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

2017年2月7日 · ETDDS945020ST (A ) Product No. 8433 0760 88 ServAid Spare part list Ref. No. 8 9 (1031) 10 11 12 (1316) 13 14 (1516) 15 16 17 18 (1922) 19 20 ...

阿特拉斯HB2000,2200液压锤使用维修这是笔者根据自己的维修经验,归纳总结的,绝对可以帮助你如何维修此类型的液力锤,保证维修效果。 首页 文档 视频 音频 文集

2025年3月22日 · 您在查找阿特拉斯分解图零件图吗? 抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。 更有海量高清视频、相关直播、用户,满足您的在线观看需求。

2024年6月10日 · 阿特拉斯通压机配件更换,今天来给一台二十二的设备换铁盒阀包。设备是开机的时候顶大闸, 这个故障已经判断完了。啊,这是信号牌有问题,现在师傅正在拆解这边的都是拆下来的旧件,然后师傅现在正在拆的这个是主体部分, 这个是未更换的旧品新件。

2024年12月4日 · 您在查找阿特拉斯破碎锤拆解吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

阿特拉斯空压机分解图零件手册ZE230255_,阿特拉斯空压机分解图零件手册ZE230255_,手册,零件,ZE255,pdf,零件手册,阿特拉斯,空压机,零配件,空气压缩机,ZE,手册,零件,ZE255,pdf,零件手册,阿特拉斯,空压机,零配件, 空气压缩机 ...

2024年5月17日 · 您在查找阿特拉斯破碎锤拆卸图片吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

2025年3月22日 · 您在查找阿特拉斯钻锤拆解视频吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。