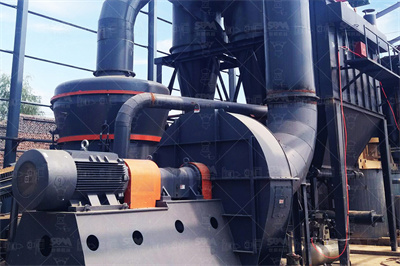

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2020年9月29日 · 该领域下的技术专家 如您需求助技术专家,请点此查看客服电话进行咨询。 1、张老师:1.探索新型氧化还原酶结构功能关系,电催化反应机制 2.酶电催化导向的酶分子改造 .

2017年11月16日 · 碎纸机是粉碎销毁日常机密文件的机器。它由"切纸刀棒"和"电机"两大主体组成,中间通过齿轮将两者紧密联系在一起,电机带动齿轮传动,把能量输送到刀轴,刀轴带动刀 .

2016年11月26日 · 机械原理课程设计—碎纸机设计说明书电子版.doc,2012年机械原理课程设计 碎纸机 设计者: 学号: 学号: 学号: 指导老师: 2012年6月21日~7月5日 目录 一 设计题目 二 .

2023年5月14日 · 使用碎纸机时,将纸张插入机器的出纸口,然后按下启动钮即可将纸张切成小块或细条。 ... 这种方法虽然效率较低,但也可以达到纸张粉碎的 目的。总的来说,纸张粉碎是 .

碎纸机粉碎的纸屑可以回收再利用,但需要根据纸屑尺寸和用途选择适当的方法。

2020年11月8日 · 爱普生(中国)有限公司事业部总经理袁雪解释道,我们看得到的只是放旧纸、出新纸,其实机器里主要经过三步工艺:第一步是纤维分离,同时清除旧纸上所有墨水和碳 .

2018年12月8日 · 其原理是把废旧纸张粉碎后,在一定温度和压力下进行纤维重组,然后就能产生新纸。有点星际迷航里的物质重组机的感觉——当然没那么高科技,只能用于标准复印纸的重 .

2023年3月22日 · 该领域下的技术专家 如您需求助技术专家,请点此查看客服电话进行咨询。 1、贺老师:氮化物陶瓷、光功能晶体材料及燃烧合成制备科学及工程应用 2、杨老师:工程电磁 .

2017年3月27日 · 记者随后联系到了几个生产散浆的负责人,终于见识到了散浆生产的全过程。粉尘弥漫的厂房里,堆积如山的纸尿裤废料、随地丢弃的纸尿裤次品未经任何消毒,经过几台机 .

刀片(Blade)是刀具、武器或机器的一部分,其边缘设计成用于刺穿、切割或刮擦材料表面。 刀片可以由诸如燧石,金属(通常是钢),陶瓷或其他材料制成。 刀片是人类最古老的工具之 .

稻草。详情>>查看"制成纸筋粉用什么碎纸机"的全部个含义纸筋粉价格_纸筋粉价格查询_造价通造价通纸筋粉材价查询平台,专业提供各地全纸筋粉价格、纸筋粉。碎纸机碎过的纸有什么用:023 .

2010年3月16日 · 普通的纸如何变成 纸浆 有没有什么办法可以把普通的纸,如报纸,信纸等(餐巾纸除外)快一点变成纸浆。我把报纸撕碎泡水里泡了好几天仍然是一张张的不糊。有没有什么 .

2023年2月3日 · 墙面抹灰的机具有: 1. 抹灰机:是一种电动工具,可以将石膏、水泥等材料均匀地涂抹在墙面上,提高施工效率。2. 抹刀:是一种手动工具,用于将石膏、水泥等材料均匀地 .

2013年8月23日 · 2019年2月26日 准确的说,一般家用的粉碎机可以回收,粉碎到一定尺寸以下的碎纸,无法再回收利用了。比如有的高密级碎纸机,要把纸切成特别碎的纸粉,不能送去造纸厂了。在 .

2020年12月3日 · 碎纸机是做什么用的碎纸机在我们的日常生活中很常见,在办公的时候经常用到。碎纸机的最大作用,无疑是保密。那么,碎纸机的主要作用有哪些呢?一、对于企业来说, .

2022年2月5日 · 滚切式纸壳粉碎机,纸壳破碎机 1:1 ; 1:1 ; 1:1 产品价格: 元/台 产品品牌:恒吉机械 产品分类:无 发货地址:郑州巩义 有效期至:长期有效 推送专题:未设置 .

由于此网站的设置,我们无法提供该页面的具体描述。

2017年6月20日 · 加强,于是一种碎纸的工具变诞生了。碎纸机是粉碎销毁日常机密文件的机器。它由"切纸 刀棒"和"电机" 两大主体组成,中间通过齿轮将两者紧密联系在一起,电机带动齿轮 .

2021年5月18日 · 1 2012年机械原理课程设计 碎纸机 设计者: 学号: 学号: 学号: 指导老师: 2012年6月21日7月5日 東華學 目录 一设计题目 二设计任务 三机器的功能分析 四碎纸机的发 .

2024年9月26日 · 慢速碎纸机的工作原理: 慢速粉碎 机使用低速、高扭矩切割系统来减小坚硬材料的尺寸。它们的效率和功率使它们对废物管理和回收等行业至关重要。但要让这些机器保持满 .

2012年6月21日 · 12012年机械原理课程设计碎纸机设计者:学号:学号:学号:指导老师:2012年6月21日~7月5日2目录一设计题目二设计任务三机器的功能分析四碎纸机的发展五运动方案设计六运动 .

2016年9月21日 · 本机主要采用固定刀盘和动刀在内向低速运转中产生的剪切力将物料*破碎,适用于将废纸如硬纸板、纸板,废纸、纸张、纸板、纸筒、纸盒、纸管、纸芯、书本、废旧纸箱、 .

由于此网站的设置,我们无法提供该页面的具体描述。

2021年12月13日 · 十碎纸机的使用注意事项及保养 十一设计小结 十二参考资料 3 一设计题目 设计一台能制动粉碎纸张的粉碎机。操作者将一叠规格相同的待粉碎的纸张 放入碎纸机的集纸器, .

2020年10月17日 · 特点:保密等级:5级,2*10mm的碎纸尺寸符合财务高保密要求,拥有涡轮散热系统使得机器可连续碎纸60分钟,大约可碎3000张纸。这个碎纸量非常适合财务月末、季末、 .

由于此网站的设置,我们无法提供该页面的具体描述。

2019年7月20日 · 碎纸机是粉碎销毁日常机密文件的机器。它由"切纸刀棒"和"电机"两大主体组成,中间通过齿轮将两者紧密联系在一起,电机带动齿轮传动,把能量输送到刀轴,刀轴带动刀 .

由于此网站的设置,我们无法提供该页面的具体描述。

欢迎来到淘宝网选购纸厂废料粉碎机纸筋加工机器票据酒盒破碎机, 淘宝数亿热销好货,官方物流可寄送至全球十地,支持外币支付等多种付款方式、平台客服24小时在线、由商家提供退换货 .

2023年2月28日 · 加强,于是一种碎纸的工具变诞生了。" " " " 碎纸机是粉碎销毁日常机密文件的机器。它由 切纸刀棒 和 电机 两大 主体组成,中间通过齿轮将两者紧密联系在一起,电机带动 .

2011年12月8日 · 古德坚定地回答说:"当然不行!赛事提供的模拟问题要简单许多,每张纸的 碎片都被分开了。而实际情况中,要面对的是被碎成一大箱碎片的一沓文件,所以实际问题要复杂 .

2024年11月28日 · 您在查找怎么把纸打成超细的粉末吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

碎纸机是用于粉碎的机器或设备。 切碎系统用于减小给定材料的尺寸。 虽然大多数在线字典将碎纸机定义为"用于粉碎文件的设备,作为防止身份盗用的安全措施",但粉碎机可以根据所处理 .

由于此网站的设置,我们无法提供该页面的具体描述。