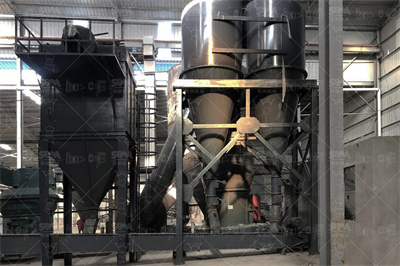

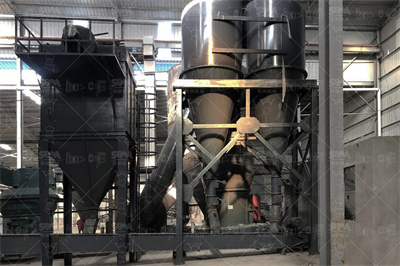

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

2023年10月17日 · 圆盘式气流磨,无传动部件,自分级的粉碎设备,埃尔派20年技术积淀,实力值得信赖! 圆盘式气流磨的工作原理: 气流粉碎机与旋风分离器、除尘器、引风机组成一整套粉碎系统。压缩空气经过滤干燥后,通过拉瓦尔喷嘴高速喷射入粉碎腔,在多股高压气流的交汇点处物料被反复碰撞、磨擦 ...

电动机通过 立式减速机 带动磨盘旋转,固体原料通过锁风给料装置从进料口进入磨盘中心,在离心力场的作用下被甩向磨盘的周边并受到磨辊的反复碾压而粉碎。 粉碎后的物料从磨盘的边缘溢出,其中的粉状物料被从机器下部上升的高速气流带起,上升的气流和粉状物料经过磨机上部的选粉 .

秸秆粉碎机品牌/图片/价格 秸秆粉碎机品牌精选大全,品质商家,实力商家,进口商家,微商微店一件代发,阿里巴巴为您 ...

查看、比较30种海量低温粉碎机产品信息,直接联系国内外知名品牌厂商(Retsch/莱驰, FRITSCH, NTE Process, ...),提供询盘报价、图片、规格、价格、经销网点查询。找专业优质低温粉碎机,上DirectIndustry(工业在线展会) 全球工业采购平台。

阿里巴巴为您找到7,314个今日最新的气流粉碎机价格,气流粉碎机批发价格等行情走势,您还可以找万能粉碎机,木材粉碎机,饲料粉碎机,超细气流粉碎机,锯末粉碎机,气流粉碎机 江苏,塑料粉碎机,气流式超微粉碎机,流化床式气流粉碎机,超细粉碎机市场价格、批发价格等相关产品的价格信息。

阿里巴巴为您找到15,882个今日最新的小型粉磨机价格,小型粉磨机批发价格等行情走势,您还可以找市场价格、批发价格等相关产品的价格信息。阿里巴巴也提供相关小型粉磨机供应商的简介,主营产品,图片,销量等全方位信息,为您订购产品提供全方位的价格参考。

圆盘粉碎机品牌/图片/价格 圆盘粉碎机品牌精选大全,品质商家,实力商家,进口商家,微商微店一件代发,阿里巴巴为您 ...

粉碎机刀片品牌/图片/价格 粉碎机刀片品牌精选大全,品质商家,实力商家,进口商家,微商微店一件代发,阿里巴巴为您 ...

2 天之前 · 一、QL系列气流粉碎机产品概况: 本机采用了旋转二次风淘洗技术,避免了过粉碎现象,从而达到了粒度集中,有效控制大粒的产生,并达到节能效果。 二、QL 系列气流粉碎机工作原理: 气流磨的工作原理,是以高压气体产生得超音速气流带动物料进行自身碰撞粉碎。

2022年4月14日 · 石头粉碎机多少钱一台?本文为大家详细解答。 一方石头可以加工多少方石子? 答:一方石头可以加工方石子。 石子的重量与其粒径的大小有关,粒径大空隙较多,密度就小,而粒径小空隙少,者密度就大,这样一方石子的重量也就并非固定。

阿里巴巴为您找到2065条一吨粉碎机产品的详细参数,实时报价,价格行情,优质批发/供应等信息。

阿里巴巴为您找到56,556个今日最新的粉磨机价格,粉磨机批发价格等行情走势,您还可以找市场价格、批发价格等相关产品的价格信息。 阿里巴巴也提供相关粉磨机供应商的简介,主营产品, .

2023年10月17日 · 山东埃尔派粉体科技有限公司生产的环辊磨是非金属矿理想粉碎机,产量大、粉碎粒度能达气流磨细度、效率高、运行成本低,生产过程清洁环保、设备安装方便易调节.了解辊压磨粉碎机的参数、价格、图片,24小时咨询电话.

实验室粉碎机也称为实验室环磨机或实验室粉碎机。是制样的关键设备之一。高效准确的实验室分析依赖于良好的样品制备。体面的多磨碗系列实验室粉碎机是实验室环磨机,专为高生产率和耐用寿命而设计和制造,为您的实验室提供并支持准确可靠的结果。

2023年11月30日 · NSTJ系列扁平式气流粉碎机研发于上世纪六十年代,至今在超细粉碎领域仍是不可被替代的主流机型,该机器内衬有刚玉陶瓷型、不锈钢型供用户选择,不污染物料、不产生升温,细度<5μm,可达纳米级。是超细粉碎的

大型粉碎机品牌/图片/价格 大型粉碎机品牌精选大全,品质商家,实力商家,进口商家,微商微店一件代发,阿里巴巴为您 ...

九阳(Joyoung) 磨粉机家用料理机五谷杂粮干磨粉碎机超细电动不锈钢打粉机中药材小型研磨机辅食料理机JYSM01 1100ml大容量、不锈钢杯体、四页刀片、500W纯铜电机、不锈钢杯体、两档调速

沈飞QLM系列气流粉碎机参数沈飞粉体沈飞QLM系列气流粉碎机参数及最新价格,公司客服电话7*24小时为您服务,售前/ 售后均可咨询 中国粉体网欢迎您! 登录 个人登录 企业登录 注册 APP 粉享通 广告服务 微信 关注微信公众号 中国粉体网 移动端 粉体展 ...

阿里巴巴为您找到4556条粉末研磨机产品的详细参数,实时报价,价格行情,优质批发/ ... 多功能粉碎机研磨破壁打粉超细三七药材粉碎磨粉机干粉机粉末大料 广州波茂商贸有限公司 1年

同传统的辊式磨粉机、细碎机、辊压机、各类冲击式粉碎机相比具有显著的优势,真正实现了预粉技术的高效、节能、环保。 1、设计新颖、结构合理。

粉磨机品牌/图片/价格 粉磨机品牌精选大全,品质商家,实力商家,进口商家,微商微店一件代发,阿里巴巴为您找到85,630个有实力的粉磨机品牌厂家,还包括价格,高清大图,成交记录, .

2023年12月13日 · 我们这里一共为您找到21个粉磨机产品报价信息,其中有7个产品提供了报价,其中最低价格为元, 最高价格为元,平均价格为70807元。,您也可以马上 .

自动锤式旋风磨是一种外形美观、结构紧凑、操作简便、运转平稳、经久耐用的粉碎设备。 高速恒温自动锤式旋风磨是主要适用于粮食行业的小麦、稻谷等中小颗粒 (水份含量符合国家标准)样 .

2009年3月21日 · 【喷射式磨机】喷射式磨机价格_喷射式磨机批发_喷射式磨机厂家_Hc... 无锡中泰SVP喷射混合器 武汉良品精致婚纱摄影公司 ¥万 /个 询价 ...钻磨机 立磨机 石粉磨机 微磨机 水泥磨机 手扶磨机 斜磨机 升降磨机 ...