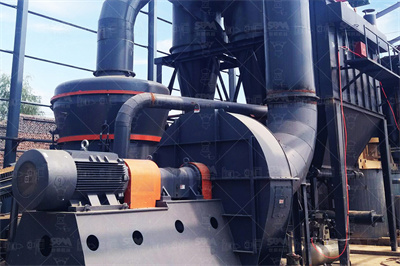

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

阿里巴巴为您找到169条煤炭 立磨机产品的详细参数,实时报价,价格行情,优质批发/ 供应等信息。 共 169件 煤炭 立磨机 相关产品 所有类目 实力商家 买家保障 进口货源 支持支付宝 材质保障 综合 销量 价格 确定 起订量 以下 确定 所有地区 ...

2023年8月18日 · 煤炭立磨今日价格、最新报价、行情走势来自于我的钢铁网门户网站,为您提供煤炭立磨产业资讯信息,包含最新的煤炭立磨今日价格、煤炭立磨行情走势、煤炭立磨最新报价、行业分析等信息,为国内钢铁企业,钢材企业提供最新的煤炭立磨汇总资讯。

阿里巴巴为您找到72条小型磨煤机产品的详细参数,实时报价,价格行情,优质批发/ ... 江西柏立松科技环保设备制造有限公司 9年 月均发货速度: 暂无记录 江西 石城县 ¥ 金矿石连续式球磨机 干湿两用选金设备 磨煤机东弘选矿球磨机配件 ...

阿里巴巴为您找到1,641个今日最新的立磨机价格,立磨机批发价格等行情走势,您还可以找市场价格、批发价格等相关产品的价格信息。阿里巴巴也提供相关立磨机供应商的简介,主营产品,图片,销量等全方位信息,为您订购产品提供全方位的价格参考。

2025年4月25日 · HMM系列碗式磨煤 机 HZS系列制砂机 最新资讯 为您提供企业、市场行业资讯 高效驱动 价值领航!12台套HCM185摆式磨助力客户打 ... 【钢厂立磨】【炉渣立磨】【石灰立磨】 【石墨立磨】【重钙专用立磨】【粗粉立磨】 HLMX 超细立式磨粉机 【碳酸钙 ...

阿里巴巴为您找到582条矿石 立磨机产品的详细参数,实时报价,价格行情,优质批发/ 供应等信息。 共 582件 矿石 立磨机 相关产品 所有类目 实力商家 买家保障 进口货源 支持支付宝 材质保障 综合 销量 价格 确定 起订量 以下 确定 所有地区 ...

2025年1月17日 · 江西兰炭立磨今日价格、最新报价、行情走势来自于我的钢铁网门户网站,为您提供江西兰炭立磨产业资讯信息,包含最新的江西兰炭立磨今日价格、江西兰炭立磨行情走势、江西兰炭立磨最新报价、行业分析等信息,为国内钢铁企业,钢材企业提供最新的江西兰炭立磨汇总资讯。

阿里巴巴为您找到3,877个今日最新的江西煤炭价格,江西煤炭批发价格等行情走势,您还可以找市场价格、批发价格等相关产品的价格信息。 阿里巴巴也提供相关江西煤炭供应商的简介,主营产 .

阿里巴巴为您找到1532条立磨机产品的详细参数,实时报价,价格行情,优质批发/供应等信息。

水泥立式磨机品牌/图片/价格 水泥立式磨机品牌精选大全,品质商家,实力商家,进口商家,微商微店一件代发,阿里巴巴 ...

立磨的优点和发展史中国水泥技术网 立磨是一种理想的大型粉磨设备,广泛应用于水泥、电力、冶金、化工、非金属矿等行业。 型立磨、的型立磨、天津水泥工业设计研究院的TRM 了各种类型和型号的水泥窑系统近2000套,生料、水泥和煤粉的磨机约5600台。

阿里巴巴为您找到543条矿石 立磨机产品的详细参数,实时报价,价格行情,优质批发/ 供应等信息。 共 543件 矿石 立磨机 相关产品 所有类目 实力商家 买家保障 进口货源 支持支付宝 材质保障 综合 销量 价格 确定 起订量 以下 确定 所有地区 ...

2025年4月2日 · 近期,在国家发展改革委统一部署下,江西省发改委指导各地发改部门会同市场监管等部门组成核查组,对部分煤炭贸易企业涉嫌超出价格合理区间销售煤炭的线索进行了核查 .

2025年4月22日 · 提供今日煤炭价格,如煤炭,煤炭价格,煤炭价格行情,最新煤炭价格查询,煤炭质量指标, 煤炭价格走势图等煤炭信息相关资讯 欢迎访问金投原油()!, 黄金 .

LM立磨工作时,主电机通过减速机驱动磨盘旋转,同时热风从进风口进入磨室,物料从下料口落到磨盘中央,并在离心力作用下由中央向边缘移动。 当物料经过磨盘上的辊道粉磨区域时,受到磨辊的碾压,大块物料被破碎,细粒物料则形成料床进行粒间粉碎。

2025年4月28日 · 免费查询更多二手立磨机价格详细参数、实时报价、行情走势、优质商品批发/供应信息等,您还可以发布询价信息。

阿里巴巴为您找到355条lm 立式磨机产品的详细参数,实时报价,价格行情,优质批发/ ... 石灰厂专用立式磨粉机煤炭立磨 磨粉机lm1300煤粉制备立磨 桂林鸿程矿山设备制造有限责任公司 18年 ...

5 天之前 · 煤炭市场网是集煤炭新闻、煤炭市场分析、煤炭价格、煤炭数据的综合性煤炭资讯平台,涵盖煤炭产量、煤炭销量、煤炭消费、煤炭港口、煤炭库存、煤炭进出口、煤炭运输等核心 .

2023年10月20日 · 立磨机凭借其优势,深受业内人士喜爱,目前有6种机型,煤粉立磨机、立式矿磨机、矿渣立磨机、水泥熟料预粉磨立磨机、水泥立磨机、高细立磨机,又有50款型号可选择,每小时产量6420吨,成品细度(20400 目),具体见下面立式磨粉机技术

2024年12月13日 · 江西焦炭立磨今日价格、最新报价、行情走势来自于我的钢铁网门户网站,为您提供江西焦炭立磨产业资讯信息,包含最新的江西焦炭立磨今日价格、江西焦炭立磨行情走势、江西焦炭立磨最新报价、行业分析等信息,为国内钢铁企业,钢材企业提供最新的江西焦炭立磨汇总资讯。